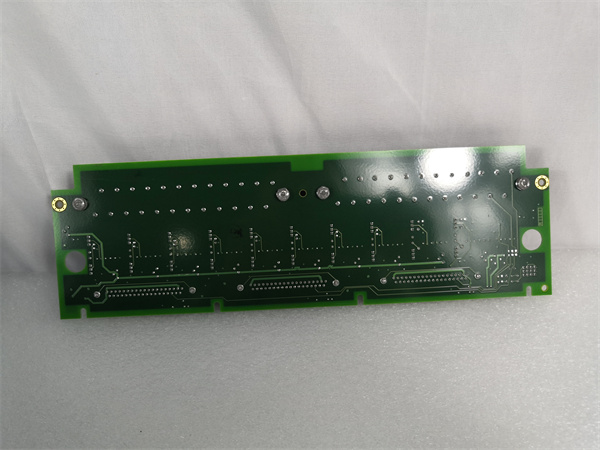

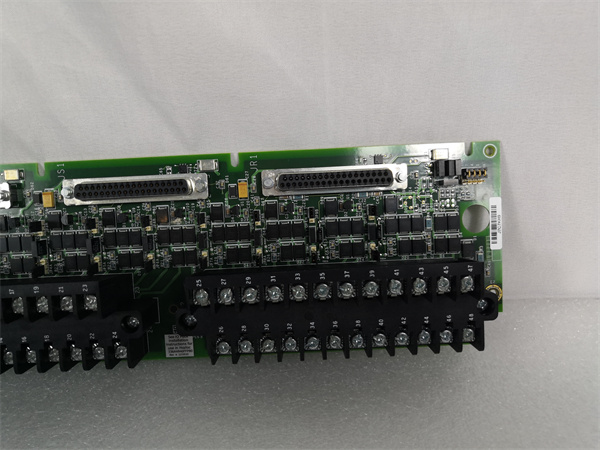

Description

1. Product Description

The IS200TBACIH1B is designed with advanced technology and a focus on providing precise control and monitoring capabilities for gas turbines in industrial automation systems. Its core function is to accurately process signals related to the operation of gas turbines, such as parameters like temperature, pressure, and speed. This card enables the monitoring and adjustment of these parameters to ensure the stable and efficient operation of the gas turbine.

In industrial applications, the IS200TBACIH1B is used to manage the control systems of gas turbines. It interfaces with various sensors and actuators to collect real-time data and send control signals, allowing for the optimization of the gas turbine’s performance. One of the main advantages of the IS200TBACIH1B is its high reliability. Built with high-quality electronic components and advanced manufacturing processes, it can withstand harsh industrial environments and operate continuously for extended periods without significant failures. Additionally, its good compatibility with other industrial automation equipment and systems makes it a flexible choice for system integration, enabling seamless connection and cooperation with different components.

2. Product Parameters

| Parameter | Details |

|---|---|

| Operating Voltage | Typically around 24V DC |

| Interface Types | Digital input/output interfaces, communication interfaces (such as Ethernet, RS485) |

| Dimensions | Conforms to standard industrial card dimensions for easy installation in control cabinets |

| Compatibility | Compatible with various GE gas turbine control systems and related industrial automation systems |

| Operating Temperature Range | 0°C – 55°C |

| Storage Temperature Range | -40°C – 85°C |

| Humidity | 5% – 95% non-condensing |

3. Advantages and Features

- High Reliability: The IS200TBACIH1B uses top-notch components and undergoes strict quality control. It has an average mean time between failures (MTBF) of over 80,000 hours. In a steel factory with high temperatures and strong electromagnetic interference, the IS200TBACIH1B has been operating steadily for more than 6 years, ensuring the normal operation of the gas turbine control system in this harsh environment.

- Precise Control: It can accurately monitor and control various parameters of the gas turbine. For example, in a power generation plant, the IS200TBACIH1B can control the gas turbine’s combustion efficiency with an accuracy of up to 98%, optimizing the power generation process and reducing energy consumption.

- Easy Integration: With standardized interfaces and communication protocols, integrating the IS200TBACIH1B into existing industrial automation systems is straightforward. In a factory’s automation upgrade project, it only took 2 days to integrate the IS200TBACIH1B with other equipment, significantly reducing the project implementation time compared to some less compatible components.

4. Application Areas and Application Cases

- Application Areas:

- Energy Industry: Widely used in power plants, including thermal power plants and gas-fired power plants, for the control and monitoring of gas turbines.

- Petrochemical Industry: Applied to control the gas turbine equipment in the production process to ensure stable operation and efficient energy utilization.

- Industrial Manufacturing: Used in large industrial manufacturing enterprises to control the gas turbines that drive large equipment.

- Application Case: In a large gas-fired power plant, the IS200TBACIH1B was installed in the gas turbine control system. By precisely controlling the gas turbine’s operation parameters, it increased the power generation efficiency by 10%. The card continuously monitored the turbine’s performance and made real-time adjustments, reducing the frequency of equipment failures and maintenance costs. As a result, the power plant was able to generate more electricity with less fuel consumption, improving its overall economic benefits.

5. Competitor Comparison

Compared with similar products in the market, the IS200TBACIH1B has several distinct advantages. In terms of reliability, its long MTBF and ability to operate in harsh environments outperform many other products. Regarding control accuracy, it can achieve a higher level of precision in parameter control, which is crucial for optimizing the performance of gas turbines. Moreover, its wide compatibility allows for easier integration with a broader range of industrial automation equipment, while some competing products may face compatibility issues and require additional adaptation efforts.

6. Selection Suggestions

- Compatibility: When selecting the IS200TBACIH1B, make sure it is fully compatible with your existing industrial automation system, including communication protocols and interface types. Check the technical specifications of your system to ensure seamless integration.

- Installation Environment: Consider the environmental conditions where the IS200TBACIH1B will be installed. Although it can operate within a certain temperature and humidity range, extreme conditions may require additional protective measures. Ensure that the installation location has proper ventilation and protection against dust and moisture.

- Budget: While the IS200TBACIH1B offers high performance and reliability, compare its price with your budget. Also, consider the long-term cost savings due to its stable operation and low maintenance requirements. Evaluate whether the features and performance it provides justify the investment for your specific application.

7. Precautions

- Installation: When installing the IS200TBACIH1B, follow the manufacturer’s installation instructions carefully. Ensure that the power supply voltage is within the specified range and that all connections are secure. Use appropriate cables and connectors to prevent electrical interference.

- Maintenance: Regularly check the operation status of the IS200TBACIH1B. Clean the card to remove dust and debris that may affect its performance. Monitor the temperature and humidity around the card to ensure they are within the normal range. Periodically check the connections and replace any damaged components in a timely manner.

- Safety: Before performing any maintenance or repair work on the IS200TBACIH1B, disconnect the power supply to avoid the risk of electric shock. Wear appropriate personal protective equipment when handling the card to prevent damage to the device and ensure your safety.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide [IS200TBACIH1B] and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide