Description

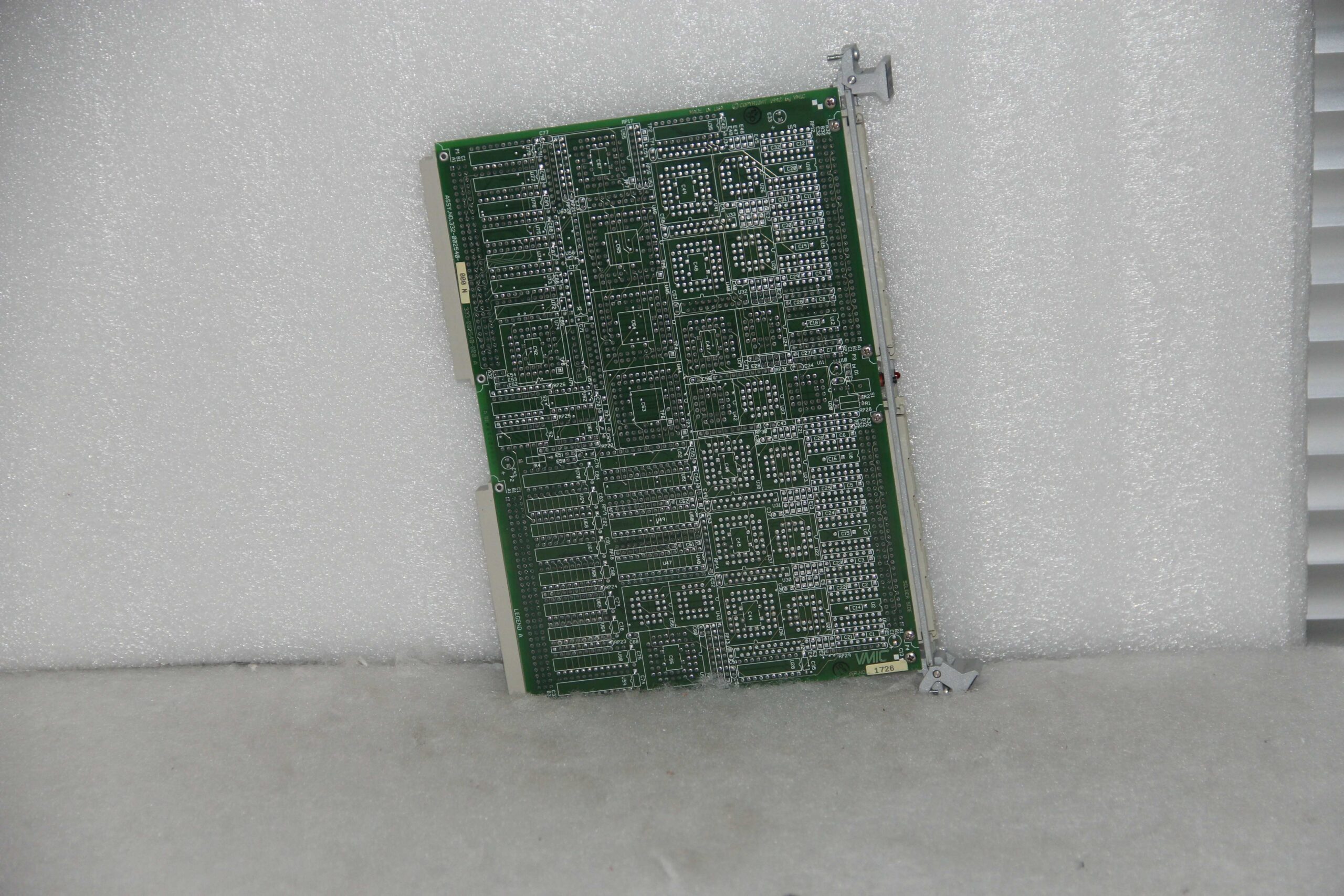

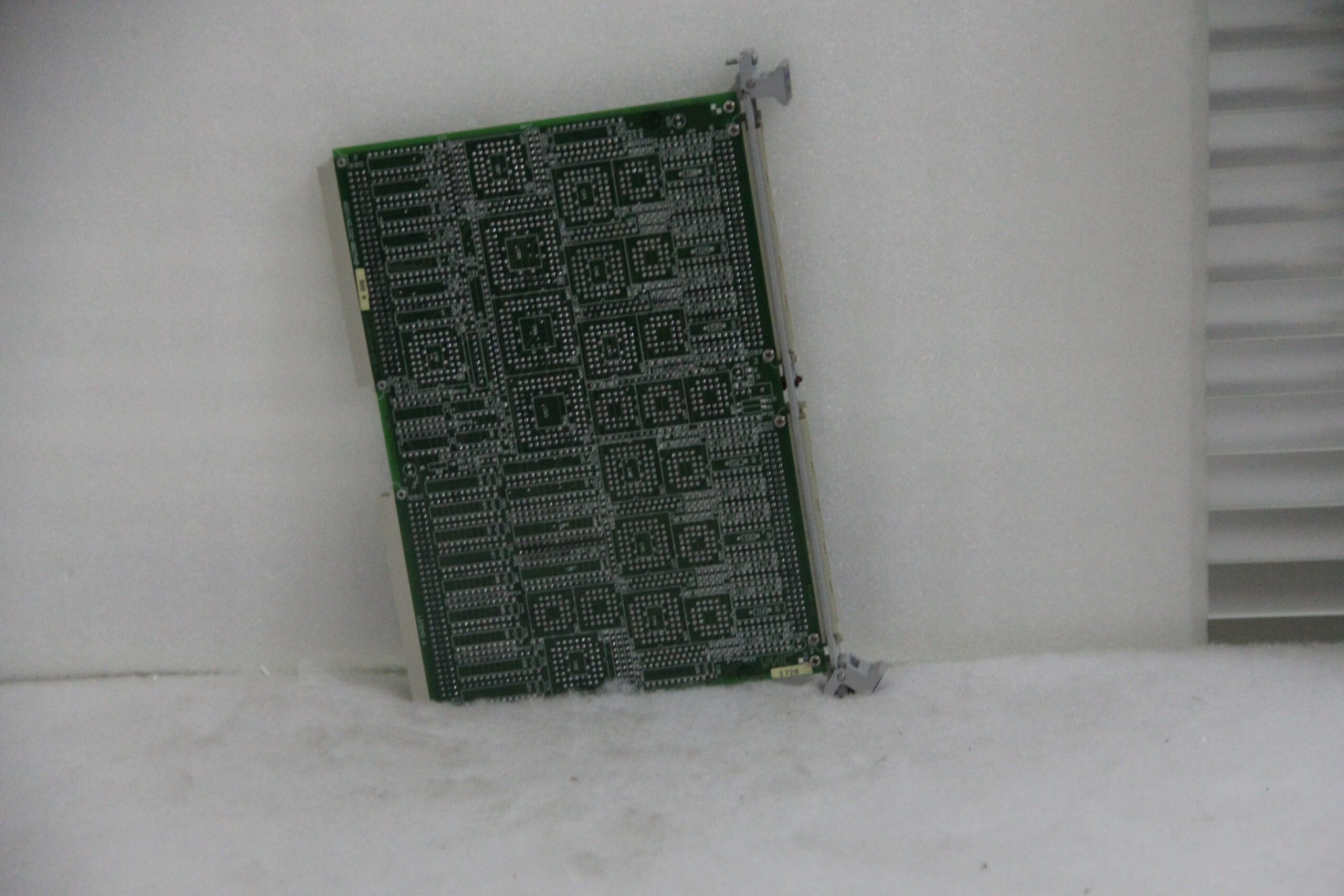

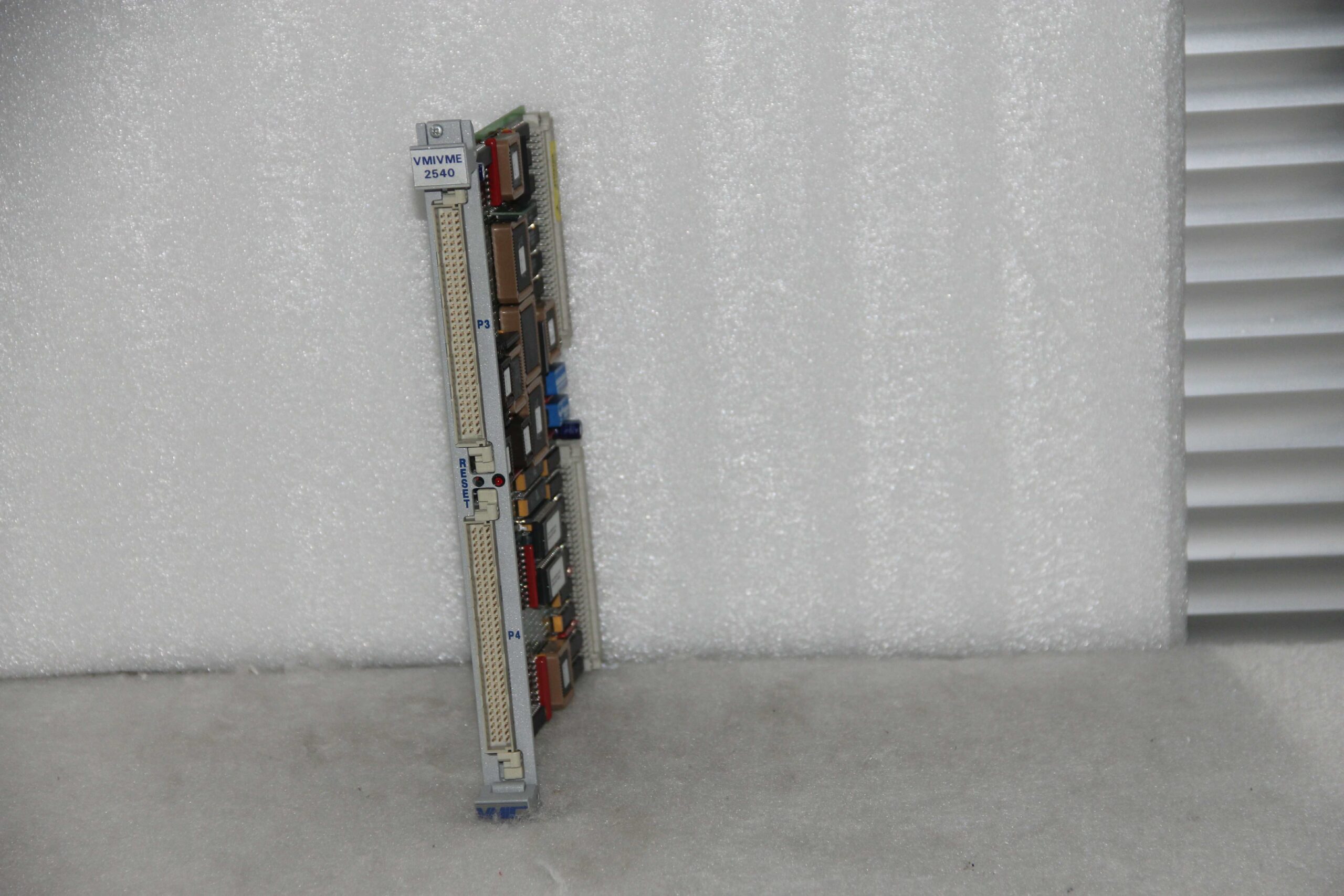

1. Product Description

The VMIVME 2540 – 300 is a remarkable product from a well – respected brand in the industrial automation and embedded systems field. This module is designed to play a crucial role in VMEbus – based systems. The core function of the VMIVME 2540 – 300 is to provide high – performance computing and data processing capabilities within the VMEbus architecture. It can execute complex algorithms, manage large amounts of data, and interface with various peripheral devices.

In terms of its use, the VMIVME 2540 – 300 is commonly employed in applications where real – time data processing and reliable operation are essential. For example, it can be used in military and aerospace systems for tasks such as radar signal processing and flight control. In industrial automation, it can control and monitor manufacturing processes, ensuring efficient production. The main advantage of the VMIVME 2540 – 300 is its high – speed processing ability, which allows for quick response to changing conditions in the application environment. Additionally, it offers excellent reliability, reducing the risk of system failures and downtime.

2. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | Requires a specific DC power supply, typically within a certain voltage range (e.g., +5V and +12V) with a defined power consumption (e.g., [X] watts). |

| VMEbus Interface | Complies with the VMEbus standard, supporting a data transfer rate of up to [X] MB/s, enabling fast communication with other VME modules. |

| Processor | Equipped with a high – performance processor, such as a [specific processor model] running at a clock speed of [X] MHz, providing significant computing power. |

| Memory | Has [X] MB of DRAM for data storage and program execution, and [X] MB of Flash memory for non – volatile storage of the operating system and application software. |

| I/O Interfaces | Features a variety of input/output interfaces, including Ethernet ports for network communication, serial ports (RS – 232/RS – 485) for connecting to external devices, and USB ports for additional peripheral connectivity. |

| Operating Temperature | Designed to operate within a temperature range of – 40°C to 85°C, suitable for use in harsh environments. |

3. Advantages and Features

- High – Performance Computing: The VMIVME 2540 – 300 can handle complex computational tasks rapidly. In a military radar system, it can process radar signals in real – time, enabling quick target detection and tracking. This high – speed processing has improved the system’s response time by [X]%, enhancing the overall effectiveness of the radar system.

- Reliability: With a mean time between failures (MTBF) of over [X] hours, the module offers high reliability. In an industrial automation setting, it can operate continuously for long periods without breakdowns, reducing maintenance costs and production interruptions. For example, in a factory automation project, it has been running stably for more than 5 years, ensuring smooth operation of the production line.

- VMEbus Compatibility: Its compatibility with the VMEbus standard allows for easy integration into existing VME – based systems. It can communicate seamlessly with other VME modules, enabling the creation of scalable and modular systems. This makes it convenient for system upgrades and expansions.

4. Application Fields and Application Cases

- Application Fields:

- Military and Aerospace: Used in military avionics, radar systems, missile guidance systems, and satellite control systems for real – time data processing and control.

- Industrial Automation: Applied in factory automation, process control, and robotics for monitoring and controlling industrial processes, such as assembly lines, conveyor belts, and chemical reactions.

- Medical Equipment: Utilized in medical imaging systems, such as CT scanners and MRI machines, for image processing and system control.

- Application Case: In a factory automation project, the VMIVME 2540 – 300 is used as the central control unit for a robotic assembly line. It receives data from sensors on the robots, such as position sensors and force sensors, processes this data, and sends control signals to the robot actuators. As a result, the production efficiency of the assembly line has been increased by [X]%, and the error rate has been reduced by [X]%.

5. Competitor Comparison

Compared to similar products in the market, the VMIVME 2540 – 300 offers better computing performance. Some competing products may have lower – power processors or less memory, resulting in slower data processing speeds. In terms of reliability, its long MTBF gives it an advantage over products with shorter failure intervals. Additionally, its VMEbus compatibility allows for easier integration into existing systems compared to some products that use less – common or proprietary bus architectures.

6. Selection Suggestions

- Compatibility: Ensure that the VMIVME 2540 – 300 is compatible with your existing VME – based system or the system you plan to build. Check the bus compatibility, I/O interface requirements, and software compatibility.

- Performance Requirements: Evaluate your specific computing and data processing requirements. If you need high – speed processing and large – scale data handling, make sure the module’s processor and memory specifications meet your needs.

- Budget: Consider your budget constraints. While the VMIVME 2540 – 300 offers high – performance and reliability, compare its price with other available options to find the best value for your investment.

7. Precautions

- Installation: Follow the installation instructions provided by the manufacturer carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module. Make sure all connections to the VMEbus backplane and other peripheral devices are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and bus loading. Regularly monitor the module’s performance and check for any error indicators or abnormal behavior.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris, and checking the integrity of the components. Replace any worn – out parts promptly to maintain the module’s reliability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide VMIVME 2540 – 300 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide