Description

The

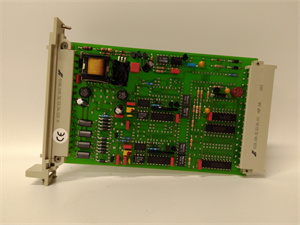

HIMA F6706 is a high-reliability safety controller module designed to meet the stringent demands of industrial safety-critical applications. As a key component of HIMA’s safety automation solutions, the

HIMA F6706 is engineered to provide precise control and monitoring, ensuring the safe operation of machinery and processes in hazardous environments.

This module serves as the core processing unit for safety systems, enabling real-time data analysis, logic execution, and communication with peripheral devices. The HIMA F6706 is built to withstand harsh industrial conditions while delivering consistent performance, making it an ideal choice for industries where safety and reliability are non-negotiable. Its robust design and advanced functionality help minimize downtime and reduce the risk of accidents, contributing to overall operational efficiency.

| Parameter |

Specification |

| Type |

Safety controller module |

| Voltage Supply |

24 V DC (±10%) |

| Power Consumption |

≤15 W |

| Processing Speed |

High-speed logic execution (≤1 μs per step) |

| Memory Capacity |

8 MB flash memory, 4 MB RAM |

| Communication Interfaces |

Ethernet (10/100 Mbps), PROFIBUS DP |

| Safety Integrity Level |

SIL 3 (IEC 61508), AK 6 (DINV 19250) |

| Operating Temperature |

-40°C to +70°C |

| Compatibility |

HIMA HIMax and HIMatrix safety systems |

| Redundancy Support |

Hot-swap redundancy for critical applications |

HIMA F6706

The HIMA F6706 stands out for its exceptional safety performance and operational resilience. It is certified for SIL 3, the highest safety integrity level, ensuring it can handle the most critical safety functions in industrial settings. The module incorporates advanced diagnostic capabilities, continuously monitoring its own health and detecting potential faults with a diagnostic coverage rate of over 99%, which helps prevent unexpected failures.

One of its key features is seamless integration with HIMA’s safety architecture, allowing for easy configuration and scalability. The HIMA F6706 supports hot-swapping, enabling maintenance or replacement without shutting down the entire system, which is crucial for maintaining productivity in 24/7 operations. Additionally, its low power consumption and wide temperature range make it suitable for both harsh outdoor environments and energy-efficient setups.

The HIMA F6706 is widely used in industries such as chemical processing, oil and gas, power generation, and manufacturing, where safety systems are essential to prevent accidents and comply with regulatory standards. It is particularly suited for applications like emergency shutdown systems, fire and gas detection, and machinery safety control.

Case Study: A major petrochemical plant in the Middle East deployed the HIMA F6706 to upgrade its safety instrumented system (SIS). The module’s high-speed processing and SIL 3 certification ensured rapid response to critical events, such as detecting a gas leak and initiating a shutdown within milliseconds. This implementation reduced the plant’s safety risk by 40% and improved overall system availability by minimizing downtime during maintenance due to its hot-swap capability.

Compared to similar safety controller modules in the market, the HIMA F6706 distinguishes itself through its combination of top-tier safety certification, robust environmental tolerance, and seamless compatibility with HIMA’s ecosystem. It offers faster processing speeds and higher diagnostic coverage than many alternatives, ensuring more reliable fault detection and quicker response times. The module’s design prioritizes ease of integration and maintenance, reducing installation and lifecycle costs for users.

HIMA F6706

When selecting the HIMA F6706, consider the following factors:

- Compatibility: Ensure it aligns with your existing HIMA safety system (e.g., HIMax or HIMatrix) to leverage full functionality and seamless communication.

- Environment: Evaluate the operational temperature, humidity, and vibration conditions to confirm the module’s suitability for your site.

- Safety Requirements: Verify that its SIL 3 certification meets the safety integrity needs of your application, especially for high-risk processes.

- Redundancy Needs: If continuous operation is critical, opt for a redundant configuration supported by the HIMA F6706 to avoid single points of failure.

- Installation: Follow electrostatic discharge (ESD) protection guidelines during handling and installation to prevent component damage.

- Configuration: Use HIMA’s approved software tools for programming to ensure compliance with safety standards and avoid configuration errors.

- Maintenance: Regularly update the module’s firmware to benefit from the latest safety enhancements and bug fixes, and perform periodic diagnostic tests to monitor its health.

- Safety Compliance: Always validate the system design and configuration against relevant safety standards (e.g., IEC 61508) with a qualified engineer to ensure proper functionality.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide