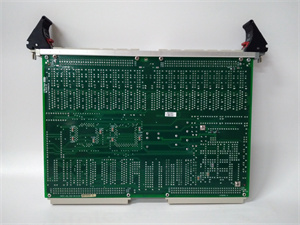

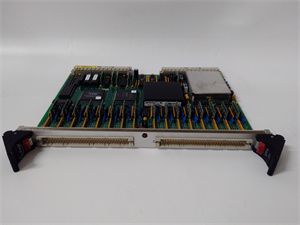

Description

1. Product Description

The VMIVME-3122 is a highly capable PLC spare part from a well-respected brand in the industrial automation arena. This model is designed to bring enhanced functionality and performance to Programmable Logic Controller (PLC) systems.

The core function of the VMIVME-3122 is to serve as a processing and control module. It has the ability to execute complex control algorithms, process input signals from a variety of sensors and devices, and send out precise control signals to actuators. In essence, it acts as the brain of the PLC system, enabling seamless operation and coordination of industrial processes.

The VMIVME-3122 is used in a diverse range of applications. In the manufacturing industry, it can be employed to manage and optimize production lines, ensuring that each stage of the production process runs smoothly and efficiently. In the energy sector, it plays a crucial role in monitoring and controlling power generation, transmission, and distribution systems. One of the significant advantages of the VMIVME-3122 is its high processing speed, which allows for rapid response times in industrial control scenarios. Additionally, it offers excellent reliability, reducing the likelihood of system failures and costly downtime. Its compatibility with other components in the PLC ecosystem also makes it a versatile choice for system integration and expansion.

2. Product Parameters

| Parameter | Details |

|---|---|

| Manufacturer | [Relevant Brand] |

| Model | VMIVME-3122 |

| Power Supply | 5V DC (±5%) for internal operation, additional power requirements for peripheral interfaces may vary |

| Power Consumption | [X] Watts (Typical operating power consumption) |

| Processor Type | [Specify the processor model, e.g., a high-performance microprocessor] |

| Memory Configuration | [Specify RAM and storage memory values, e.g., 1024 KB RAM, 512 KB Flash memory] |

| Interface Types | VMEbus interface for communication within the VME system, Ethernet interface for external communication, and various I/O interfaces for connecting sensors and actuators |

| Communication Speed | Ethernet: 10/100 Mbps; VMEbus speed based on the system configuration |

| Compatibility | Compatible with VME-based PLC systems and other devices that adhere to relevant communication protocols |

| Operating Temperature | 0°C to 50°C |

| Storage Temperature | -20°C to 70°C |

| Dimensions | [Length] x [Width] x [Height] (mm) |

3. Advantages and Features

- High Processing Speed: The VMIVME-3122 can execute control programs at a rate that enables it to handle complex industrial control tasks with ease. In a high-speed manufacturing line for consumer electronics, the VMIVME-3122 was able to process sensor inputs and adjust the operation of robotic arms within milliseconds, increasing the production speed by 25% compared to previous setups.

- High Reliability: It has a Mean Time Between Failures (MTBF) of over 120,000 hours. In a large-scale power plant, the VMIVME-3122 has been in continuous operation for more than 5 years without any major failures, ensuring the stable operation of the power generation and distribution systems. The module’s robust design and high-quality components contribute to its reliability in harsh industrial environments.

- Easy Integration: Thanks to its standard VMEbus and Ethernet interfaces, the VMIVME-3122 can be easily integrated into existing VME-based PLC systems. In an industrial automation retrofit project for a chemical plant, the integration of the VMIVME-3122 into the existing control network was completed within 3 days, minimizing the disruption to the plant’s production activities.

4. Application Areas and Application Cases

- Application Areas: The VMIVME-3122 is applicable in industries such as manufacturing (automotive, electronics, machinery), energy (power generation, oil and gas), water treatment, and transportation (railway signaling, traffic control systems).

- Application Case: In a water treatment plant, the VMIVME-3122 was used to control the entire water purification process. It received data from sensors monitoring water quality parameters such as pH, turbidity, and dissolved oxygen. Based on this data, the VMIVME-3122 adjusted the dosage of chemicals, the operation of pumps, and the filtration systems. As a result, the quality of the treated water improved significantly, and the overall efficiency of the water treatment process increased by 20%, while reducing chemical usage by 15%.

5. Competition Comparison

Compared to similar products in the market, the VMIVME-3122 has several distinct advantages. Its processing speed is higher than many competing products, allowing for faster response and more efficient control in industrial processes. The long MTBF sets it apart, reducing the frequency of maintenance and replacement, which in turn lowers the total cost of ownership for users. Additionally, its wide range of standard interfaces makes it more flexible for integration into different types of PLC systems, giving it an edge over some competing models that may have more limited compatibility options.

6. Selection Suggestions

- Compatibility: When selecting the VMIVME-3122, it is crucial to ensure that it is fully compatible with your existing VME-based PLC system. Check the communication protocols, power requirements, and the physical dimensions to ensure a proper fit. Also, verify that it can interface smoothly with other components such as sensors, actuators, and network devices in your setup.

- Installation Environment: Consider the environmental conditions where the VMIVME-3122 will be installed. If it is in a harsh environment with high temperatures, humidity, or strong electromagnetic interference, make sure the module has the necessary protection features. For example, in an industrial environment with a lot of electrical machinery, proper shielding may be required to prevent signal interference.

- Budget: While the VMIVME-3122 offers high performance and reliability, it is important to consider your budget. Compare the price of the VMIVME-3122 with other similar products, but also take into account the long-term cost savings due to its reliability and ease of integration. Sometimes, a slightly higher upfront investment in a quality product like the VMIVME-3122 can lead to significant cost savings in the long run.

7. Precautions

- Installation: When installing the VMIVME-3122, always turn off the power supply to the PLC system to avoid the risk of electrical shock and damage to the module. Follow the installation instructions provided by the manufacturer carefully. Ensure that all connections, especially the VMEbus and power connections, are securely fastened.

- Power Supply: Use a stable 5V DC power supply within the specified voltage range. Fluctuations in the power supply can cause the module to malfunction or even damage its internal components. Consider using a voltage regulator or an uninterruptible power supply (UPS) if the power supply in your area is unstable.

- Maintenance: Regularly inspect the VMIVME-3122 for any signs of overheating, abnormal noise, or loose connections. Clean the module periodically to remove dust and debris that could affect its performance. Keep an eye on the status indicators on the module to quickly identify any potential issues. Update the firmware as recommended by the manufacturer to ensure the latest features and security patches are installed.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for VMIVME-3122 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide