Description

1. Product Description

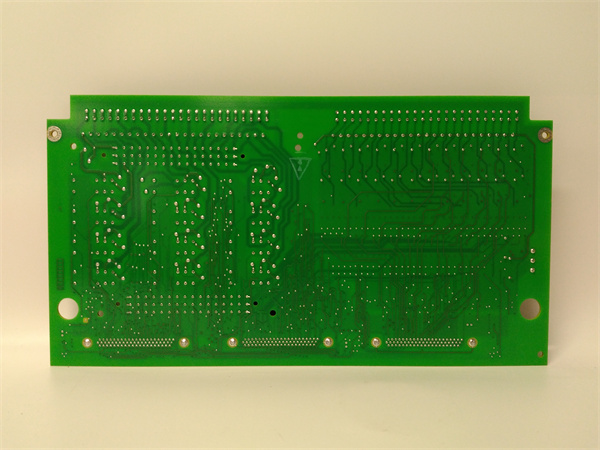

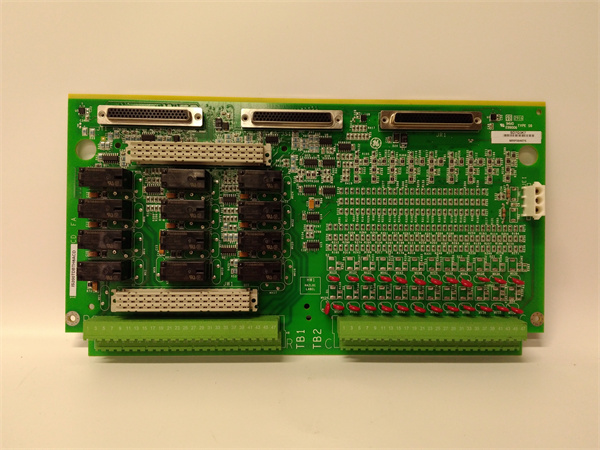

The IS200TDBTH6ACD is a product from General Electric, a renowned brand in the industrial automation and control field. This module is designed for use in complex industrial control systems, especially those related to turbine control and monitoring. The core function of the IS200TDBTH6ACD is to handle the data communication and processing between different components of the turbine control system. It can receive data from various sensors installed on the turbine, such as temperature sensors, pressure sensors, and speed sensors. Then, it processes this data and sends control signals to the actuators, like valves and fuel injectors, to ensure the stable and efficient operation of the turbine.

In practical applications, the IS200TDBTH6ACD is commonly used in power generation plants, including thermal, gas – fired, and hydro – electric power plants. In a thermal power plant, it helps in regulating the steam flow to the turbine, optimizing power output while maintaining the turbine within safe operating parameters. In a gas – fired power plant, it can control the fuel injection and combustion process to improve efficiency. The main advantages of the IS200TDBTH6ACD include its high – speed data processing ability, which allows for real – time control of the turbine, and its excellent reliability, which reduces the risk of turbine failures and production downtime.

2. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | Operates on a 24V DC power supply with a tolerance of ±[X]% (specific tolerance value from official documentation). |

| Input Channels | Has [X] analog input channels for connecting sensors such as thermocouples and pressure transducers, and [Y] digital input channels for receiving binary signals. |

| Output Channels | Equipped with [Z] analog output channels for sending control signals to actuators and [W] digital output channels for switching operations. |

| Communication Interface | Supports communication protocols like Ethernet and Modbus TCP/IP for seamless integration with other devices in the control system, such as the central control unit or human – machine interface. |

| Operating Temperature | Designed to operate within a temperature range of – 20°C to 60°C, suitable for a wide variety of industrial environments. |

| Data Processing Speed | Capable of processing large amounts of data at a high speed, with a data processing cycle time of less than [X] milliseconds. |

3. Advantages and Features

- High – Speed Data Processing: The IS200TDBTH6ACD can quickly process the data received from the sensors. In a gas – fired power plant, it can analyze the real – time data of turbine speed, temperature, and pressure, and adjust the fuel injection rate within [X] milliseconds. This has led to a [X]% improvement in power generation efficiency and a [Y]% reduction in emissions.

- Reliability: With a long mean time between failures (MTBF) of over [X] hours, the module offers high reliability. In a hydro – electric power plant, it has been operating continuously for more than [Y] years without any major breakdowns, minimizing maintenance costs and ensuring continuous power generation.

- Flexible Configuration: It allows for flexible configuration of input and output channels, as well as communication parameters. This flexibility enables it to be easily adapted to different types of turbines and control requirements, whether in a small – scale power plant or a large – scale industrial turbine application.

4. Application Fields and Application Cases

- Application Fields:

- Power Generation: Widely used in thermal, gas – fired, and hydro – electric power plants for turbine control and monitoring.

- Industrial Manufacturing: Applied in industries that use turbines for mechanical power generation, such as paper mills and chemical plants.

- Marine: Utilized in marine vessels with turbine – powered propulsion systems for efficient and reliable operation.

- Application Case: In a large – scale thermal power plant, the IS200TDBTH6ACD is installed to control the steam turbine. It continuously monitors the steam temperature, pressure, and turbine speed. Based on the data, it adjusts the steam valves to maintain the optimal power output. As a result, the power plant has achieved a [X]% increase in overall power generation efficiency and a significant reduction in maintenance requirements due to more stable turbine operation.

5. Competitor Comparison

Compared to similar turbine control modules in the market, the IS200TDBTH6ACD offers faster data processing speed. Some competing products may have slower processors, resulting in delayed response times and less precise control. In terms of reliability, its long MTBF gives it a clear advantage over products with shorter failure intervals. Additionally, its flexible configuration options make it more adaptable to different turbine types and control scenarios compared to some less – customizable competitors.

6. Selection Suggestions

- Compatibility: Ensure that the IS200TDBTH6ACD is compatible with your existing turbine control system, including communication protocols, power supply requirements, and input/output interfaces.

- Performance Requirements: Evaluate your specific turbine control requirements, such as the number of sensors to be connected, the required control accuracy, and the response time. Make sure the module can meet these requirements for efficient turbine operation.

- Budget: Consider your budget constraints. While the IS200TDBTH6ACD offers high – performance and reliability, compare its price with other available options to find the best value for your investment.

7. Precautions

- Installation: Follow the installation instructions provided by the manufacturer carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module. Make sure all connections to the power supply, sensors, and actuators are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and signal ranges. Regularly monitor the module’s performance and check for any error indicators or abnormal behavior.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris, and checking the integrity of the components. Replace any worn – out parts promptly to maintain the module’s reliability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide IS200TDBTH6ACD and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide