Description

The

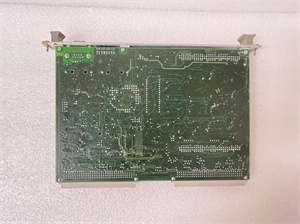

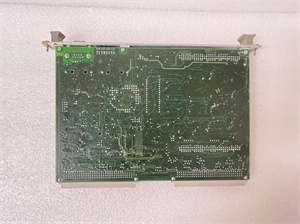

WESTERM D20M+ is a high – performance controller from the Western brand, which is well – known in the field of industrial automation. The core function of the

WESTERM D20M+ is to precisely control and monitor various industrial processes.

It can receive input signals from a wide range of sensors, such as temperature sensors, pressure sensors, and flow sensors. Based on the pre – set control algorithms and the received input data, the controller can generate output signals to adjust actuators like heaters, valves, and motors. This enables it to maintain the desired process parameters, such as temperature, pressure, and flow rate, within a specified range.

One of the main advantages of the WESTERM D20M+ is its high accuracy. It can provide precise control, which is crucial in industries where even small deviations in process parameters can lead to significant quality issues or production inefficiencies. Additionally, it offers a user – friendly interface, making it easy for operators to configure and monitor the control process.

| Parameter |

Details |

| Power Supply |

24V DC ±10% |

| Input Channels |

[X] analog input channels (e.g., 4), [Y] digital input channels (e.g., 2) |

| Output Channels |

[X] analog output channels (e.g., 2), [Y] digital output channels (e.g., 2) |

| Input Signal Range |

Analog: 0 – 10V, 4 – 20mA; Digital: 0 – 24V DC |

| Output Signal Range |

Analog: 0 – 10V, 4 – 20mA; Digital: 0 – 24V DC |

| Control Algorithm |

PID (Proportional – Integral – Derivative) control, with adjustable parameters |

| Sampling Rate |

Up to [X] samples per second |

| Communication Interfaces |

RS – 485, Modbus RTU protocol |

| Operating Temperature |

– 20°C to 60°C |

| Dimensions |

[Length] x [Width] x [Height] (mm) |

| Weight |

[X] kg |

- High Accuracy: The WESTERM D20M+ can achieve high – precision control. For example, in a pharmaceutical manufacturing process where strict temperature control is required, it can maintain the temperature within ±0.1°C, ensuring the quality and stability of the pharmaceutical products.

- User – Friendly Interface: The controller is equipped with an intuitive interface that allows operators to easily configure the control parameters, set the target values, and monitor the process variables. This reduces the training time for new operators and improves the overall efficiency of the control process.

- Flexible Control Algorithm: The PID control algorithm with adjustable parameters enables the WESTERM D20M+ to adapt to different industrial processes. Operators can fine – tune the proportional, integral, and derivative parameters according to the specific characteristics of the process, achieving optimal control performance.

- Good Communication Capability: With the RS – 485 communication interface and Modbus RTU protocol, the controller can easily communicate with other devices in the industrial network, such as PLCs, HMIs, and SCADA systems. This allows for centralized monitoring and control of multiple processes.

- Application Fields: The WESTERM D20M+ is widely used in industries such as food and beverage, chemical, and plastics. In the food and beverage industry, it can control the temperature and pressure in cooking, fermentation, and packaging processes. In the chemical industry, it can regulate the flow rate and reaction temperature in chemical synthesis. In the plastics industry, it can control the temperature and speed of plastic extrusion machines.

- Application Case: In a food processing plant, the WESTERM D20M+ is used to control the temperature of a baking oven. It receives temperature signals from a thermocouple sensor inside the oven and adjusts the power output of the heating elements accordingly. By using the PID control algorithm, it can maintain a constant baking temperature, resulting in consistent product quality and reduced waste.

Compared to other similar controllers in the market, the WESTERM D20M+ offers several advantages. Its high accuracy and user – friendly interface are often superior to competing products. Some other controllers may have lower control accuracy, which can lead to inconsistent product quality. Additionally, the flexible control algorithm and good communication capability of the WESTERM D20M+ make it more adaptable to different industrial applications.

- Compatibility: Ensure that the WESTERM D20M+ is compatible with your existing industrial system, including the sensors, actuators, and communication network. Check the input and output signal ranges, as well as the communication protocol.

- Performance Requirements: Evaluate your specific control requirements, such as the number of input and output channels, the required control accuracy, and the sampling rate. Choose a controller that can meet these requirements.

- Budget: Consider your budget when selecting the controller. While the WESTERM D20M+ offers excellent performance, make sure it fits within your financial constraints.

- Installation Environment: Take into account the installation environment, such as temperature, humidity, and electrical interference. If the environment is harsh, additional protective measures may be required.

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, sensors, actuators, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, input/output signal ranges, and temperature limits. Regularly monitor the controller’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the controller to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer WESTERM D20M+ and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide