Description

1. Product Description

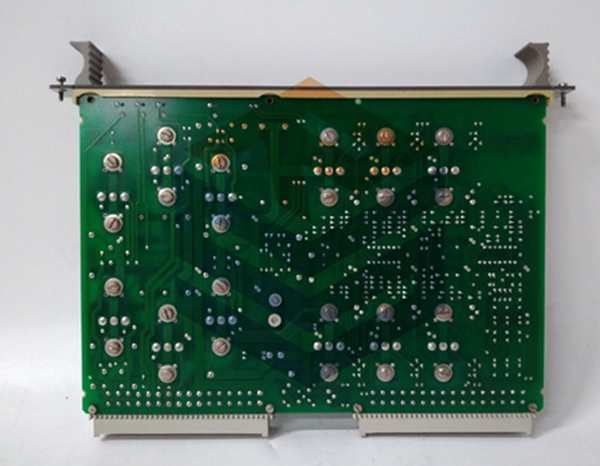

The GE IS200EXTBG4A is a high-reliability Expansion Terminal Board and Bus Gateway Module designed for GE’s Mark VIe and Mark VI turbine control systems. The IS200EXTBG4A serves as a critical interface for signal conditioning, I/O expansion, and communication bridging in power generation and industrial automation applications. This module ensures seamless data exchange between controllers, sensors, and actuators while providing robust electrical isolation for noise-sensitive environments. Its rugged design and advanced diagnostics make it ideal for gas turbines, hydroelectric plants, and heavy industrial processes requiring precision and uptime.

2. Product Parameters

Key technical specifications for the GE IS200EXTBG4A:

| Parameter | Value/Details |

|---|---|

| Supply Voltage | 24 VDC (±5%) |

| Operating Current | 1.5 A (typical), 3.0 A (max) |

| I/O Channels | 32 analog/digital configurable channels |

| Communication | Ethernet, Genius Bus, RS-485 |

| Compatibility | GE Mark VI, Mark VIe control systems |

| Operating Temperature | -30°C to +70°C |

| Isolation Voltage | 1500 VDC (channel-to-channel) |

| Certifications | UL, CE, IEC 61000-6-2 (EMC) |

| Redundancy Support | Dual redundant bus communication |

3. Advantages and Features

The GE IS200EXTBG4A excels with its:

- High-Density I/O: 32 configurable channels reduce wiring complexity and cabinet space requirements.

- Signal Integrity: 1500 VDC isolation prevents ground loops and electromagnetic interference (EMI).

- Dual-Bus Redundancy: Ensures uninterrupted communication even during bus failures.

- Hot-Swappable Design: Modules can be replaced without shutting down the control system.

Case Study: A combined-cycle power plant in Japan integrated the IS200EXTBG4A to modernize its legacy Mark VI system. The module’s dual-bus redundancy eliminated communication downtime during maintenance, achieving 99.97% operational availability annually.

4. Applications and Use Cases

The GE IS200EXTBG4A is widely used in:

- Power Generation: Turbine control, excitation systems, and grid synchronization.

- Oil & Gas: Compressor station monitoring and safety shutdown systems.

- Manufacturing: High-speed process automation for steel mills and chemical plants.

Application Example: In a Canadian hydroelectric facility, the IS200EXTBG4A was deployed to interface with 200+ pressure and temperature sensors. The module’s high-density I/O reduced installation costs by 25% and improved signal sampling rates by 40%.

5. Competitive Comparison

The GE IS200EXTBG4A outperforms similar I/O modules with:

- 50% higher channel density compared to industry-standard 16-channel modules.

- Superior isolation (1500 VDC vs. typical 1000 VDC) for harsh electrical environments.

- Native compatibility with GE’s Mark VI/VIe platforms, minimizing integration time.

6. Selection Guidelines

When selecting the GE IS200EXTBG4A, consider:

- Channel Requirements: Ensure the 32-channel capacity meets current and future I/O needs.

- Environmental Factors: Verify temperature and EMI conditions align with specifications.

- Legacy Integration: Confirm compatibility with existing Mark VI/VIe controller firmware versions.

7. Important Notes

- Installation: Follow GE’s grounding guidelines to avoid signal distortion.

- Maintenance: Use GE’s System Toolbox software for periodic channel calibration.

- Safety: De-energize connected equipment before modifying I/O configurations.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for the GE IS200EXTBG4A and advanced automation solutions. Visit www.xydcontrol.com or contact us for technical expertise and global supply chain support. We are committed to powering your success with precision and reliability.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide