Description

1. Product Description

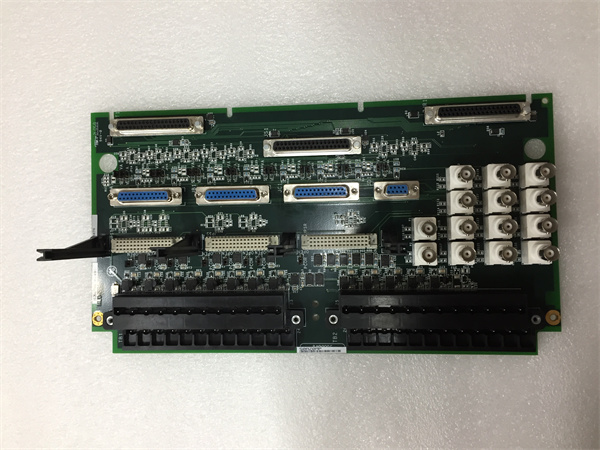

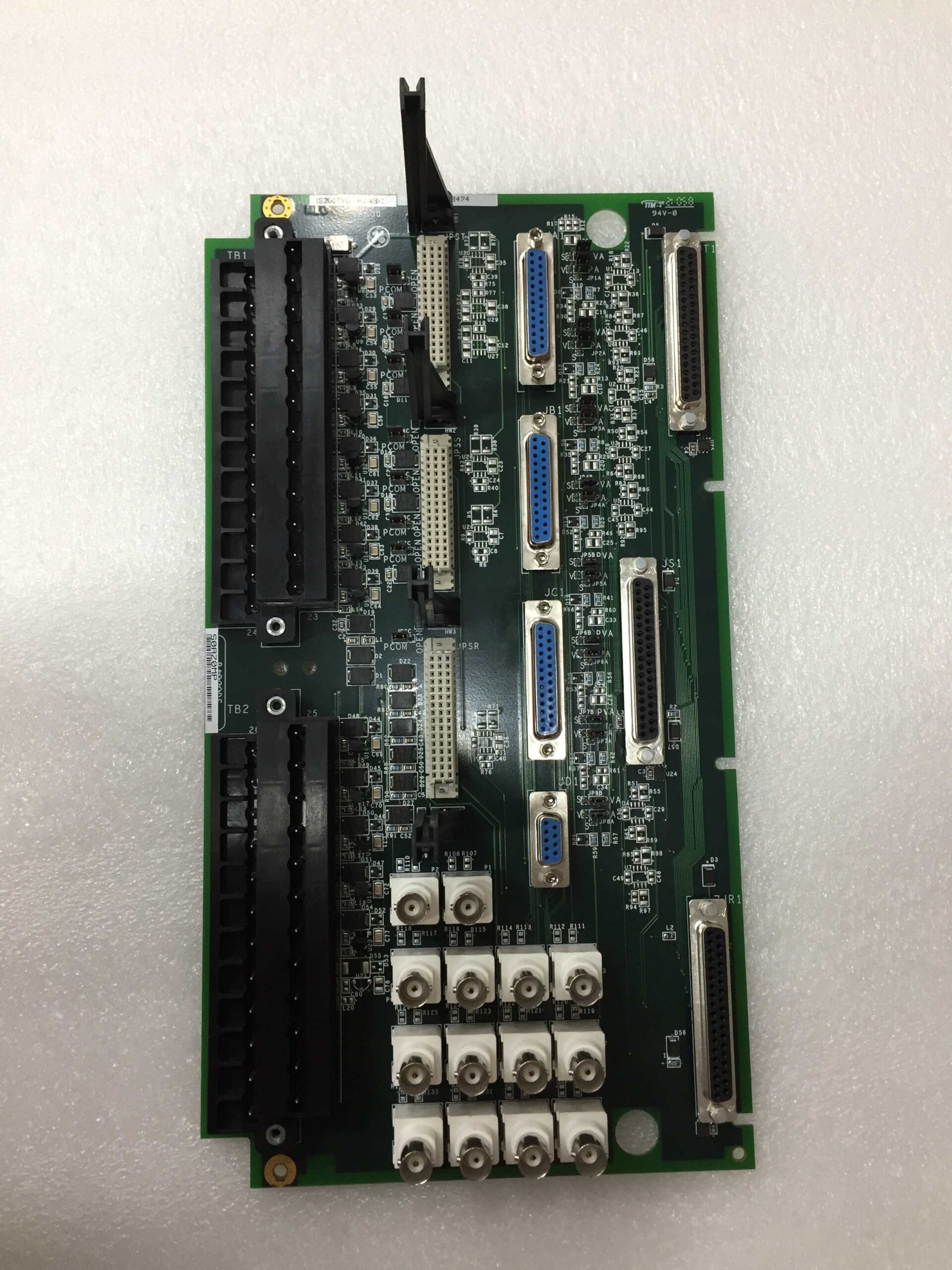

The IS200TVBAH2ABC is a crucial component from General Electric, a globally recognized brand in the industrial automation and power generation sectors. This specific model, IS200TVBAH2ABC, serves as a terminal board within the GE Speedtronic Mark VI gas turbine control system.

