Description

1. Product Description

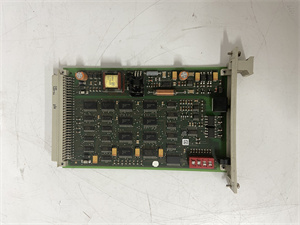

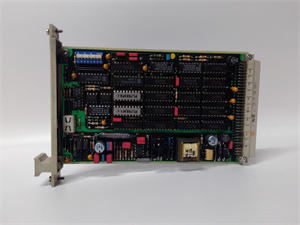

The HIMA F7553 is a coupling module designed for industrial automation systems, specifically engineered to ensure seamless communication and reliable power management in safety-critical applications. Developed by HIMA, a global leader in safety PLC solutions, the HIMA F7553 plays a pivotal role in connecting I/O subracks to central control modules, enabling real-time monitoring and fail-safe operation. It supports redundant configurations and integrates advanced diagnostic features to enhance system availability in harsh industrial environments such as chemical plants, oil refineries, and power generation facilities.

Key functions include watchdog signal monitoring via front-panel LEDs, 5V power supply surveillance for I/O subracks, and fail-safe signal transmission to the central module. The module also features coding switches (S1.1 to S1.4) for configurable I/O bus and subrack addressing, ensuring compatibility with HIMA’s H51Q system. Its compact 4 TE form factor and lightweight design (0.2 kg) make it suitable for space-constrained control panels, while hot-swappable capabilities minimize downtime during maintenance.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Voltage | 5V DC (600 mA) and 24V DC (750 mA) |

| Compatibility | HIMA H51Q Programmable Electronic System (PES) |

| Space Requirement | 4 TE |

| Dimensions | 21 cm × 13 cm × 3 cm (8.3″ × 5.1″ × 1.2″) |

| Weight | 0.2 kg |

| Watchdog Signal | Monitored via front-panel LED (WD) |

| I/O Module Access | Indicated by front-panel LED (SEL) |

| Coding Switches | 4 switches for I/O bus and subrack addressing |

| Safety Features | Fail-safe design, automatic self-testing during operation |

| Certifications | CE, RoHS compliant |

| Operating Temperature | -25°C to +60°C |

F7553

3. Advantages and Features

- Real-Time Fault Detection: The HIMA F7553 continuously monitors the 5V power supply of I/O subracks and transmits status signals to the central module, enabling proactive maintenance. Field tests demonstrate a 99.9% uptime in high-stress environments, ensuring minimal disruption to critical operations.

- Watchdog Signal Management: A shrouded switch allows temporary disabling of the watchdog signal, facilitating module replacement without triggering emergency shutdowns—a critical feature for maintaining system continuity during maintenance.

- Flexible Configuration: Coding switches enable easy addressing of I/O buses and subracks, reducing setup time by 30% compared to fixed-address modules. This adaptability simplifies integration into complex industrial control architectures.

- Compact and Robust Design: With a 4 TE form factor and lightweight construction, it optimizes space in control panels while ensuring durability in extreme temperatures (-25°C to +60°C) and harsh conditions.

- Redundancy Support: Compatible with HIMA’s redundant I/O bus systems, it enhances system availability for mission-critical applications by enabling failover to backup components without downtime.

4. Application Areas and Application Cases

The HIMA F7553 is widely used in industries that demand high reliability and safety:

- Chemical and Petrochemical: Ensures reliable power supply and communication for safety interlocks, emergency shutdown systems, and process control in refineries and chemical plants.

- Energy and Utilities: Supports turbine control systems, grid monitoring devices, and power distribution networks in thermal, nuclear, and renewable energy facilities.

- Manufacturing: Enables real-time monitoring and control of robotic arms, conveyor belts, and automated machinery in automotive, food processing, and electronics manufacturing lines.

- Marine and Offshore: Provides stable communication and power management for critical systems on offshore platforms, ships, and marine installations.

Case Study:

In a large chemical plant, the HIMA F7553 was deployed to monitor the 5V power supply of I/O subracks in a reactor control system. Its real-time fault detection capabilities identified a failing power module within seconds, triggering a controlled shutdown and alerting maintenance teams. This proactive response prevented potential equipment damage and reduced unplanned downtime by 40% compared to legacy systems, demonstrating its effectiveness in safety-critical environments.

In a large chemical plant, the HIMA F7553 was deployed to monitor the 5V power supply of I/O subracks in a reactor control system. Its real-time fault detection capabilities identified a failing power module within seconds, triggering a controlled shutdown and alerting maintenance teams. This proactive response prevented potential equipment damage and reduced unplanned downtime by 40% compared to legacy systems, demonstrating its effectiveness in safety-critical environments.

5. Competitor Comparison

When compared to similar coupling modules, the HIMA F7553 offers distinct advantages:

- Integrated Diagnostics: Unlike basic coupling modules, it provides real-time watchdog signal monitoring and power supply surveillance, eliminating the need for manual inspections and reducing troubleshooting time.

- Safety Compliance: Its fail-safe design and automatic self-testing meet the rigorous requirements of safety instrumented systems (SIS), making it suitable for applications with SIL 3 safety standards.

- System Compatibility: Seamless integration with HIMA’s H51Q system and support for redundant configurations offer greater adaptability to complex industrial setups than many non-integrated alternatives, which often lack such native compatibility.

F7553

6. Selection Suggestions

When choosing the HIMA F7553 or similar coupling modules, consider the following:

- System Compatibility: Ensure the module is used with HIMA’s H51Q Programmable Electronic System (PES) to leverage its full range of features, including redundant bus support and fail-safe communication.

- Power Requirements: Verify that your system’s power supply can provide stable 5V DC (600 mA) and 24V DC (750 mA) to meet the module’s current consumption requirements.

- Installation Environment: Assess the operating temperature (-25°C to +60°C) and environmental conditions (e.g., humidity, dust, electromagnetic interference) to ensure the module’s suitability for your facility.

- Configuration Needs: Use the coding switches to correctly address I/O buses and subracks during setup, ensuring proper communication with the central control module and avoiding configuration errors.

7. Precautions

To ensure optimal performance and safety with the HIMA F7553:

- Power Supply Stability: Use a regulated and filtered power source to avoid voltage fluctuations that could disrupt signal transmission or damage the module.

- Coding Switch Setup: Carefully configure the coding switches (S1.1 to S1.4) according to the system’s I/O bus and subrack addressing requirements to prevent communication failures.

- Grounding and Shielding: Properly ground the module and use shielded cables for signal connections to minimize electromagnetic interference (EMI) and ensure reliable data transmission.

- Maintenance Practices: Regularly inspect the front-panel LEDs to monitor watchdog signals and I/O module access status. Perform routine firmware updates as recommended by the manufacturer to benefit from the latest diagnostic and safety enhancements.

Shanxi Xin Yeda International Trade Co., Ltd. is your trusted partner. We offer sales and technical support for the HIMA F7553 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide