Description

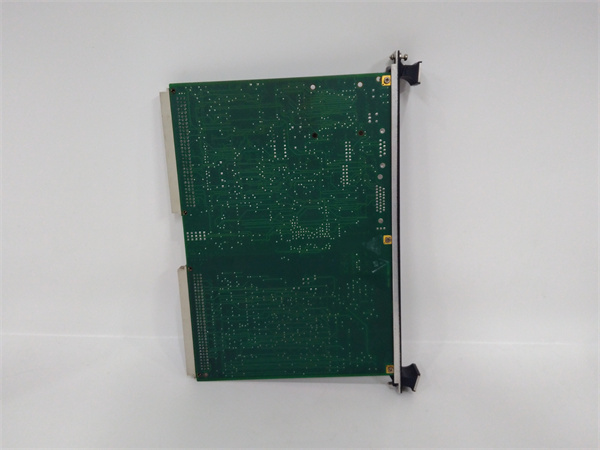

IS200VTCCH1C is a thermocouple input board of the GE Mark VI series

245. The following is an introduction to it:

- Manufacturer2: General Electric

- Product Type2: Thermocouple input board used in the Mark VI system for gas and steam turbine management.

- Thermocouple Input Types: Accepts 24 thermocouple inputs of type E, J, K, S, or T, as well as mV inputs in the range of -8 mV to +45 mV.

- A/D Converter: 16-bit resolution

- Cold Junction Compensation: Two cold junction references are used for each connector. The cold junction accuracy is 2 °F.

- Sampling Frequency: All inputs are sampled at 120 times per second.

- Cable Resistance: The maximum two-way cable resistance is 450, and the thermocouples can be located up to 300 m (984 ft) from the turbine control cabinet.

- High Channel Capacity: With 24 input channels, it can connect to a large number of thermocouples simultaneously, which is suitable for monitoring the temperature of multiple points in complex industrial equipment.

- Wide Thermocouple Compatibility: Supports multiple common thermocouple types, offering great flexibility in temperature measurement and meeting different application requirements.

- Accurate Cold Junction Compensation: Performs accurate cold junction compensation to ensure the accuracy of temperature measurement results.

- Built-in Diagnostic Function: The front panel is equipped with three LED components, namely “RUN” (green), “FAIL” (red), and “STATUS” (orange), which can visually display the operating status of the board and help with quick troubleshooting.

- Power Generation Industry: It is mainly used in gas turbines and steam turbines in power plants to monitor the temperature of various parts of the turbines, such as the inlet and outlet of the combustion chamber and the bearing temperature, so as to ensure the safe and efficient operation of the turbines.

- Petrochemical Industry: In petrochemical production equipment, such as cracking furnaces and reactors, the IS200VTCCH1C can be used to monitor the temperature of the equipment to prevent overheating and other abnormal conditions, ensuring the stability of the production process and the safety of the equipment.

- Metallurgical Industry: In the metallurgical process, for example, in the smelting furnace and rolling mill equipment, this board can be used to monitor the temperature to help control the process parameters and ensure the quality of the metal products.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IS200VTCCH1C and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide