Description

The

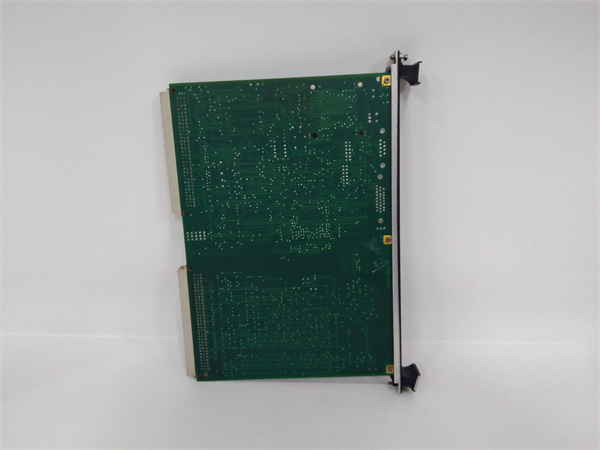

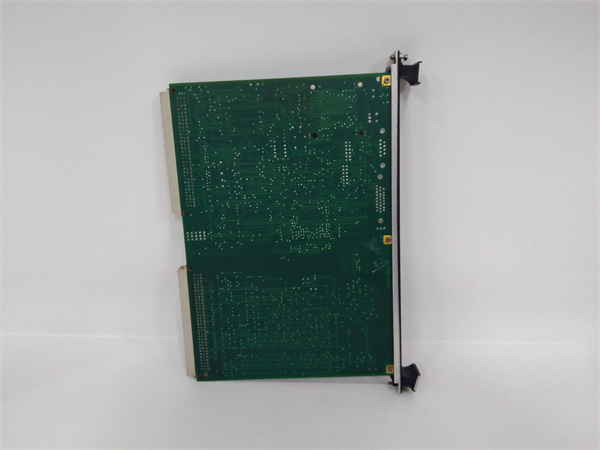

IS200VTCCH1CBB serves as a critical interface for temperature measurement in GE’s Mark VI turbine control systems. It accepts 24 thermocouple inputs (grounded/ungrounded) with linearization support via Mark VI software, ensuring accurate temperature data for turbine efficiency and safety. The board features dual cold-junction compensation, high-frequency noise suppression, and a compact design (2.1 × 18.8 × 26.2 cm) with DIN-rail mounting. Key components include an Xilinx Spartan XCS30 FPGA, dual-port SRAM, and DSP for real-time signal processing. Compatible with TBTCH1C (simplex) or TBTCH1B (triple modular redundant, TMR) terminal boards, it supports simplex/TMR configurations for redundant control systems.

| Parameter |

Specification |

| Brand |

GE Fanuc |

| Series |

Mark VI (Speedtronic Turbine Control) |

| Type |

Thermocouple Input Terminal Board |

| Input Signals |

24 thermocouples (E/J/K/S/T) or mV (-8 to +45 mV) |

| Compatibility |

GE Mark VI systems, TBTCH1C/TBTCH1B boards |

| Dimensions |

2.1 cm (W) × 18.8 cm (H) × 26.2 cm (D) |

| Weight |

0.3 kg (0.66 lbs) |

| Power Supply |

24VDC (via Mark VI chassis) |

| Signal Isolation |

Galvanic isolation (grouped per terminal block) |

| Cable Length |

Up to 300 m (984 ft) |

| Temperature Range |

-40°C to +85°C (operating); -55°C to +125°C (storage) |

| Mounting |

DIN rail (Mark VI chassis integration) |

| Protection |

Conformal coating (IP20), overvoltage/current protection |

IS200VTCCH1CBB

- High Precision: Cold-junction compensation and linearization ensure ±0.1% temperature accuracy.

- Redundancy Support: TMR capability via TBTCH1B board for fault-tolerant systems (e.g., offshore turbines).

- Harsh Environment Resilience: Conformal coating resists moisture, dust, and vibration (IEC 60068-2-6 vibration test compliance).

- Scalability: Supports up to 24 thermocouples with 450 Ω max cable resistance for distributed sensor networks.

- Diagnostics: Automatic input validation; signals outside hardware limits are quarantined (GEH-6421 manual compliance).

- Industry: Power generation (gas/steam turbines), oil & gas (refineries), manufacturing (rotating machinery).

- Case Study: A U.S. power plant used IS200VTCCH1CBB in a TMR configuration for a 700MW steam turbine. The board’s 24-channel temperature monitoring detected a 120°C hot spot in a bearing during startup, triggering a proactive shutdown. This prevented $1.5M in repair costs and 48 hours of downtime.

Compared to standard thermocouple input modules:

- Channel Density: 24 inputs (vs. 12–16 in most alternatives).

- Redundancy Flexibility: Native TMR support (no external adapters).

- Signal Range: Wider mV span (-8 mV to +45 mV vs. typical 0–20 mV).

- Environmental Rating: Conformal coating standard (vs. optional in 竞品).

IS200VTCCH1CBB

- System Type: Use with GE Mark VI systems (Frame 5/6/7 turbines) requiring temperature monitoring.

- Redundancy: Pair with TBTCH1B for TMR systems (critical applications like nuclear backup power).

- Environment: Select conformal coating for coastal/moist environments; derate for >50°C ambient.

- Expansion: Combine with IS215VCMIH1B (communication module) for full Mark VI integration.

- Installation:

- Follow ESD protocols (anti-static gloves, grounded workspace).

- Torque terminal screws to 0.5–0.7 N·m; avoid loose connections.

- Maintenance:

- Inspect capacitors for swelling every 3 years (expected lifespan: 10 years).

- Verify cold-junction accuracy annually (±0.5°C tolerance).

- Safety:

- Disconnect power before servicing (24VDC isolation required).

- Avoid exposure to conductive dust; IP20-rated (indoor use only).

声明Shanxi Xinyeda International Trade Co., Ltd. specializes in

IS200VTCCH1CBB and GE Mark VI spare parts. Our certified modules undergo full functional testing (OEM system validation) and come with a 2-year warranty. Contact us for customized solutions, technical support, or visit

www.xydcontrol.com for pricing.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide