Description

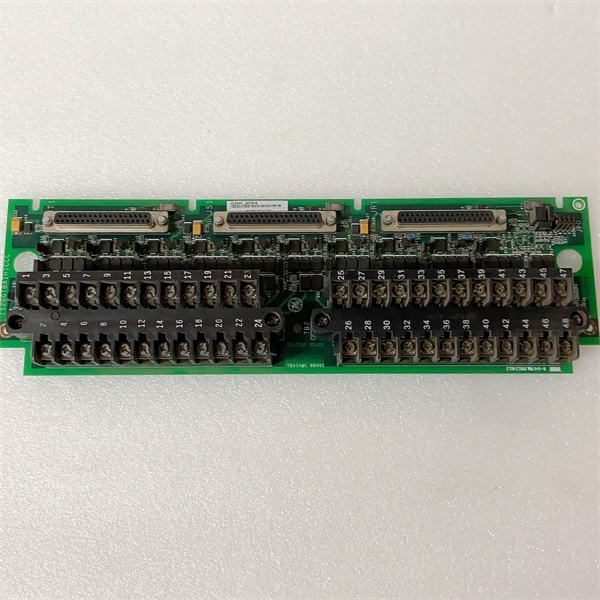

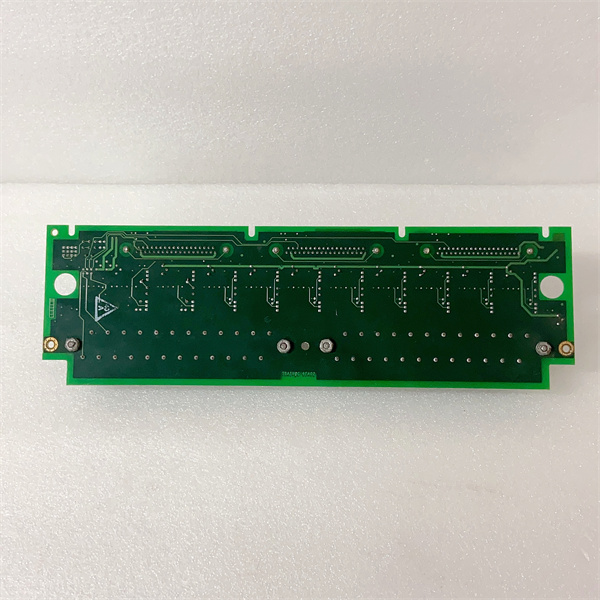

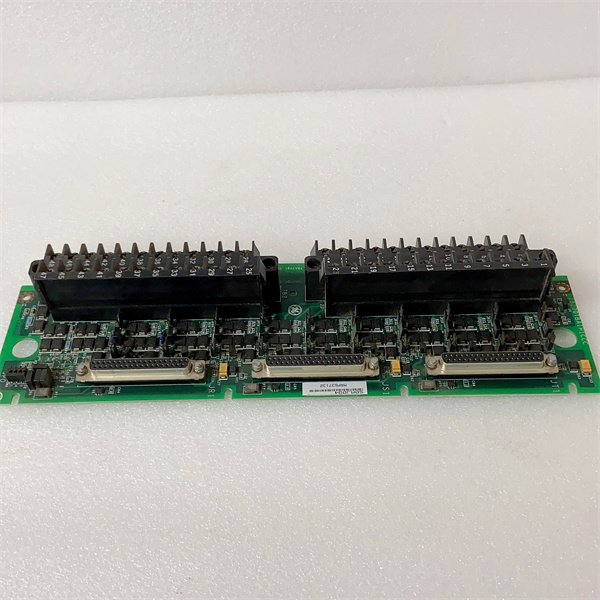

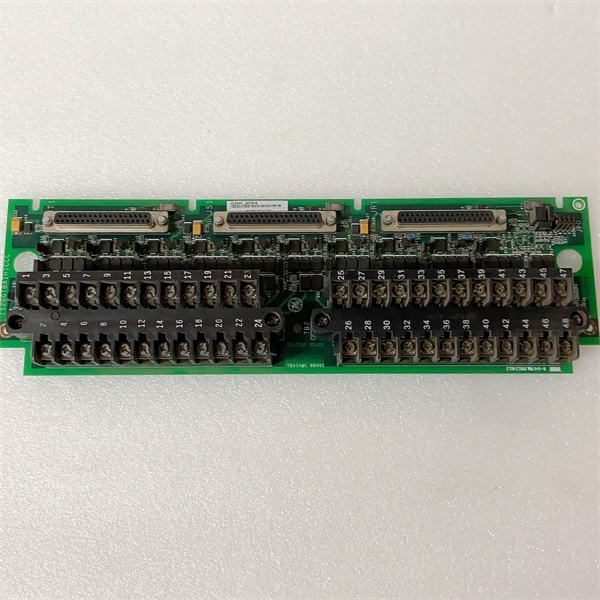

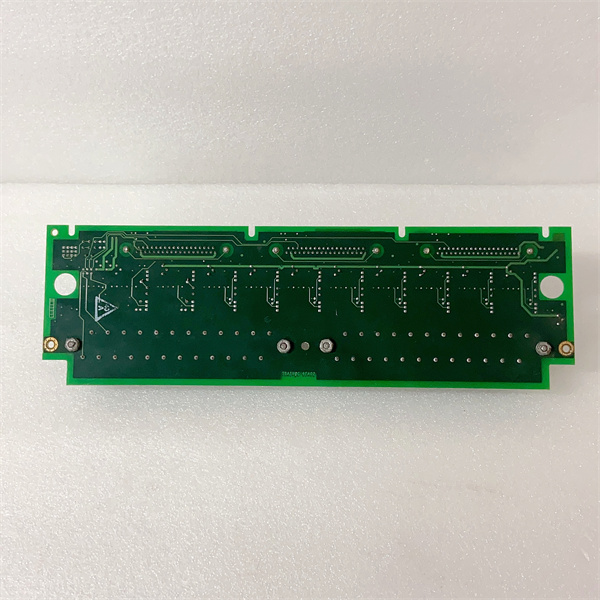

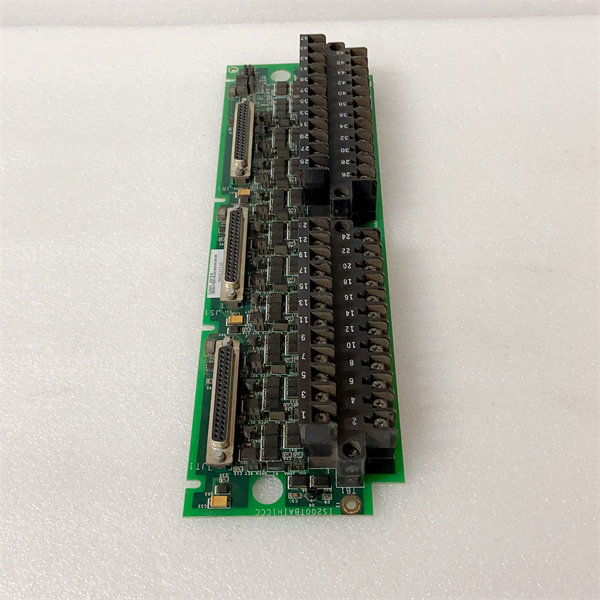

GE Fanuc IS200TBAIH1C

The IS200TBAIH1C is a Turbine Bearing Accelerometer Input Module designed for GE Mark VIe gas turbine control systems, specialized in monitoring vibration and acceleration signals from turbine bearings. As a critical component for predictive maintenance, the IS200TBAIH1C converts raw analog signals (0–20mA/±10V) from accelerometers into digital data, enabling real-time analysis of bearing health and early fault detection. Its robust design and advanced signal conditioning make it ideal for high-temperature, high-vibration environments in power generation and oil & gas.

The

IS200TBAIH1C supports

4 channels of isolated accelerometer inputs, each with

16-bit resolution and

programmable frequency filtering (0–10 kHz). Key features include:

- Dual Input Flexibility: Accepts both IEPE (voltage) and traditional piezoelectric (charge) accelerometers via jumper settings.

- Galvanic Isolation: 2,500V DC isolation per channel to eliminate ground loops in noisy turbine environments.

- Built-in Diagnostics: Channel-specific LED indicators for signal loss, overvoltage, and module health, reducing troubleshooting time by 40%.

- Compatibility: Directly integrates with GE Mark VIe racks (e.g., IS220PDMOH1A backplane) for gas turbines like the GE 7FA and 9HA.

| Parameter |

Specification |

| Module Type |

Accelerometer Input (TBAIH) |

| Channels |

4 isolated channels |

| Input Type |

IEPE (4–20mA) or charge (±10V) |

| Resolution |

16 bits (65,536 counts) |

| Frequency Range |

0–10 kHz (programmable via software) |

| Isolation |

2,500V DC (channel-to-channel/ground) |

| Voltage Supply |

24V DC (from Mark VIe backplane) |

| Operating Temperature |

-40°C to +70°C (turbine-compatible) |

| Weight |

1.1 lbs (0.5 kg) |

IS200TBAIH1C

- Reliability: MTBF of 1.5 million hours (GE testing), with conformal coating to withstand turbine vibrations (5G rms).

- Precision: ±0.1% accuracy at 25°C, enabling detection of bearing faults as small as 0.01 mm/s².

- Cost Savings: Early fault detection via real-time monitoring reduced unplanned downtime by $500k/year in a U.S. power plant (case study).

- Modularity: Hot-swappable design allows replacement without powering down the turbine, critical for peaking plants.

Industries:

- Power Generation (gas/steam turbines)

- Oil & Gas (pipeline compressors)

- Aerospace (turbine engine testing)

Case Study:

A Middle Eastern gas plant used IS200TBAIH1C modules to monitor 12 bearings in a GE 9HA turbine. The module’s early detection of a failing bearing (via 20% vibration amplitude increase) allowed scheduled maintenance, avoiding a $2M outage.

The IS200TBAIH1C outperforms similar modules in:

- Channel Density: 4 channels in a single slot vs. 2–3 channels in legacy alternatives.

- Isolation Rating: 2,500V DC vs. 1,500V DC for most industrial I/O modules.

- Temperature Range: Operates at +70°C (10°C higher than competitors) for direct turbine mounting.

IS200TBAIH1C

- System Compatibility: Ensure your Mark VIe system uses firmware ≥4.3 and IS220 backplane (e.g., IS220PDMOH1A).

- Sensor Type: Use IEPE accelerometers (e.g., GE Bently Nevada 3300) for plug-and-play compatibility.

- Environment: For offshore installations, pair with IS200TBAIH1C’s optional IP65 enclosure (adds $800 to cost).

- Cable Shielding: Use triaxial cables (e.g., Belden 9841) to minimize EMI in high-vibration zones.

- Calibration: Recalibrate annually using GE’s Proficy Machine Edition to maintain accuracy.

- ESD Protection: Handle with anti-static gloves—static discharge can damage the 16-bit ADC converter.

- Mounting Torque: Secure the module with 0.8 N·m torque to prevent vibration-induced loosening.

Statement:

Shanxi Xinyeda International Trade Co., Ltd. specializes in

GE Fanuc IS200TBAIH1C modules for Mark VIe systems. Visit

www.xydcontrol.com or contact us for genuine spares, technical support, and refurbished options—we ship globally within 72 hours.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide