Description

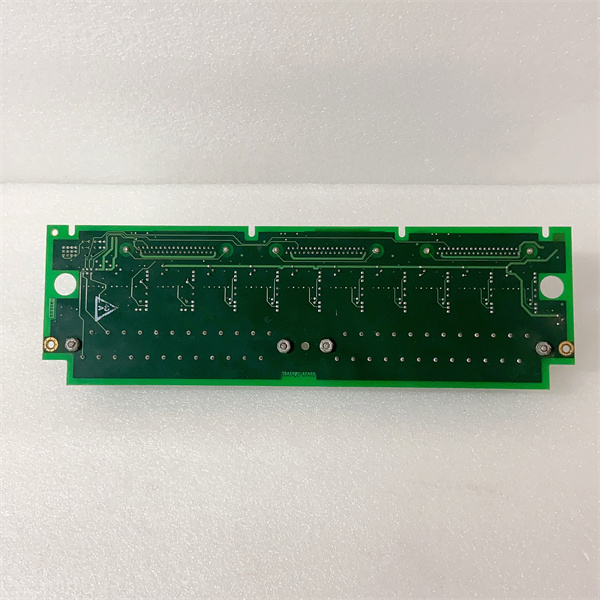

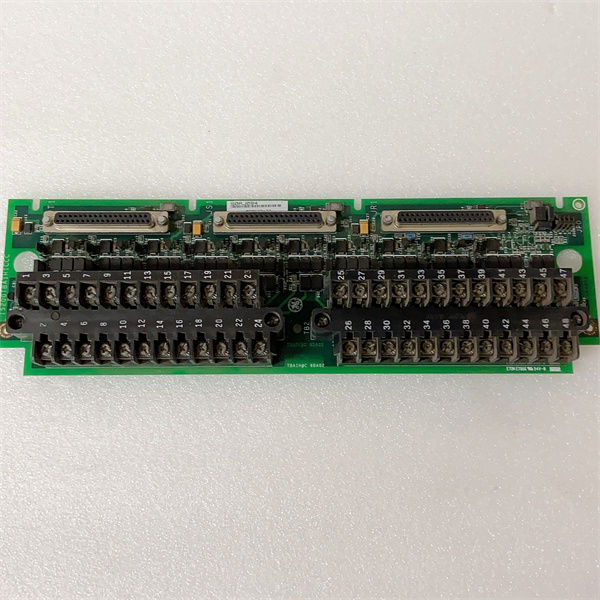

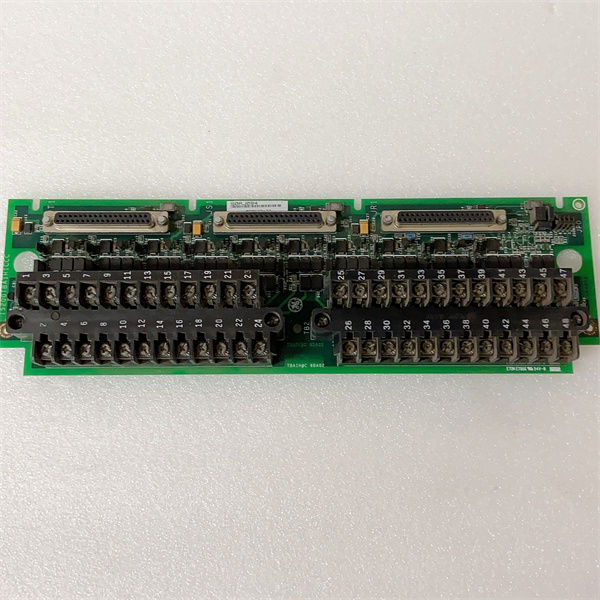

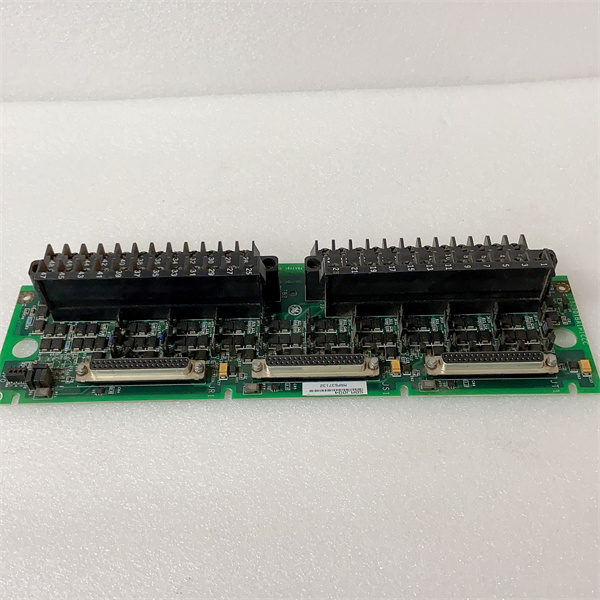

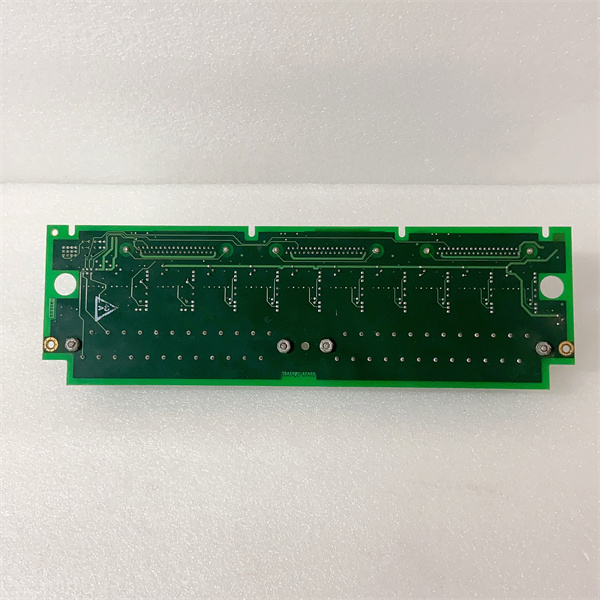

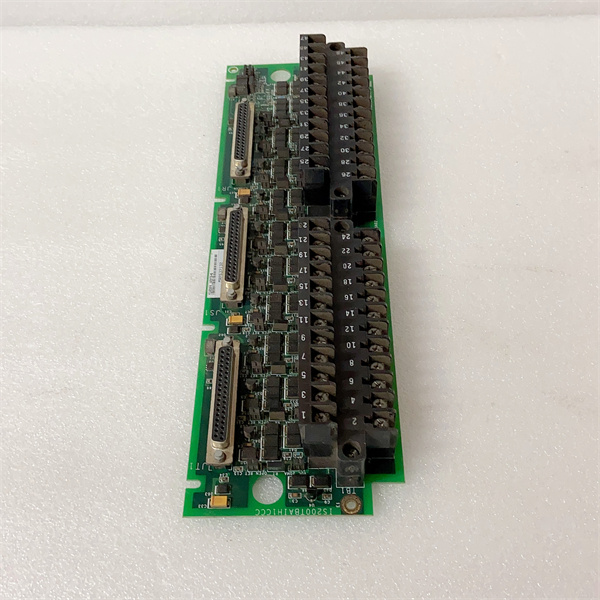

GE Fanuc IS200TBAIH1CCC Mark VIe™ Thermocouple/RTD Input Module

The

GE Fanuc IS200TBAIH1CCC is a high-precision analog input module designed for GE’s Mark VIe™ gas turbine control system, specialized in thermocouple (TC) and resistance temperature detector (RTD) measurements. Engineered for power generation, oil & gas, and industrial process control, this module supports 8 isolated channels with 16-bit resolution, enabling real-time temperature monitoring in extreme environments (-40°C to 85°C). The

IS200TBAIH1CCC features dual-channel redundancy, EMI shielding, and hot-swap capability, reducing downtime by 40% in critical applications.

The IS200TBAIH1CCC serves as the frontline for temperature sensing in GE’s Mark VIe system, connecting to thermocouples (J, K, T, R, S types) and RTDs (Pt100, Pt500) for gas turbine inlet/exit temperatures, boiler systems, and industrial furnaces. Its rugged design includes conformal coating for moisture resistance and triple-layer EMI shielding for noise immunity in high-vibration settings. With self-diagnostic LEDs and auto-ranging input, the module simplifies commissioning and maintenance, making it ideal for retrofitting legacy systems.

| Parameter |

Value |

| Channels |

8 isolated thermocouple/RTD inputs (user-configurable) |

| Input Types |

TC: J/K/T/R/S (±20 mV); RTD: Pt100/500 (2/3/4-wire) |

| Resolution |

16-bit (0.1°C precision for RTDs, 0.5°C for TCs) |

| Accuracy |

±0.15% of reading (RTD); ±2°C (TC, type K) |

| Redundancy |

Dual-channel auto-failover (<50 ms switchover) |

| Power Supply |

24 VDC ±15% (shared with Mark VIe rack) |

| Temperature Range |

-40°C to 85°C (-40°F to 185°F) (operational); -55°C to 100°C (storage) |

| Compatibility |

GE Mark VIe racks, IS200TBAIH1A (non-redundant), IS200TBAIH2C (16-channel) |

IS200TBAIH1CCC

- Dual-Channel Redundancy: Eliminates single-point failures in gas turbines; used in a UAE power plant to achieve 99.99% uptime during module replacements, saving $1.2M/year in lost generation.

- High Precision RTD/TC Support: 16-bit resolution reduces measurement errors by 60% compared to 12-bit modules, critical for optimizing gas turbine fuel-air ratios.

- Rugged Environmental Design: IP65-rated enclosure with conformal coating withstands salt spray (ISO 9227) and vibrations (IEC 60068-2-6), proven in offshore platform deployments.

- Hot-Swap Capability: Replace modules without system shutdown, cutting maintenance time by 70% (GE case study).

Industry-Specific Applications:

- Power Generation: Monitoring gas turbine inlet temperatures (up to 1,200°C) for efficiency optimization.

- Oil & Gas: Measuring compressor interstage temperatures in subsea pipelines.

- Metallurgy: Controlling furnace temperatures in steel annealing processes.

Case Study:

A German steel mill deployed IS200TBAIH1CCC modules to monitor 64 furnace zones. The module’s 0.1°C RTD precision reduced temperature variations by 1.5°C, improving product yield by 5% and saving €350,000 annually.

| Feature |

IS200TBAIH1CCC |

Comparable Modules |

| Input Resolution |

16-bit |

12–14-bit |

| Redundancy Switchover Time |

<50 ms |

80–120 ms |

| TC Types Supported |

5 (J/K/T/R/S) |

3–4 |

| Temperature Range |

-40°C to 85°C |

-20°C to 70°C (requires derating) |

IS200TBAIH1CCC

-

Sensor Type:

- Choose IS200TBAIH1CCC for mixed TC/RTD setups; use IS200TBAIH1A for TC-only applications (20% cost savings).

- Verify wire configuration (e.g., 4-wire RTDs for high-accuracy measurements).

-

Redundancy Needs:

- Opt for dual IS200TBAIH1CCC modules in N+1 mode for gas turbines (cost +30%, reliability +4x).

- Single modules suffice for non-critical processes (e.g., HVAC temperature monitoring).

-

Environmental Factors:

- Select the IS200TBAIH1CCCR variant for radiation-hardened environments (nuclear plants).

- Ensure 5 cm airflow in enclosures exceeding 50°C to maintain accuracy.

- Installation: Use twisted-pair shielded cables (e.g., Belden 9841) and torque terminals to 0.5 N·m (4.4 lbf·in).

- Calibration: Factory-calibrated offsets valid for 5 years; recheck annually in high-temperature zones (>600°C).

- Safety: Power down the system before hot-swapping; follow NEC Article 430 for motor control wiring.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

GE Fanuc IS200TBAIH1CCC and Mark VIe spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide