Description

1. Product Overview

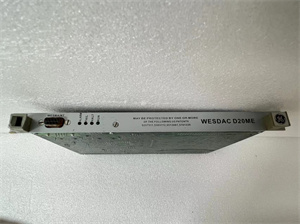

The Western D20M is likely a product from Western Products, a well – known company in the industrial control and automation field. While specific details can vary, based on common naming conventions in the industry, it could be a type of controller or a related device used for process control, such as temperature, pressure, or flow control.

2. Possible Product Parameters

General

- Power Supply: It may operate on a common industrial voltage, such as 24V DC or 110 – 240V AC. The voltage tolerance could be around ±10% to ensure stable operation under different power conditions.

- Operating Temperature Range: Typically, it might be designed to work within a range of – 20°C to 60°C. This wide temperature range allows it to be used in various industrial environments, from cold storage areas to hot manufacturing plants.

- Dimensions: It could have relatively compact dimensions, for example, around 150mm (length) x 100mm (width) x 50mm (height) to fit easily into control panels.

- Weight: Approximately 0.5 – 1 kg, which is light enough for easy installation and handling.

Inputs and Outputs

- Input Channels:

- If it’s a process controller, it may have multiple analog input channels. For example, it could support 2 – 4 analog inputs for measuring variables like temperature (using thermocouples or RTDs), pressure, or flow. The input signal range might be 0 – 10V, 4 – 20mA, etc.

- There could also be digital input channels, perhaps 4 – 8 in number, used for receiving binary signals from switches, sensors, or other control devices.

- Output Channels:

- Analog output channels, say 1 – 2, could be available for controlling actuators such as valves or variable – speed drives. The output signal range would be similar to the input, like 0 – 10V or 4 – 20mA.

- Digital output channels, around 2 – 4, can be used to control relays, contactors, or other binary – controlled devices.

Control Features

- Control Algorithm: It may use a proportional – integral – derivative (PID) control algorithm, which is widely used in industrial control for precise regulation of processes. The PID parameters can usually be adjusted to optimize the control performance for different applications.

- Setpoint Range: The setpoint (the desired value of the controlled variable) range would depend on the application. For temperature control, it could be from – 50°C to 500°C; for pressure control, it might be from 0 – 100 bar.

3. Advantages and Features

- Versatility: With multiple input and output channels and support for different signal types, the Western D20M can be used in a wide variety of industrial applications. It can handle different process variables, making it a flexible choice for system integrators.

- Precise Control: The use of a PID control algorithm allows for accurate regulation of the controlled variable. This helps in maintaining process stability and achieving high – quality output in industrial processes.

- Ease of Use: It may come with an intuitive user interface, such as a display and simple control buttons, making it easy for operators to set parameters, view process values, and make adjustments.

- Reliability: Built with high – quality components and designed to operate in harsh industrial environments, it offers reliable performance over a long period. The electrical isolation between input and output channels can also enhance its reliability by protecting against electrical interference.

4. Application Fields and Application Cases

- Application Fields

- Manufacturing: In manufacturing processes, it can be used to control the temperature of ovens, furnaces, or cooling systems. For example, in a plastic injection – molding process, it can regulate the temperature of the mold to ensure consistent product quality.

- Food and Beverage: In food processing, it can control the temperature and pressure in cooking, pasteurization, and fermentation processes. For instance, in a brewery, it can maintain the correct temperature during the fermentation of beer.

- HVAC (Heating, Ventilation, and Air Conditioning): It can be employed to control the temperature and humidity in commercial and industrial buildings. It can adjust the operation of heaters, coolers, and fans to maintain a comfortable and energy – efficient environment.

- Application Case

- In a bakery, the Western D20M is used to control the temperature of the ovens. Temperature sensors are connected to the analog input channels of the controller. The operator sets the desired baking temperature as the setpoint. The controller uses the PID algorithm to compare the measured temperature with the setpoint and adjusts the heating elements (connected to the output channels) accordingly. This ensures that the bread is baked at the optimal temperature, resulting in consistent quality and reduced waste.

5. Competitor Comparison

Compared to other similar controllers in the market, the Western D20M may have several advantages. Its combination of multiple input and output channels, precise control algorithm, and ease of use can be more attractive than some competitors. Some competing products may have limited input/output options or less – intuitive user interfaces. Additionally, the reliability and wide operating temperature range of the Western D20M can give it an edge in harsh industrial environments.

6. Selection Advice

- Application Requirements: Determine the specific requirements of your application, such as the number of input and output channels needed, the type of process variable to be controlled, and the required accuracy. Make sure the Western D20M can meet these requirements.

- Compatibility: Check if the controller is compatible with other components in your system, such as sensors, actuators, and communication networks.

- Budget: Consider your budget when selecting the controller. While the Western D20M offers high – quality performance, make sure it fits within your financial constraints.

- Technical Support: Look into the availability of technical support from the manufacturer. In case of any issues or for customization needs, good technical support can be crucial.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, sensors, and actuators are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, input/output signal ranges, and temperature limits. Regularly monitor the controller’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the controller to remove dust and debris. Check the integrity of the connections and replace any worn – out parts promptly.

If you need more detailed information about the Western D20M, it is recommended to contact the manufacturer or an authorized distributor. Shanxi Xinyeda International Trade Co., Ltd. may also be able to provide some assistance and related products. You can visit our website www.xydcontrol.com or contact us for more details.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide