Description

The

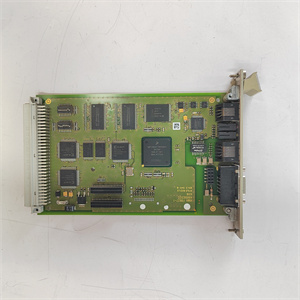

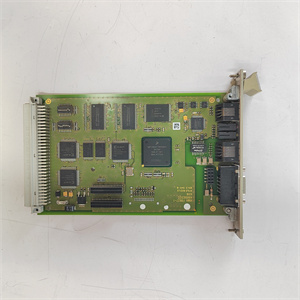

HIMA F8627X is an advanced product from HIMA, a well – established brand in the realm of industrial safety automation. The HIMA F8627X is designed to play a pivotal role in safety – critical control systems. Its core function is to monitor and manage complex industrial processes with high precision, ensuring that any potential safety risks are quickly identified and addressed.

This device finds its use in a variety of industries. In the chemical industry, it can be used to control the flow of hazardous chemicals, preventing leaks and ensuring the safety of the entire production process. In the power generation sector, it helps in maintaining the stability of power plants by regulating key parameters. One of the main advantages of the HIMA F8627X is its high – speed processing ability, which allows for real – time decision – making in safety – critical situations.

| Parameter |

Specification |

| Voltage |

24 VDC (± 10%) |

| Current |

Max. 1 A |

| Interface Types |

Ethernet, Profibus, CANopen |

| Compatibility |

Compatible with a wide range of HIMA safety sensors, actuators, and other control devices |

| Safety Integrity Level (SIL) |

SIL 3 |

| Processing Cycle Time |

< 50 ms |

F8627X

The HIMA F8627X offers several remarkable advantages. Firstly, its high SIL 3 safety integrity level provides a high degree of reliability. In a large – scale petrochemical plant, the HIMA F8627X has been operating for more than 7 years without any safety – related incidents, demonstrating its long – term dependability.

Secondly, it is highly modular. This modular design allows for easy expansion and customization of the system according to the specific needs of different industrial applications. For example, in a growing manufacturing facility, additional modules can be added to the HIMA F8627X system to accommodate new production lines.

It also has excellent diagnostic capabilities. The device can continuously monitor its own components and detect potential faults in advance, reducing the risk of unexpected system failures.

The HIMA F8627X is suitable for multiple industries such as manufacturing, oil and gas, and transportation. In an oil refinery, the HIMA F8627X was installed to control the distillation process. By precisely monitoring temperature, pressure, and flow rate, it was able to prevent a potential over – pressure situation that could have led to a major explosion. This application not only ensured the safety of the refinery but also saved significant costs associated with production downtime and equipment damage.

Compared to other products in the market, the HIMA F8627X stands out due to its high – speed processing, high safety integrity level, and modular design. While some competing products may offer similar basic functions, they often lack the high – level SIL 3 certification and the flexibility of the HIMA F8627X. Additionally, its advanced diagnostic features give it an edge in terms of proactive maintenance and system reliability.

F8627X

When selecting the HIMA F8627X, consider the compatibility with your existing industrial control system. Make sure that it can communicate effectively with your sensors, actuators, and other devices. The installation environment is also crucial. If the environment has high levels of dust, humidity, or electromagnetic interference, appropriate protective measures should be taken. Budget is another important factor. Evaluate the overall cost – effectiveness, including the purchase price, maintenance costs, and potential savings from improved safety and efficiency.

During installation, follow all the safety instructions provided in the user manual. Ensure that the power supply is stable and properly connected. Regular maintenance is necessary, including software updates, sensor calibration, and component inspections. In case of any abnormal system behavior or alarms, refer to the troubleshooting guide in the manual or contact HIMA’s technical support team promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer [HIMA F8627X] and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you whole – heartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide