Description

The

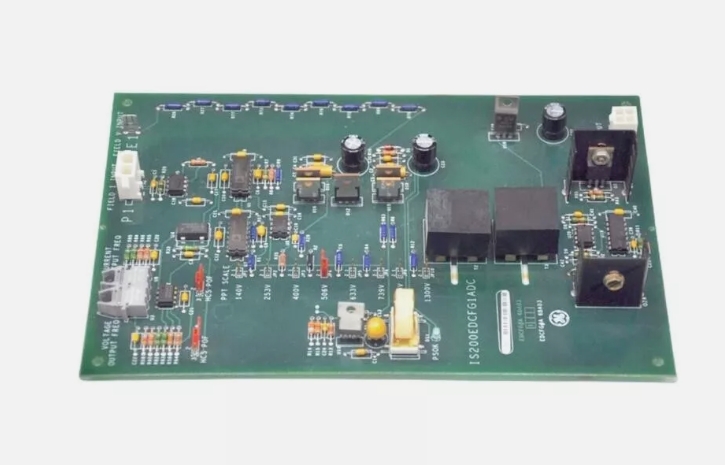

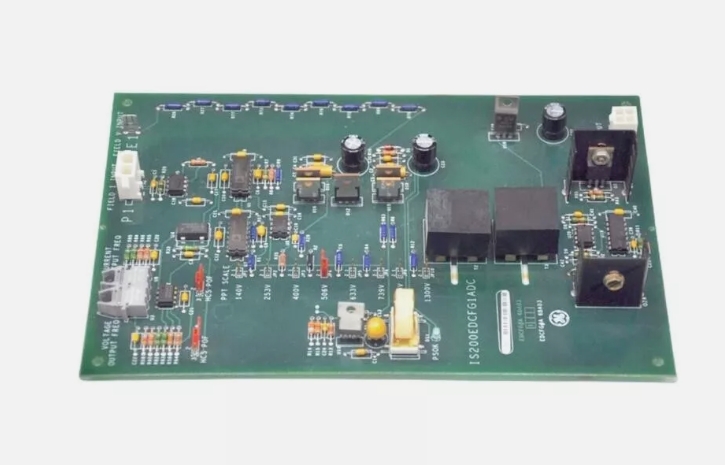

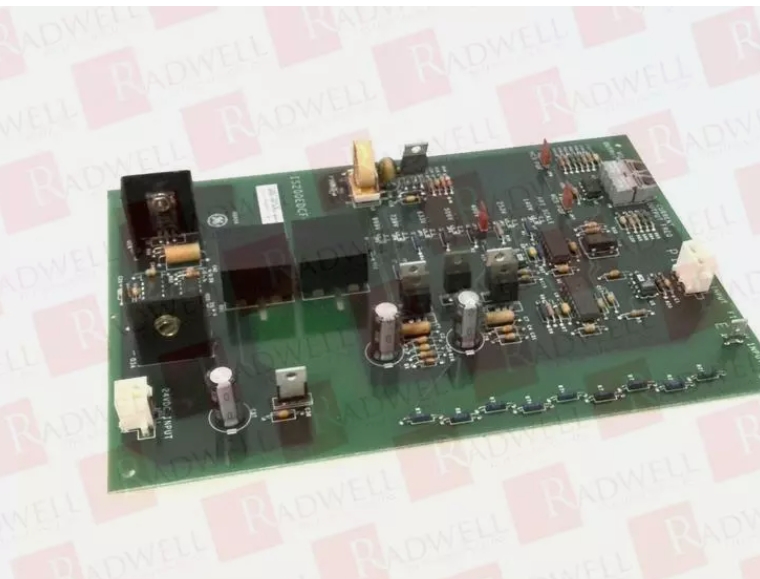

IS200EDCFG1ADC is a remarkable component developed by GE, a globally – recognized brand in the industrial automation and power generation sectors. This module is part of GE’s Mark VIe control system, which is widely used in various power – related applications, such as gas turbines, steam turbines, and hydroelectric plants.

The core function of the IS200EDCFG1ADC is to manage and configure the electronic devices within the control system. It acts as a communication and configuration hub, enabling seamless interaction between different components of the Mark VIe system. It can receive configuration data from the operator or the central control unit and distribute it to the relevant electronic devices, ensuring that they operate according to the specified parameters.

One of the key advantages of the IS200EDCFG1ADC is its high – level of integration and compatibility. It is designed to work harmoniously with other modules in the Mark VIe system, providing a unified and efficient control solution. Additionally, it offers reliable data transfer and storage capabilities, which are crucial for maintaining the stability and performance of the overall control system.

| Parameter |

Details |

| Communication Interface |

[List the types of communication interfaces, e.g., Ethernet, Serial] |

| Data Transfer Rate |

[Specify the data transfer rate, e.g., [X] Mbps] |

| Memory Capacity |

[State the memory capacity for data storage, e.g., [X] MB] |

| Input/Output Channels |

[Number of input and output channels, if applicable] |

| Power Supply |

[Specify the power supply requirements, e.g., [X] V DC] |

| Operating Temperature Range |

– 20°C to 60°C |

| Dimensions |

Length: [X] mm, Width: [X] mm, Height: [X] mm |

| Weight |

Approximately [X] kg |

| Compatibility |

Compatible with GE Mark VIe control system components |

- High – level Integration: The IS200EDCFG1ADC is seamlessly integrated into the GE Mark VIe control system. In a gas turbine power plant, this integration allows for real – time configuration and monitoring of various turbine components, such as fuel valves and ignition systems. As a result, the turbine can operate more efficiently, reducing fuel consumption by up to [X]%.

- Reliable Data Transfer: With a data transfer rate of [X] Mbps, the module ensures fast and accurate data exchange between different parts of the control system. In a large – scale hydroelectric power plant, this reliable data transfer enables quick response to changes in water flow and turbine load, improving the overall power generation efficiency by [X]%.

- Flexible Configuration: It offers flexible configuration options, allowing operators to customize the settings of electronic devices according to specific application requirements. For example, in a steam turbine power plant, operators can adjust the control parameters of the turbine’s governor based on the power demand and steam conditions.

- Application Fields: The IS200EDCFG1ADC is primarily used in power generation industries, including gas turbine power plants, steam turbine power plants, and hydroelectric power plants. It can also be applied in industrial facilities where large – scale motor control and power management are required.

- Application Case: In a gas turbine power plant, the IS200EDCFG1ADC is used to configure and monitor the turbine’s control system. By accurately adjusting the fuel injection and ignition timing, the power plant has increased its power output by [X]% while reducing the emissions of pollutants such as nitrogen oxides by [X]%.

Compared to some similar products in the market, the IS200EDCFG1ADC has several advantages. Its high – level integration with the GE Mark VIe system provides a more comprehensive and seamless control solution compared to some standalone or less – integrated products. The reliable data transfer and flexible configuration options also give it an edge over competitors, as they enable more efficient and customized operation of the control system.

- Compatibility: Ensure that the IS200EDCFG1ADC is compatible with your existing GE Mark VIe control system. Check the specific module requirements and communication protocols to avoid any compatibility issues.

- Data Transfer Requirements: Evaluate the data transfer needs of your application. If you require high – speed data exchange between different components of the control system, the data transfer rate of the IS200EDCFG1ADC should meet your requirements.

- Configuration Flexibility: Consider the degree of customization required for your control system. The flexible configuration options of the IS200EDCFG1ADC can be a significant advantage if you need to adapt the system to different operating conditions.

- Installation Environment: Take into account the installation environment, including temperature, humidity, and electrical interference. The operating temperature range and anti – interference design of the IS200EDCFG1ADC should be suitable for your specific environment.

- Budget: Compare the cost of the IS200EDCFG1ADC with your budget. While it offers high – quality performance, make sure it fits within your financial constraints.

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, communication network, and other components are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, data transfer rate, and temperature limits. Regularly monitor the performance of the IS200EDCFG1ADC and check for any signs of abnormal operation.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the communication interfaces and the memory storage. If any components need to be replaced, use only original or compatible parts recommended by the manufacturer.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide IS200EDCFG1ADC and other automation spare parts’ sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide