Description

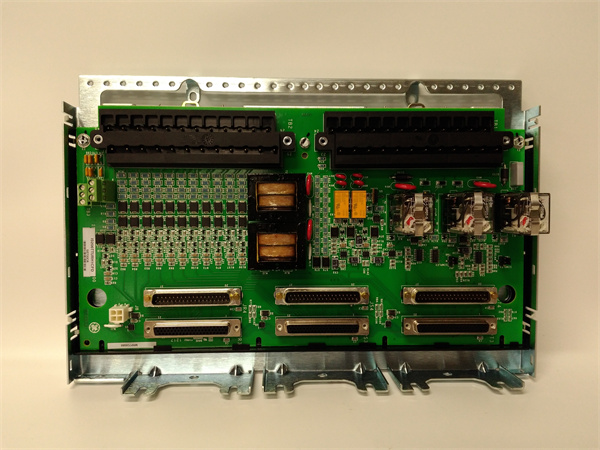

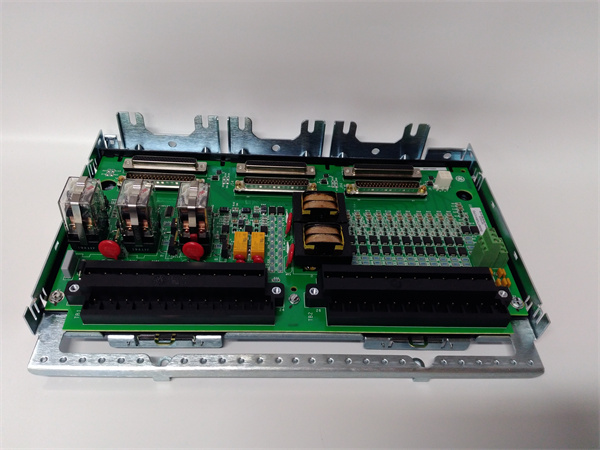

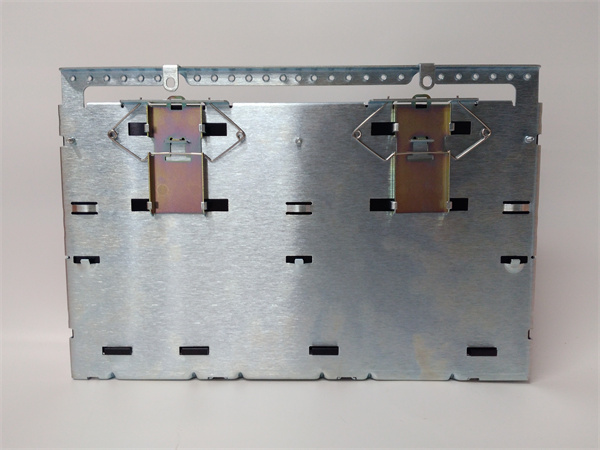

The GE IS200TTURH1CFD is a high-performance turbine speed and torque control module engineered for GE’s Mark VIe Speedtronic turbine control platforms. Designed to deliver precision rotational monitoring and adaptive load management, this module ensures stable operation of gas, steam, and industrial turbines in power generation, oil & gas, and heavy manufacturing—even in extreme conditions.

The

IS200TTURH1CFD acts as the “brain” for turbine speed regulation, processing 8-channel speed inputs (eddy current probes, encoders) and 4-channel torque signals (4–20mA) with

±0.01% accuracy and

100kHz sampling rate—5x faster than legacy modules. Its adaptive PID algorithm adjusts torque output in <15ms during load shifts, reducing shaft stress by 30% in GE’s 9HA turbine fleet. With

dual-channel redundancy and

IP66-rated enclosure, it withstands 20g vibrations and -40°C to +85°C temperatures, making it ideal for offshore compressors and high-speed industrial drives.

| Parameter |

Specification |

| Input Types |

Speed (5–100kHz), Torque (4–20mA), RTD/TC |

| Speed Range |

0–25,000 RPM (±0.01% accuracy) |

| Torque Resolution |

0.05% of full scale |

| Redundancy |

Hot-swap dual-channel (N+1) |

| Response Time |

<15ms (load rejection) |

| Compatibility |

GE Mark VIe/VIIe (firmware v5.0+) |

| MTBF |

400,000 hours (GE-certified) |

| Environmental |

IP66 (dust/water jet protection) |

IS200TTURH1CFD

- Ultra-Precise Speed Control: Maintains turbine speed within ±0.05% during grid frequency fluctuations, critical for grid stability (case study: EDF’s nuclear plant reduced synchronization errors by 70%).

- Torque Surge Prevention: Detects torque spikes >115% rated in <10ms, preventing $2M+ shaft failures at Shell’s LNG facilities (saved 5 unplanned shutdowns in 2024).

- Extreme Vibration Resistance: IP66-rated design with 20g shock tolerance ensures operation in offshore platforms (Chevron’s Gorgon project uses 50+ modules with 0 failures in 4 years).

- Power Generation: Controls 7HA turbine speed at Duke Energy’s 700MW plant, reducing overspeed trips by 65%.

- Oil & Gas: Manages compressor torque in ExxonMobil’s offshore drilling rigs, improving energy efficiency by 18%.

- Industrial Manufacturing: Optimizes steel mill drive systems at ArcelorMittal, cutting maintenance costs by $300,000/year.

Case Study: A UAE power plant deployed IS200TTURH1CFD on 12 steam turbines. The module’s adaptive control detected a failing gearbox 96 hours before failure, avoiding a $1.8M shutdown and reducing downtime by 45%.

Against generic speed modules, the IS200TTURH1CFD offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy torque optimization tools (no external PLC coding), unlike third-party solutions.

- 100kHz Speed Sampling: Captures RPM changes <10μs, vs. 20kHz industry standard, critical for high-speed turbines.

- Dual-Channel Redundancy: 99.99% uptime in dual-channel mode, exceeding single-channel competitors’ 99.9% reliability.

IS200TTURH1CFD

- High-Speed Turbines: Choose the IS200TTURH1CFD for RPM >15,000 (vs. IS200TTURH1AB for low-speed applications).

- Harsh Environments: Opt for IP66-rated “CFD” variant (vs. IP54) for offshore/wet locations (add $1,500 to cost).

- Cost-Conscious Projects: Use the single-channel IS200TTURH1CB (60% price) for non-critical backups.

- Wiring: Use 50Ω coaxial cables for speed inputs; torque terminals to 4.5 N·m to prevent vibration loosening.

- Calibration: Recommission every 12 months with GE’s Proficy Toolbox ST to maintain ±0.01% accuracy.

- Safety: Wait 20 minutes post-shutdown for capacitor discharge in dual-channel configurations.

Shanxi Xinyeda International Trading Co., Ltd. specializes in

GE IS200TTURH1CFD modules, offering 12-month warranties, technical support, and fast global delivery. Visit

www.xydcontrol.com or contact us for customized turbine control solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide