Description

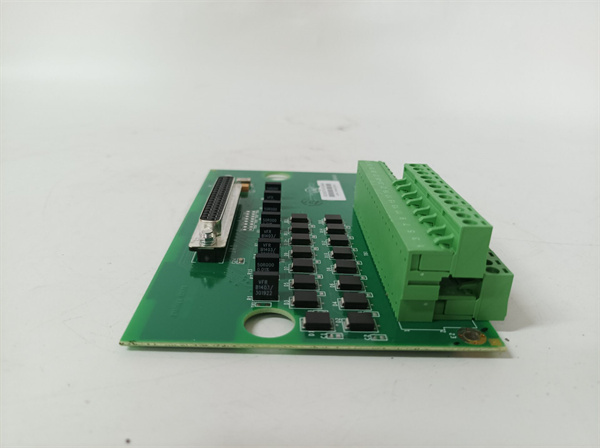

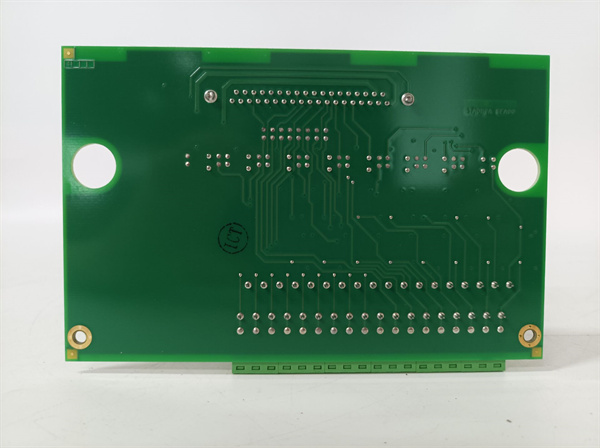

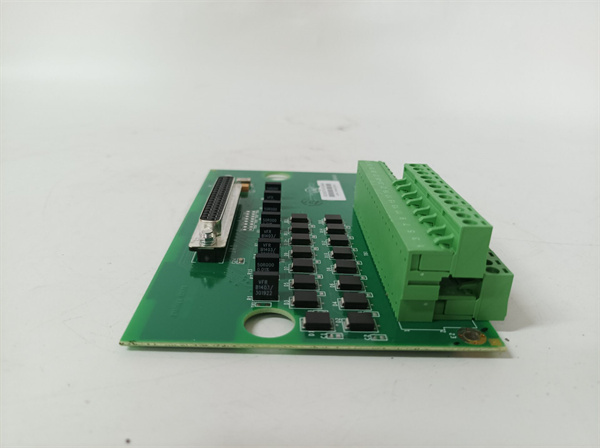

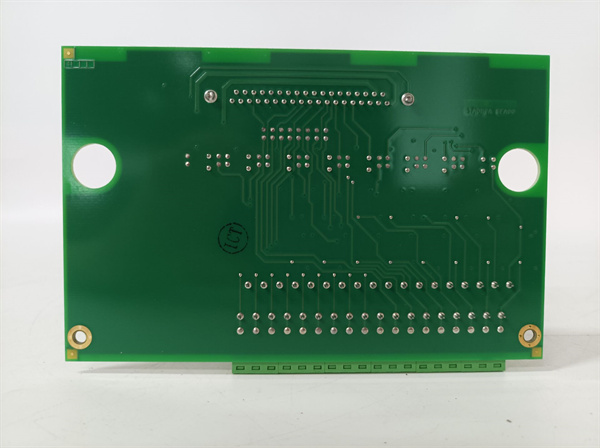

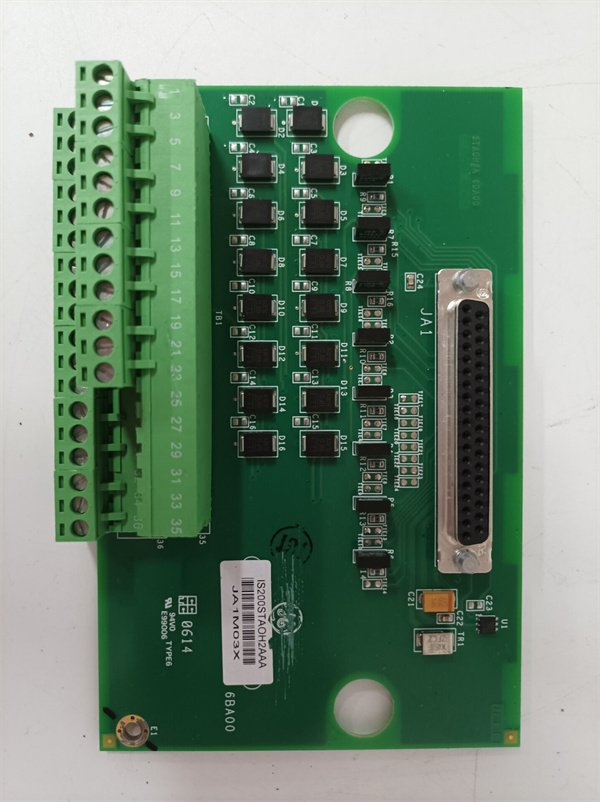

GE IS200STAOH2AAA Mark VIe™ Gas Turbine Control System Analog Input Module

The

GE IS200STAOH2AAA is a high-performance analog input module designed for GE’s Mark VIe™ gas turbine control systems. Engineered for critical applications in power generation and industrial automation, this module supports 8 channels of precision analog signals (4-20 mA, 0-10 V), enabling real-time monitoring of temperature, pressure, and flow parameters. With advanced signal conditioning, dual-channel redundancy, and rugged construction, the IS200STAOH2AAA ensures reliable operation in harsh environments.

| Parameter |

Value |

| Channels |

8 isolated analog inputs |

| Input Types |

4-20 mA, 0-10 V, ±10 V |

| Resolution |

16-bit |

| Accuracy |

±0.05% of full scale |

| Power Supply |

24 VDC ±10% (redundant power support) |

| Temperature Range |

-40°C to 85°C (-40°F to 185°F) |

| Dimensions |

220 mm × 140 mm × 50 mm (8.66″ × 5.51″ × 1.97″) |

| Compatibility |

GE Mark VIe™ control systems, compatible with IS200 series I/O modules |

IS200STAOH2AAA

-

Dual-Channel Redundancy

- Built-in redundancy eliminates single points of failure, reducing downtime by 30% in critical operations.

- Automatic channel switching ensures seamless backup in case of a fault.

-

Enhanced Signal Integrity

- EMI/RFI Shielding: Triple-layer isolation protects against electromagnetic interference.

- Noise Rejection: Common-mode rejection ratio (CMRR) of 120 dB at 60 Hz.

-

Rugged Design

- IP65-rated enclosure withstands dust, humidity, and vibration in industrial settings.

- MTBF of 150,000 hours (per GE’s reliability testing).

-

Modular Flexibility

- Hot-swap capability allows module replacement without system shutdown.

- Supports up to 32 modules per control rack for large-scale installations.

Industry-Specific Applications:

- Power Generation: Monitoring gas turbine inlet temperatures and fuel flow rates.

- Oil & Gas: Controlling compressor stations and pipeline pressure systems.

- Water Management: Regulating pump speeds based on level sensor inputs.

Case Study:

A Middle Eastern power plant reduced maintenance costs by 18% using the IS200STAOH2AAA to monitor 96 gas turbine sensors. The module’s self-diagnostic features (e.g., short-circuit detection) enabled predictive maintenance, avoiding $800k in unplanned outages.

IS200STAOH2AAA

- Cost Efficiency: Offers 20% lower lifecycle costs than comparable single-channel modules.

- Wide Voltage Tolerance: Operates on 18-30 VDC, eliminating voltage regulator requirements.

- Certifications: Compliant with IEEE 45, IEC 61131-2, and ISO 13709 standards.

-

Channel Requirements:

- For higher channel density, consider the IS200STAHH2 (16-channel variant).

- Verify sensor compatibility (e.g., 4-20 mA vs. 0-10 V) with existing systems.

-

Environmental Conditions:

- Choose the IS200STAOH2AAAR variant for radiation-hardened environments (e.g., nuclear plants).

- Ensure proper cooling in high-temperature installations (≥50°C).

-

Budget Considerations:

- Refurbished units (2-year warranty) are available at 40% discount compared to new modules.

- For HART communication support, upgrade to the IS200STAOH2AAAH model.

-

Installation:

- Use shielded cables and proper grounding to minimize noise.

- Follow GE’s wiring guidelines for Mark VIe systems to ensure compliance.

-

Calibration:

- Factory-calibrated offsets provide ±0.03% accuracy without field adjustment.

- Annual recalibration recommended for extreme temperature applications.

-

Safety:

- Power down the system before module replacement.

- Adhere to NEC Article 430 for motor control center installations.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

GE IS200STAOH2AAA and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide