Description

The

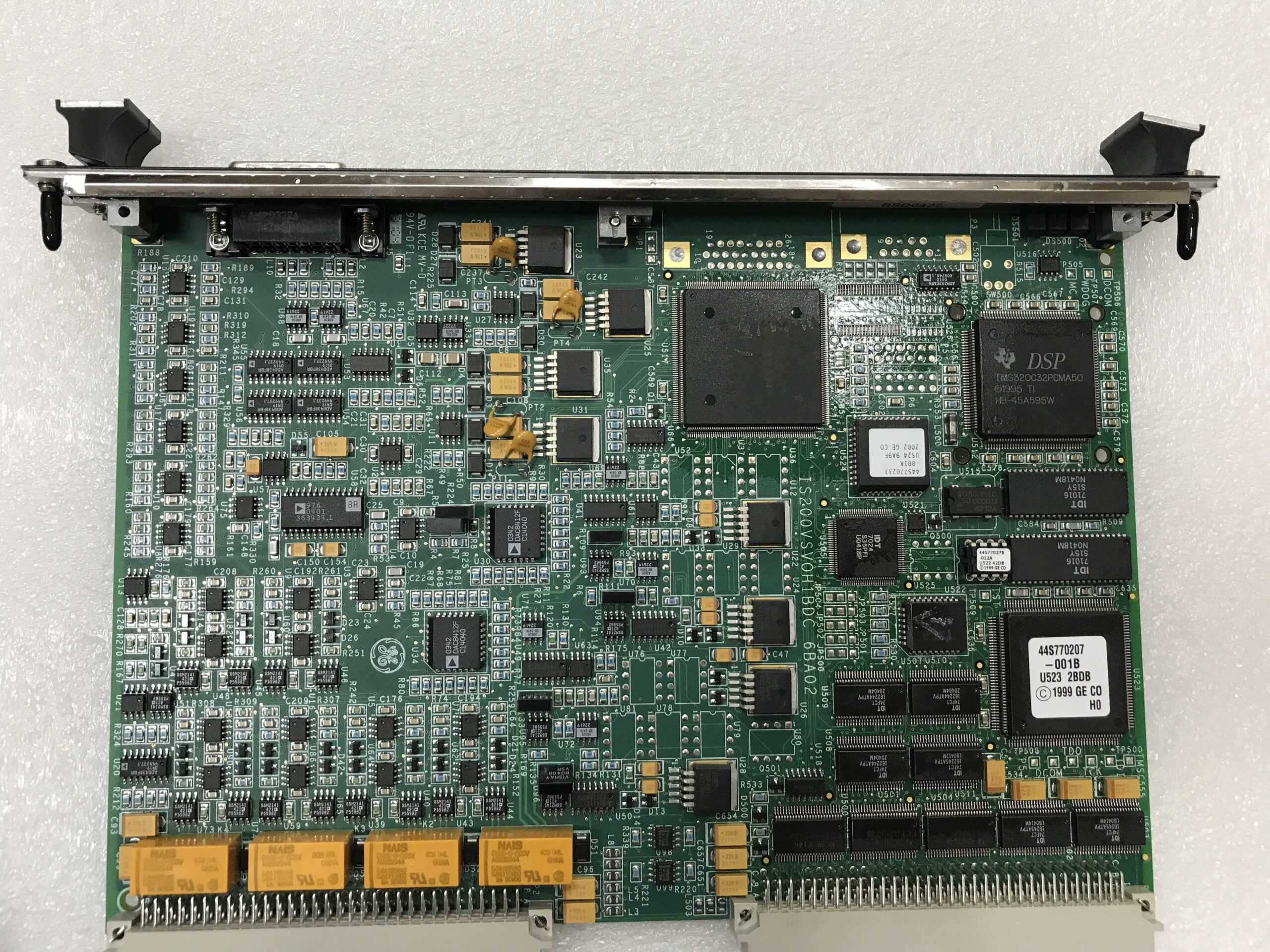

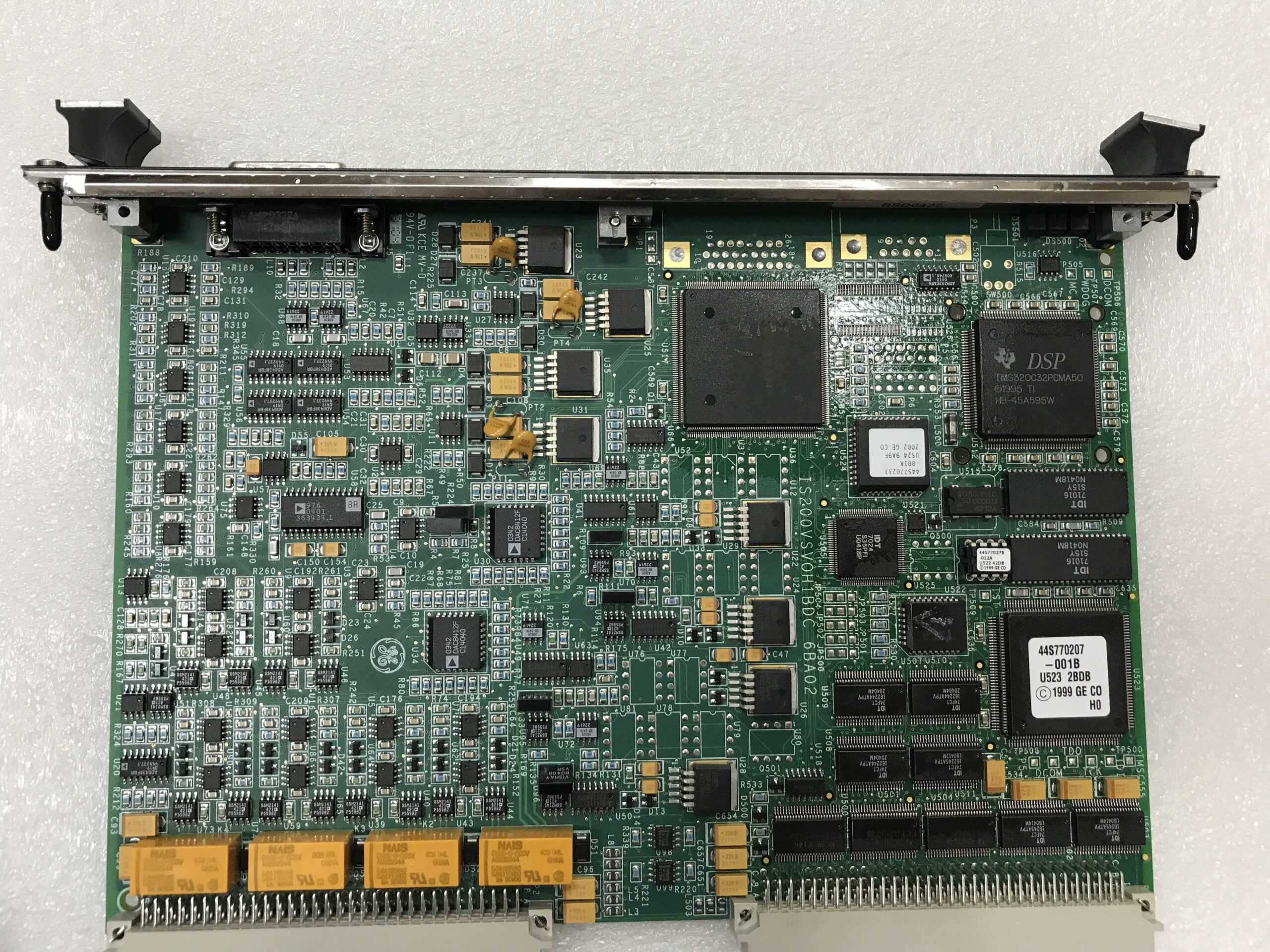

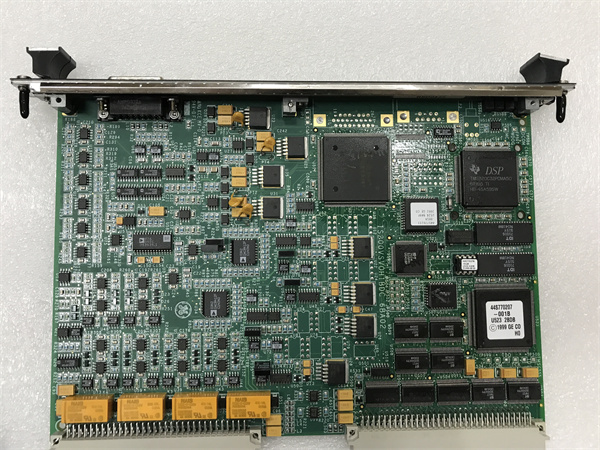

IS200VSVOH1BED is a notable product from General Electric, a well – known brand in the industrial automation domain. This module is designed to play a crucial role in industrial control systems, especially those based on GE’s advanced control platforms. The core function of the

IS200VSVOH1BED is to handle valve control and monitoring tasks. It can precisely control the opening and closing of valves, ensuring accurate regulation of fluid flow, pressure, and other process parameters in industrial processes.

In practical applications, the IS200VSVOH1BED is widely used in power generation plants, chemical processing facilities, and oil and gas refineries. For power plants, it can control the steam valves to optimize power generation efficiency. In chemical plants, it helps maintain the right chemical reactions by controlling the flow of reactants. The main advantage of the IS200VSVOH1BED is its high – precision control, which can significantly improve the quality and efficiency of industrial processes. Additionally, it offers excellent reliability, reducing the risk of valve malfunctions and production disruptions.

| Parameter |

Details |

| Power Supply |

Operates on 24V DC with a tolerance of ±[X]% (the specific tolerance can be found in the detailed documentation). |

| Input/Output Channels |

Has a specific number of digital and analog input/output channels. Digital channels are used for receiving and sending on/off signals, while analog channels can handle continuous signals related to valve position, pressure, etc. |

| Communication Interfaces |

Supports Ethernet and some proprietary GE communication protocols for seamless integration with other components in the control system. |

| Operating Temperature Range |

Designed to operate within a temperature range of – 20°C to 60°C, suitable for various industrial environments. |

| Valve Control Range |

Can control valves within a certain range of opening and closing degrees, with a high level of precision (e.g., ±[X]%). |

- High – Precision Control: The IS200VSVOH1BED can achieve extremely precise valve control. In a chemical processing plant, it can control the flow of a reactant with an accuracy of ±[X]%, ensuring the stability and quality of the chemical reaction. This high – precision control has increased the product yield by [X]% compared to previous control methods.

- Reliability: With a long mean time between failures (MTBF) of over [X] hours, the module offers high reliability. In an oil refinery, it has been operating continuously for more than [X] years without major failures, reducing maintenance costs and production downtime.

- Easy Integration: It is fully compatible with other modules in the GE control system ecosystem. This allows for easy integration into existing or new control systems, saving time and effort in system setup and configuration.

- Application Fields:

- Power Generation: Used in thermal, hydro, and gas – fired power plants to control steam valves, cooling water valves, and other critical valves.

- Chemical Processing: Applied in chemical plants to regulate the flow of reactants, products, and solvents in chemical reactions.

- Oil and Gas: Utilized in oil refineries, natural gas processing plants, and pipelines to control valves for fluid transportation and processing.

- Application Case: In a power generation plant, the IS200VSVOH1BED is used to control the steam valves of a turbine. It continuously monitors the steam pressure and flow rate and adjusts the valve opening accordingly. As a result, the power generation efficiency has been increased by [X]%, and the wear and tear of the turbine components have been reduced by [X]%.

Compared to similar valve control modules in the market, the IS200VSVOH1BED offers higher precision in valve control. Some competing products may have larger control errors, leading to less stable industrial processes. In terms of reliability, its long MTBF gives it an advantage over products with shorter failure intervals. Additionally, its easy integration with GE control systems makes it a more convenient choice for users who already have a GE – based control infrastructure.

- Compatibility: Ensure that the IS200VSVOH1BED is compatible with your existing control system, including communication protocols, power supply requirements, and input/output interfaces.

- Performance Requirements: Evaluate your specific valve control requirements, such as the control range, precision, and response time. Make sure the module can meet these requirements to ensure efficient operation of your industrial process.

- Budget: Consider your budget constraints. While the IS200VSVOH1BED offers high – performance and reliability, compare its price with other available options to find the best value for your investment.

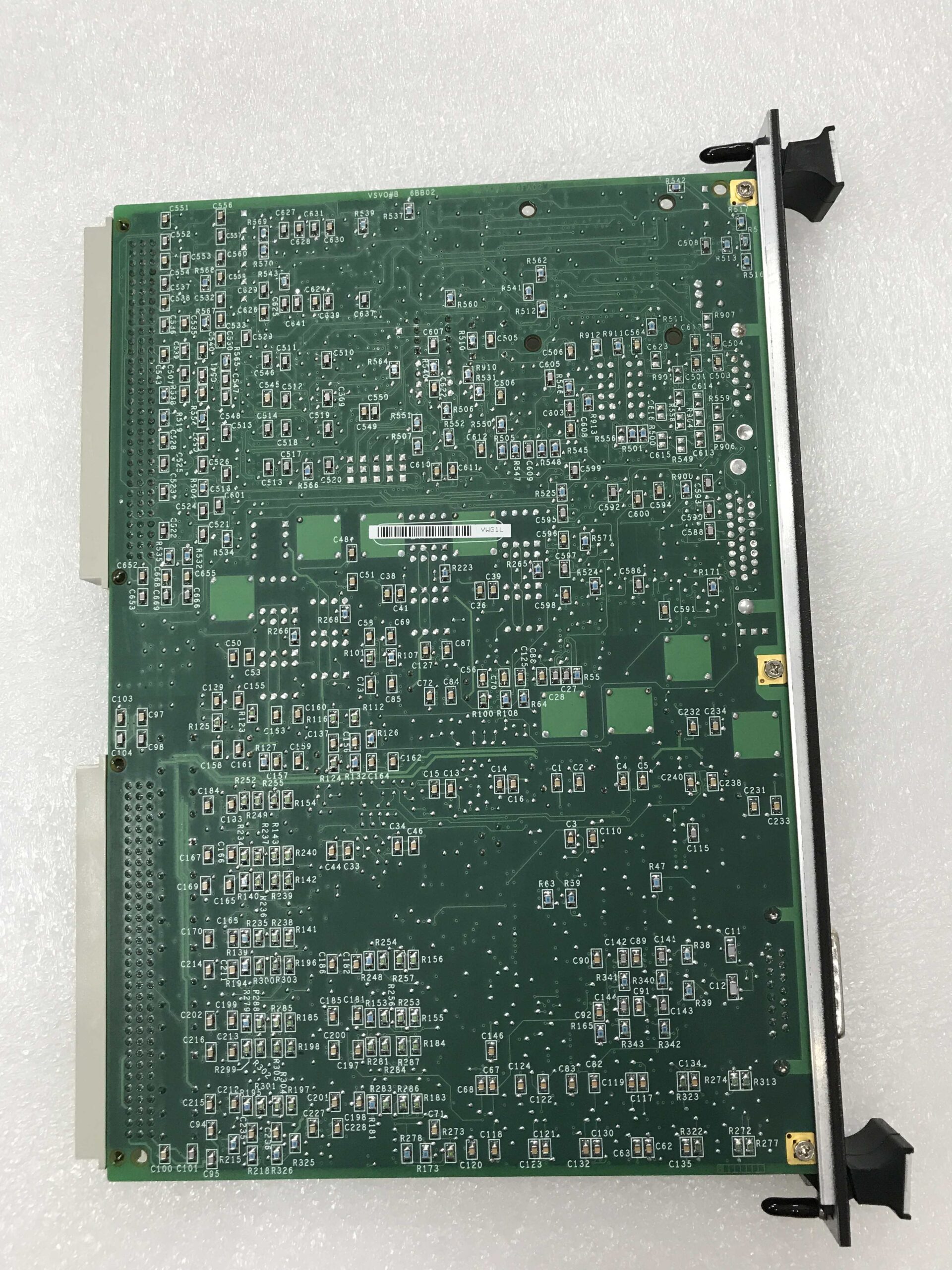

- Installation: Follow the installation instructions provided by the manufacturer carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module. Make sure all connections to the power supply, valves, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and valve control range. Regularly monitor the module’s performance and check for any error indicators or abnormal behavior.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris, and checking the integrity of the components. Replace any worn – out parts promptly to maintain the module’s reliability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide IS200VSVOH1BED and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide