Description

The following is a detailed product description of

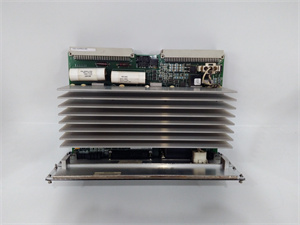

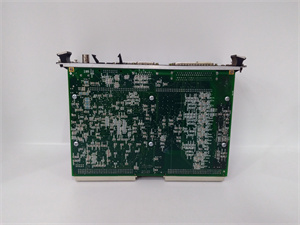

IS215VPROH2B:

IS215VPROH2B, developed by General Electric, is an emergency turbine protection board of the Mark VI series124. It plays a vital role in safeguarding the safe and stable operation of turbines4. The IS215VPROH2B, along with associated terminal boards TPRO and TREG, forms an independent emergency overspeed protection system125. It is equipped with three analog current inputs and nine thermocouple inputs, which are mainly used for exhaust over-temperature protection in gas turbines157. In addition, it has an Ethernet connection for IONet communication with the control module15.

- Power Supply Voltage: 125 V DC24

- Number of Inputs: 324

- Number of Outputs: 624

- Operating Temperature: -30 to 65 ºC24

- Board Size: 33.0 cm high x 17.8 cm24

- Ethernet Interface: Thinwire 10Base26

- Memory: 16 MB of DRAM6

- Processor Type: Pentium6

- Baud Rate: 192006

- High Redundancy: The protection system consists of triple redundant VPRO boards, which ensures high reliability. Even if one board fails, the other two can still guarantee the normal operation of the protection system125.

- Comprehensive Protection Functions: It provides emergency overspeed protection, emergency stop function, and backup synchronization check protection. For example, it can accurately monitor the turbine speed through six passive magnetic speed sensors and take timely protection measures when the speed exceeds the limit125.

- Wide Temperature Adaptability: With an operating temperature range of -30 to 65 ºC, it can work stably in various harsh industrial environments, from cold regions to high-temperature workshops4.

- Application Areas: It is mainly applicable to the field of power generation, such as gas turbines and steam turbines in power plants. It can also be used in some large industrial production lines that require turbine drive, such as the petrochemical industry and the metallurgical industry.

- Application Case: In a large power plant, the IS215VPROH2B is used in the gas turbine control system. Once, due to a sudden failure of the gas supply system, the turbine speed began to rise rapidly. The IS215VPROH2B quickly detected this abnormal situation through the speed sensor, and then sent a trip signal through the output channel to quickly stop the turbine, effectively avoiding equipment damage and potential safety accidents.

Compared with some similar products in the market, IS215VPROH2B has more comprehensive protection functions. It not only focuses on overspeed protection but also provides backup synchronization check and other functions. In terms of temperature adaptability, its wide operating temperature range enables it to have more advantages in different environments. In addition, the high redundancy design of the triple VPRO boards makes its reliability significantly higher than some products with single or dual redundancy.

- Compatibility: Ensure that the IS215VPROH2B is compatible with your existing turbine control system, including checking the communication interface, signal type and other aspects.

- Installation Environment: Consider the actual installation space and environmental conditions. Make sure that the temperature, humidity and dust conditions of the installation location are within the operating range of the board.

- Budget: Although the IS215VPROH2B provides high performance and reliability, it is also necessary to consider the cost. Evaluate whether its price is within your budget range in combination with the actual needs of the project.

- Installation: When installing, turn off the VME processor I/O rack first. After manually positioning the edge connectors, slide the VPRO board into place and tighten the top and bottom captive screws on the front panel2.

- Operation: Regularly check the status of the front panel LEDs. The RUN status is a flashing green light, the FAIL status is a steady red light, and if there is a diagnostic alarm, the STATUS LED will show a constant orange light15.

- Maintenance: Perform regular maintenance and inspection to ensure that the board is free of dust and corrosion. It is recommended to update the firmware of the VPRO board in a timely manner to ensure its performance and stability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IS215VPROH2B and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide