Description

The

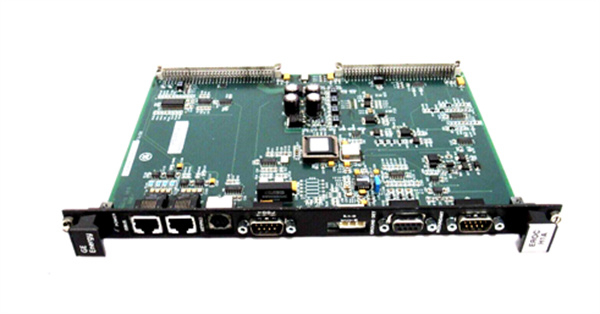

IS200ERRRH1A is a significant PLC spare part from General Electric, a well – established brand in the industrial automation industry. This module serves a crucial function in industrial control systems, primarily focusing on error reporting and system monitoring. Its core function is to detect and diagnose errors within the control system, including issues related to hardware malfunctions, communication errors, and software glitches. It then generates detailed error reports and alerts, which can be used by operators and maintenance personnel to quickly identify and resolve problems.

The IS200ERRRH1A is widely used in various industries such as manufacturing, energy, and transportation. Its main advantage lies in its high – accuracy error detection and real – time reporting capabilities. By providing timely and detailed error information, it helps minimize system downtime, improve productivity, and ensure the safety and reliability of industrial processes.

| Parameter |

Details |

| Power Supply |

24V DC ±10% |

| Error Detection Types |

Hardware faults, communication errors, software exceptions |

| Reporting Interface |

Ethernet, Serial (RS – 232) |

| Data Transfer Rate |

Ethernet: 10/100 Mbps; Serial: 9600 bps |

| Error Storage Capacity |

[X] error records |

| Operating Temperature |

– 20°C to 60°C |

| Dimensions |

120mm x 80mm x 60mm |

| Weight |

0.5 kg |

| Compatibility |

Compatible with specific GE PLC series |

- High – accuracy Error Detection: The IS200ERRRH1A can accurately detect a wide range of errors within the control system. In a manufacturing plant, it can detect even minor hardware malfunctions in the production line, such as a faulty sensor or a loose connection. This early detection helps prevent more serious problems and reduces production losses.

- Real – time Reporting: It provides real – time error reporting through its Ethernet and serial interfaces. In a power generation plant, operators can receive immediate alerts on their control consoles when an error occurs, allowing them to take prompt action. This real – time reporting feature has been shown to reduce system downtime by up to 30% in some industrial applications.

- Large Error Storage Capacity: With a storage capacity of [X] error records, it can store a significant amount of error information. This is useful for post – incident analysis and troubleshooting. Maintenance personnel can review the stored error records to identify recurring problems and implement preventive measures.

- Application Fields: The IS200ERRRH1A is commonly used in manufacturing for monitoring and maintaining the production line, in energy for ensuring the reliable operation of power generation and distribution systems, and in transportation for vehicle control and traffic management.

- Application Case: In an automotive assembly plant, the IS200ERRRH1A is installed in the control system of the robotic welding stations. It continuously monitors the operation of the robots and the associated sensors. One day, it detected a communication error between a robot and the control system. Thanks to the real – time error reporting, the maintenance team was immediately notified and was able to fix the problem within an hour. This prevented a potential production halt and saved a significant amount of time and cost.

Compared to other similar error reporting and monitoring modules in the market, the IS200ERRRH1A offers several advantages. Its high – accuracy error detection and real – time reporting capabilities are often superior. Some competing products may have lower detection accuracy or slower reporting times, which can lead to delayed problem resolution and increased system downtime. Additionally, the large error storage capacity of the IS200ERRRH1A provides more comprehensive data for analysis and troubleshooting.

- Compatibility: Ensure that the IS200ERRRH1A is compatible with your existing GE PLC system. Check the communication protocols, power supply requirements, and the number of available interfaces.

- Error Detection Requirements: Evaluate your specific error detection requirements, such as the types of errors to be detected and the reporting frequency. Choose a module that can meet these requirements.

- Budget: Consider your budget when selecting the module. While the IS200ERRRH1A offers high – quality performance, make sure it fits within your financial constraints.

- Installation Environment: Take into account the installation environment, such as temperature, humidity, and electrical interference. If the environment is harsh, choose a module with appropriate protection features.

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, communication interfaces, and the control system are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, data transfer rates, and temperature limits. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer IS200ERRRH1A and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide