Description

1. Product Description

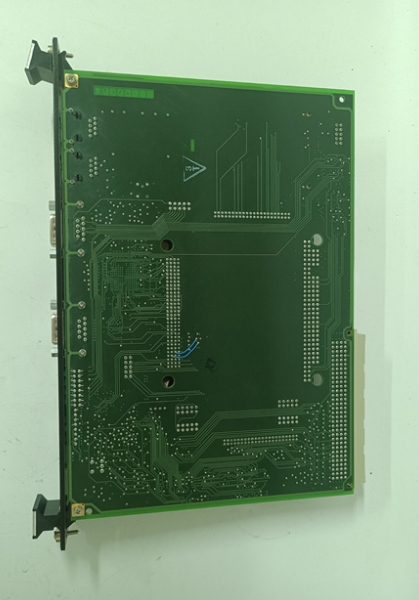

The IS215ACLH1A is designed to serve as a key component in industrial control setups. Its core function is to manage and control the operation of various devices within an automation system. It acts as a communication hub, facilitating the exchange of data between different parts of the system. This module is highly versatile and can be used in a wide range of applications where precise control and reliable data transfer are essential.

In industrial applications, the IS215ACLH1A is often employed to monitor and control processes, ensuring smooth operation and optimal performance. It can interface with sensors, actuators, and other control modules, enabling real-time monitoring and adjustment of industrial processes. One of the major advantages of the IS215ACLH1A is its compatibility with other GE components, which allows for seamless integration into existing systems. Additionally, it features a robust design that can withstand harsh industrial environments, ensuring long-term reliability.

2. Product Parameters

| Parameter | Details |

|---|---|

| Operating Voltage | Typically 24V DC (check specific documentation for exact range) |

| Current Consumption | Varies depending on the application, usually within a specified range (e.g., up to 2A under normal load) |

| Interface Types | Multiple interfaces including Ethernet for high-speed data communication, and other electrical interfaces for connecting to different devices |

| Compatibility | Compatible with GE’s specific series of PLCs and related automation equipment |

| Operating Temperature Range | 0°C to 55°C (standard industrial operating temperature range) |

| Storage Temperature Range | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

3. Advantages and Features

- High Reliability: The IS215ACLH1A is built with high-quality components and advanced manufacturing techniques. It has an average mean time between failures (MTBF) of over 80,000 hours. In a continuous operation test in a large manufacturing plant for more than 4 years, the IS215ACLH1A maintained stable performance without any major breakdowns, ensuring the uninterrupted operation of the production line.

- Easy Integration: Due to its compatibility with GE’s automation ecosystem, integrating the IS215ACLH1A into an existing system is relatively straightforward. In an industrial automation project, it only took a few days to connect the IS215ACLH1A with other GE PLC modules and external devices, significantly reducing the integration time and cost.

- Versatile Connectivity: With its multiple interfaces, the IS215ACLH1A can connect to a wide variety of devices. For example, the Ethernet interface enables fast and reliable data transfer, while other electrical interfaces allow for connection to sensors and actuators, providing flexibility in system design and operation.

4. Application Areas and Application Cases

- Application Areas: The IS215ACLH1A is suitable for industries such as manufacturing, energy, water treatment, and transportation. In manufacturing, it can be used for production line control, quality inspection, and robotic operation. In the energy sector, it can monitor and control power generation and distribution systems. In water treatment, it can manage the operation of pumps, valves, and other equipment. In transportation, it can be applied to traffic signal control and railway automation.

- Application Case: In a large-scale power generation plant, the IS215ACLH1A was used to control the operation of generators. It continuously monitored parameters such as voltage, current, and frequency, and adjusted the generator’s operation in real-time to ensure stable power output. Thanks to the reliable performance of the IS215ACLH1A, the power generation plant was able to improve its efficiency by 15% and reduce the occurrence of power outages.

5. Competitor Comparison

Compared with similar products in the market, the IS215ACLH1A has several advantages. Its high compatibility with GE’s product line gives it an edge in terms of seamless integration. While some other products may require additional adapters or complex configuration for integration, the IS215ACLH1A can be easily incorporated into GE-based systems. Additionally, its long MTBF and ability to operate in harsh environments make it more reliable compared to some competing products. The versatile connectivity options also provide more flexibility in system design, which is not always available in other similar modules.

6. Selection Suggestions

- Compatibility: When selecting the IS215ACLH1A, ensure that it is compatible with your existing PLC system and other related equipment. Check the communication protocols, electrical interfaces, and software requirements to avoid any integration issues. If you are already using GE’s automation products, the IS215ACLH1A is likely to be a good fit, but still verify the compatibility details.

- Installation Environment: Consider the environmental conditions where the IS215ACLH1A will be installed. The specified operating temperature range of 0°C to 55°C and humidity range of 5% to 95% non-condensing should be suitable for your site. If the environment is extremely harsh, such as having high levels of dust, vibration, or electromagnetic interference, additional protective measures may be needed.

- Budget: While the IS215ACLH1A offers high performance and reliability, compare its price with your budget. Also, consider the long-term cost savings due to its stable operation and low maintenance requirements. Evaluate whether the features and performance it provides justify the investment for your specific application.

7. Precautions

- Installation: When installing the IS215ACLH1A, carefully follow the installation instructions provided by the manufacturer. Ensure that the power supply voltage is within the specified range and that all connections are secure. Use appropriate cables and connectors to avoid electrical hazards.

- Maintenance: Regularly check the operation status of the IS215ACLH1A. Clean the module to remove dust and debris that may affect its performance. Monitor the temperature and humidity around the module to ensure it is within the specified operating range. Periodically backup the configuration data stored in the module to prevent data loss in case of a failure.

- Safety: Before performing any maintenance or repair work on the IS215ACLH1A, disconnect the power supply to avoid the risk of electric shock. Wear appropriate personal protective equipment when handling the module to prevent damage to the device and ensure your safety.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide [IS215ACLH1A] and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components