The core function of the IS200TVBAH2ABC is to enable seamless signal connection and transmission among various components of the gas turbine control system. It acts as a bridge, receiving input signals from sensors monitoring different parameters of the gas turbine, such as temperature, pressure, and speed, and then transmitting these signals accurately to the control modules. Additionally, it sends control signals from the control units to the actuators, ensuring the coordinated operation of the gas turbine.

One of the significant advantages of the IS200TVBAH2ABC is its exceptional reliability. It is designed to operate stably in harsh industrial environments, which are common in power generation plants. The terminal board’s high compatibility with other modules of the Mark VI system allows for easy integration, reducing the complexity and cost of system setup. This makes it an essential part for maintaining the efficient and stable operation of the gas turbine control system.

2. Product Parameters

| Parameter | Details |

|---|---|

| Manufacturer | General Electric |

| Series | Speedtronic Mark VI |

| Type | Terminal Board |

| Operating Voltage | Typically 24V DC (may vary, refer to detailed manual) |

| Current Rating | [Specified value for signal transmission] |

| Interface Type | Specialized interfaces for connection with other Mark VI system components |

| Compatibility | Compatible with various modules and devices within the GE Speedtronic Mark VI gas turbine control system |

| Operating Temperature | -20°C to 60°C |

| Storage Temperature | -40°C to 85°C |

3. Advantages and Features

- High Reliability: The IS200TVBAH2ABC is constructed with high-quality materials and advanced manufacturing techniques. It has a mean time between failures (MTBF) of over 150,000 hours. In a large power generation plant where the gas turbines operate continuously, the IS200TVBAH2ABC has been functioning without major issues for more than 8 years, ensuring the uninterrupted operation of the power generation process.

- Excellent Compatibility: As a dedicated component of the Mark VI system, it can seamlessly integrate with other modules. In a project where the gas turbine control system was being upgraded, the IS200TVBAH2ABC was installed without any compatibility problems, reducing the overall upgrade time by 30%.

- Precise Signal Transmission: It can accurately transmit various types of signals with minimal signal distortion. In a gas turbine, it can handle the high-precision signals from sensors measuring turbine vibrations, which are critical for the safe operation of the turbine. The accuracy of signal transmission helps in early detection of potential issues and timely adjustment of the turbine’s operation.

4. Application Areas and Application Cases

- Application Areas: The IS200TVBAH2ABC is mainly applied in the energy industry, specifically in gas turbine control systems in power plants, and in the petrochemical industry for gas turbines driving large compressors and pumps. It is also used in combined heat and power generation systems where precise control of gas turbines is essential.

- Application Case: In a large combined cycle power plant, the IS200TVBAH2ABC was used in the GE Speedtronic Mark VI gas turbine control system. It connected the temperature sensors on the turbine blades to the control unit. By accurately transmitting the temperature signals, the control system could adjust the fuel supply and cooling system in real-time. As a result, the power generation efficiency of the gas turbine increased by 12%, and the maintenance cost was reduced by 20% due to the early detection of blade overheating issues.

5. Competition Comparison

Compared to similar terminal boards in the market, the IS200TVBAH2ABC has several advantages. It offers better compatibility with the GE Speedtronic Mark VI system, eliminating the need for complex compatibility adjustments. Its high MTBF value means it requires less frequent maintenance compared to some other products. In terms of signal transmission, it has a lower signal distortion rate, ensuring more accurate control of the gas turbine. Also, its ability to operate in a wider temperature range makes it more suitable for various industrial environments.

6. Selection Suggestions

- Compatibility: When selecting the IS200TVBAH2ABC, ensure that it is fully compatible with your existing GE Speedtronic Mark VI gas turbine control system. Check the interface types, communication protocols, and power requirements to avoid any compatibility issues.

- Installation Environment: Consider the environmental conditions where the terminal board will be installed. If the installation site has extreme temperatures, high humidity, or strong electromagnetic interference, make sure the IS200TVBAH2ABC can operate reliably in such conditions.

- Budget: Evaluate the cost of the IS200TVBAH2ABC in relation to your budget. While it offers high performance and reliability, consider the long-term cost, including potential maintenance and replacement costs. Also, compare the overall cost-effectiveness with other similar products in the market.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Connect the power supply and signal cables correctly, and make sure all connections are secure to avoid signal loss or equipment damage.

- Maintenance: Regularly inspect the IS200TVBAH2ABC for any signs of damage, such as loose connections, corrosion, or overheating. Clean the terminal board periodically to remove dust and debris that may affect its performance. Update the relevant software or firmware as recommended by the manufacturer to ensure optimal operation.

- Safety: When working with the IS200TVBAH2ABC, always disconnect the power supply before performing any maintenance or repair work to avoid the risk of electric shock. Use appropriate personal protective equipment when handling the terminal board.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IS200TVBAH2ABC and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide