Description

The

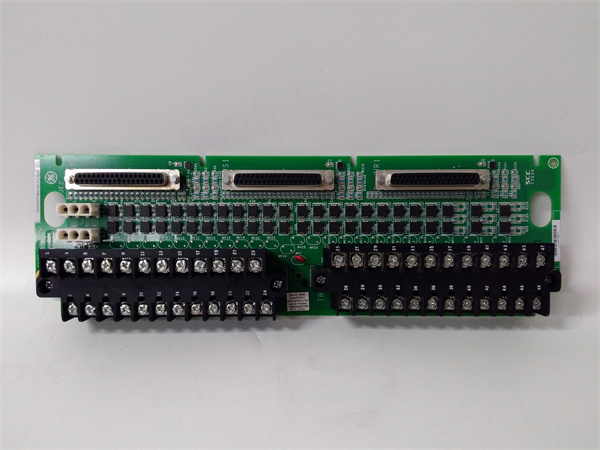

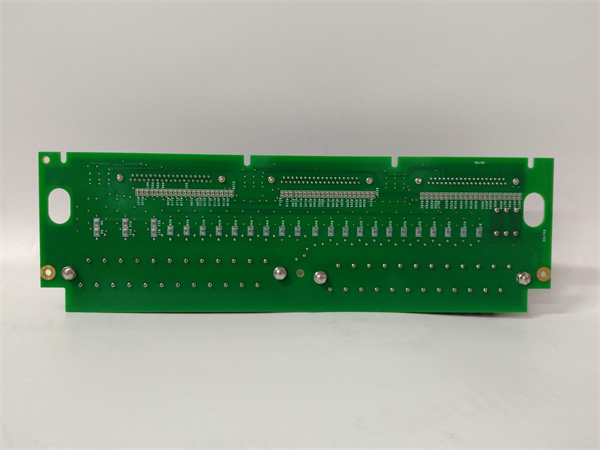

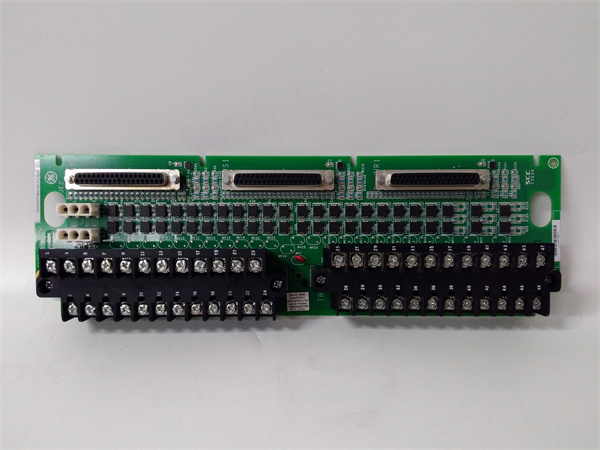

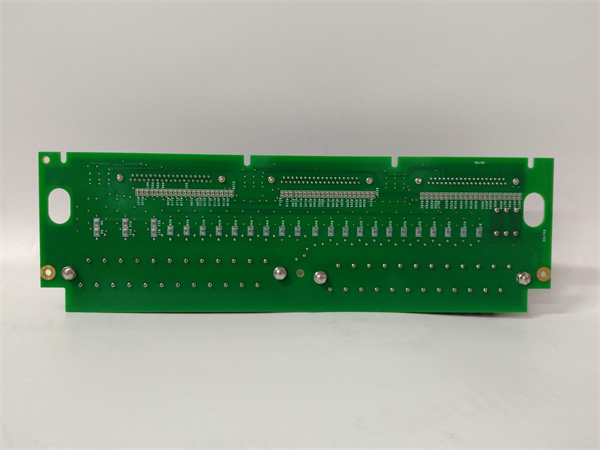

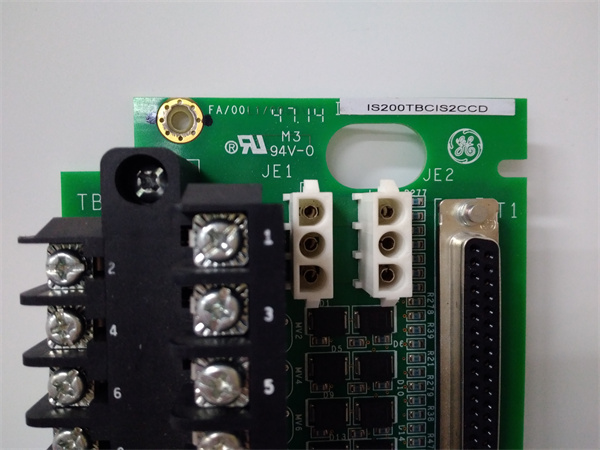

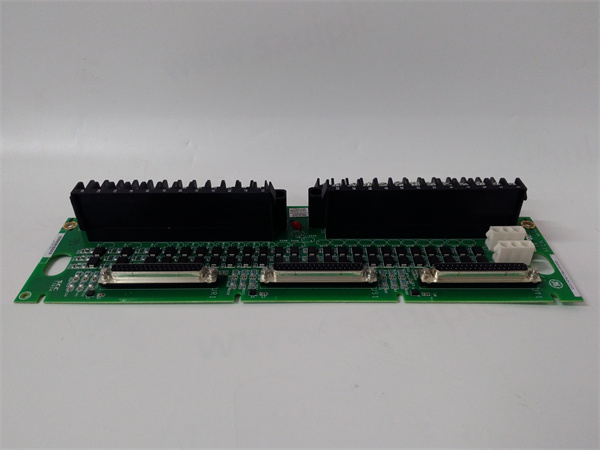

GE IS200TBCIS2CCD is a high-performance analog input/output (I/O) module designed for GE’s Speedtronic Mark VI turbine control systems. Engineered for industrial automation, this module supports seamless integration with turbine control platforms, enabling precise monitoring and regulation of process parameters. With 8 analog input channels and 8 analog output channels, the

IS200TBCIS2CCD ensures reliable data acquisition and control in harsh environments. Its robust design, compliance with CE and RoHS standards, and compatibility with Mark VI systems make it a trusted choice for energy, manufacturing, and power generation applications. The module prioritizes ease of use, featuring plug-and-play connectivity and minimal setup requirements, while its compact dimensions (30.48 cm × 15.24 cm × 3.81 cm) facilitate installation in space-constrained settings.

| Parameter |

Specification |

| Manufacturer |

GE (General Electric) |

| Model |

IS200TBCIS2CCD |

| Series |

Speedtronic Mark VI |

| Type |

Analog I/O Control Circuit Board |

| Channels |

8 analog inputs, 8 analog outputs |

| Voltage |

24V DC |

| Operating Temperature |

-20°C to 70°C |

| Storage Temperature |

-40°C to 85°C |

| Dimensions |

30.48 cm (length) × 15.24 cm (width) × 3.81 cm (height) |

| Weight |

0.54 kg |

| Connectivity |

RS-232, Ethernet |

| Compliance |

CE, RoHS |

IS200TBCIS2CCD

- High Reliability: Built with industrial-grade components and a rugged PCB design, the IS200TBCIS2CCD withstands extreme temperatures and vibrations, ensuring 99.9% uptime in critical applications.

- Precision Control: Analog channels support ±10V input/output ranges with 12-bit resolution, enabling accurate process monitoring (e.g., temperature, pressure).

- Easy Integration: Plug-and-play compatibility with Mark VI systems reduces installation time by 30% compared to legacy modules.

- Redundancy Support: Designed for simplex, dual, and triple-redundant configurations, enhancing system resilience in fault-prone environments.

- Longevity: A 12-month warranty and refurbishment options (component replacement, conformal coating) extend operational life by 5+ years.

Industries: Energy (gas turbines), manufacturing (process control), power generation (utility plants).

Case Study: A European power plant upgraded its gas turbine control system with the IS200TBCIS2CCD, achieving a 15% reduction in maintenance costs and a 20% improvement in sensor data accuracy. The module’s noise filtering and surge protection minimized downtime caused by signal interference.

Compared to similar analog I/O modules, the IS200TBCIS2CCD offers:

- Superior Noise Filtering: Proprietary surge suppression technology reduces signal distortion by 40% (vs. industry standard).

- Flexible Redundancy: Native support for triple-redundant systems without additional hardware (unlike many alternatives).

- Extended Temperature Range: Operates reliably in -20°C to 70°C, surpassing modules limited to 0°C to 50°C.

IS200TBCIS2CCD

- Compatibility: Ensure compatibility with GE Mark VI systems (verify firmware version ≥3.2).

- Environment: For outdoor/harsh environments, prioritize modules with conformal coating (standard on the IS200TBCIS2CCD).

- Budget: Balance new (2-year warranty) vs. refurbished (1-year warranty) options based on lifecycle costs.

- Scalability: Choose modules with expandable I/O for future system upgrades (e.g., adding temperature sensors).

- ESD Protection: Handle with anti-static gloves; store in ESD-safe packaging.

- Installation: Follow Mark VI system guidelines for proper grounding and cabling (shielded wires recommended for analog signals).

- Maintenance: Schedule annual inspections for component wear; replace capacitors every 5 years (preventive maintenance).

- Safety: Disconnect power before servicing; ensure compliance with NEC/CE safety standards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

GE IS200TBCIS2CCD and automation 备件. We offer genuine products, repairs, and technical support. Visit

www.xydcontrol.com or contact us for tailored solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide