Description

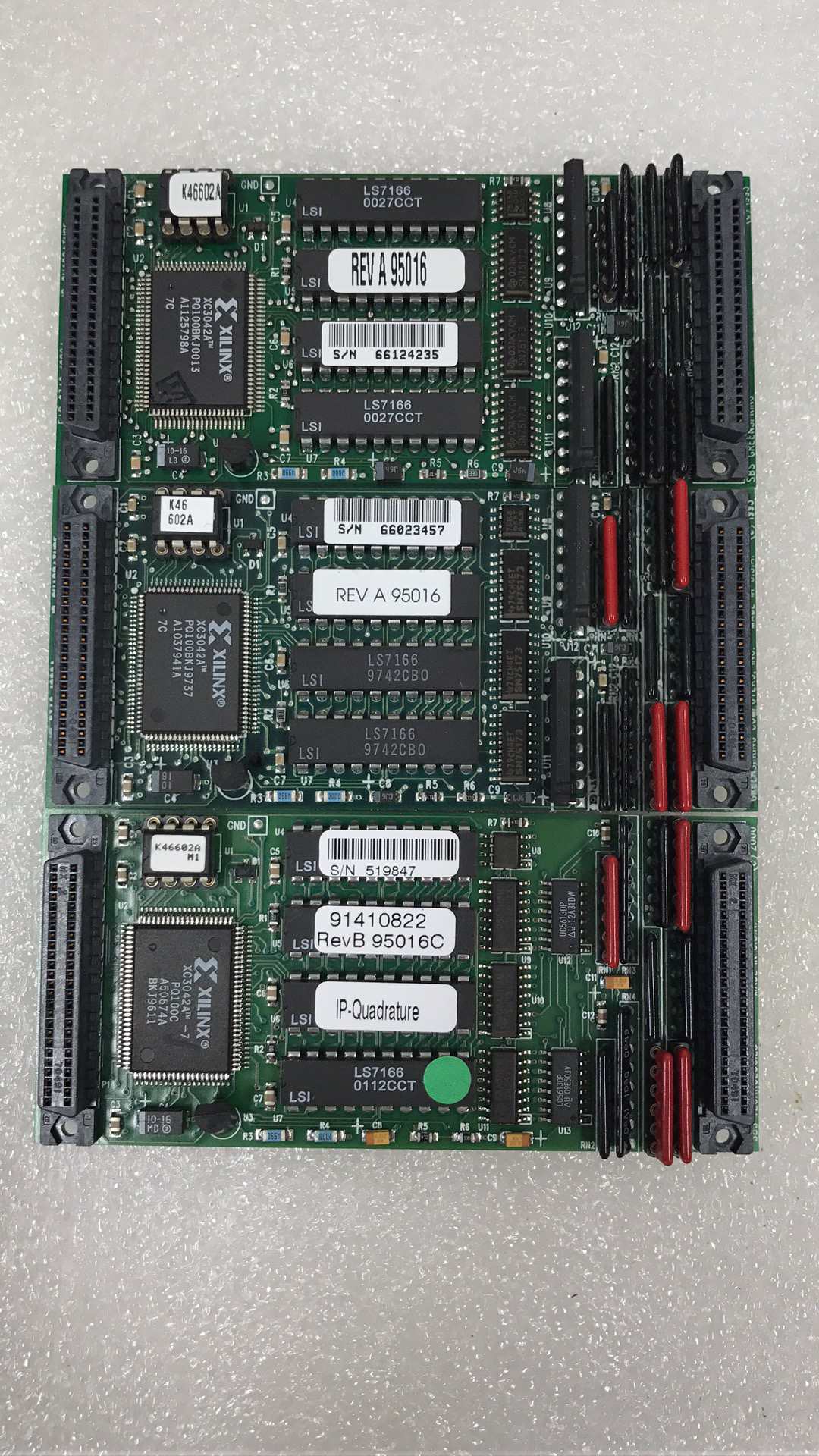

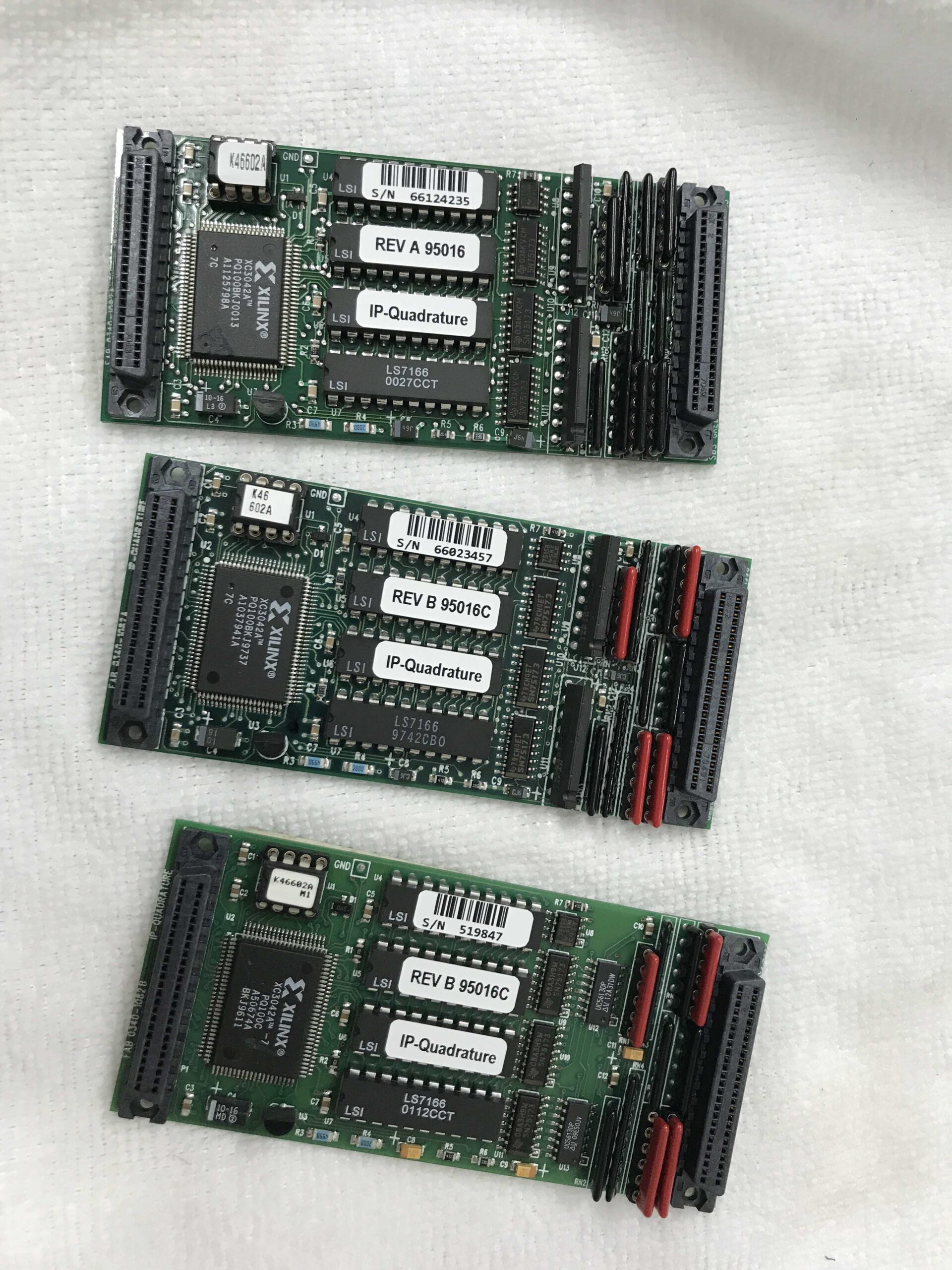

Product Description

The term “IP-QUADRATURE” is not a typical and widely known specific PLC spare part model from the common brands mentioned. However, in the context of PLC automation, a quadrature encoder interface (which might be related to “IP-QUADRATURE” in a more general sense) is often used. Let’s assume “IP-QUADRATURE” refers to a quadrature encoder interface module.

An IP-QUADRATURE module is a crucial component in PLC automation systems. It is designed to receive and process signals from quadrature encoders, which are widely used to measure position, speed, and direction in various industrial applications. The IP-QUADRATURE module decodes the quadrature signals (usually two square waves with a 90-degree phase difference) from the encoder and converts them into a format that can be easily processed by the PLC. This allows the PLC to accurately determine the position and movement of mechanical components such as motors, conveyor belts, and robotic arms.

One of the key advantages of the IP-QUADRATURE module is its ability to provide precise and reliable position feedback. By accurately decoding the quadrature signals, it enables the PLC to control the motion of equipment with high precision, improving the overall efficiency and quality of industrial processes. Additionally, it is often designed to be compatible with a wide range of quadrature encoders, making it a flexible choice for different automation setups.

Product Parameters

| Parameter | Details |

|---|---|

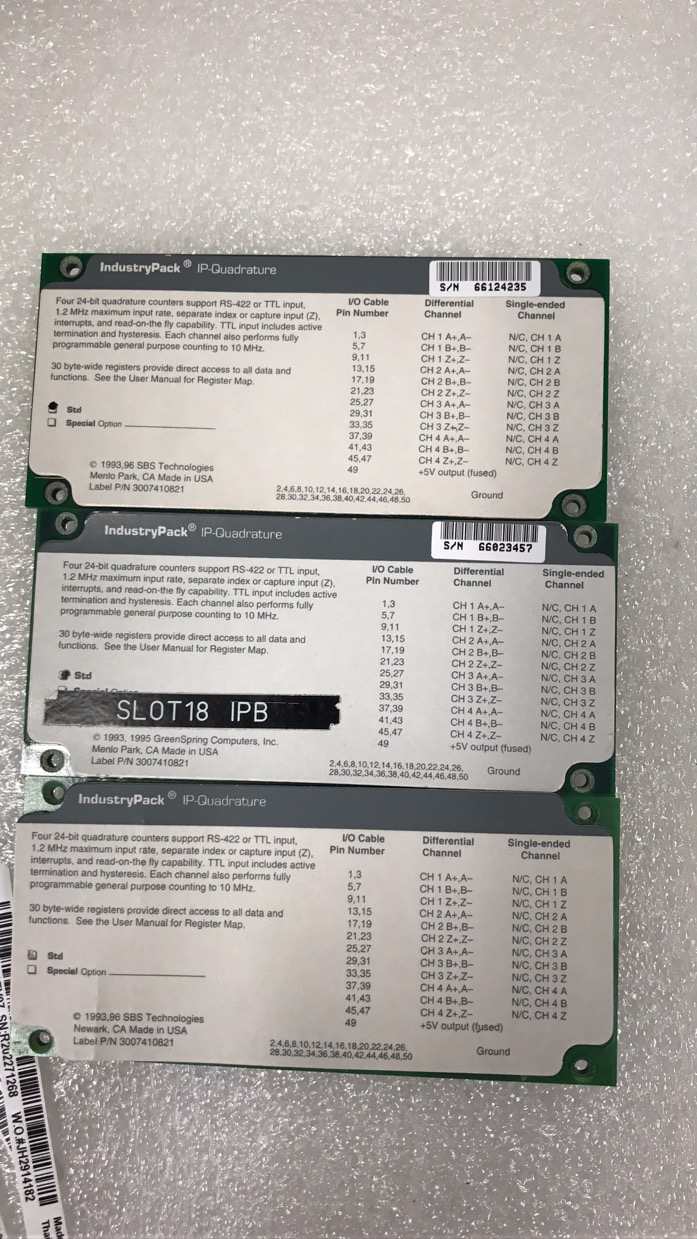

| Input Signal Type | Quadrature signals (A and B channels with 90-degree phase difference, and often a Z index channel) |

| Input Voltage Range | Typically 5V to 24V DC (varies depending on the specific module) |

| Frequency Response | Can handle frequencies up to several kHz (e.g., 10 kHz to 50 kHz depending on the model) |

| Compatibility | Compatible with most standard quadrature encoders; may also be compatible with different PLC brands and models depending on the communication interface |

| Communication Interface | May support interfaces such as RS-485, Ethernet (e.g., Modbus TCP over Ethernet for some advanced models), or direct connection to the PLC’s internal bus |

| Isolation | Some models may offer electrical isolation between the encoder input and the PLC to prevent electrical interference, usually with an isolation voltage of 500V to 1500V AC |

Advantages and Features

- High Precision: The IP-QUADRATURE module can achieve very high precision in position measurement. For example, in a CNC machine application, it can accurately detect the position of the cutting tool with a resolution of up to 0.001 mm, ensuring the production of high-quality parts.

- Wide Compatibility: It is designed to work with a variety of quadrature encoders, regardless of the brand or specific model. This flexibility allows engineers to choose the most suitable encoder for their application and still use the same IP-QUADRATURE module. In a large-scale manufacturing plant, where different types of encoders are used on various production lines, this compatibility feature simplifies the automation system design and reduces costs.

- Reliable Operation: With features like electrical isolation and a wide input voltage range, the IP-QUADRATURE module can operate reliably in harsh industrial environments. It can withstand electrical noise, voltage fluctuations, and temperature variations, ensuring continuous and accurate position feedback.

Application Areas and Application Cases

- Application Areas: The IP-QUADRATURE module is widely used in industries such as manufacturing (e.g., automotive manufacturing, electronics manufacturing), robotics, packaging, and material handling. In manufacturing, it is used to control the movement of assembly robots, conveyor belts, and machine tools. In robotics, it helps in precisely positioning the robotic arms for tasks such as pick-and-place operations. In packaging, it is used to control the movement of packaging machinery to ensure accurate product placement and packaging.

- Application Case: In an automotive assembly plant, the IP-QUADRATURE module is used to control the movement of the conveyor belts that transport car parts. The module receives signals from quadrature encoders installed on the conveyor belt motors. By accurately measuring the speed and position of the conveyor belts, the PLC can ensure that the car parts are delivered to the correct assembly stations at the right time. This has significantly improved the efficiency of the assembly process and reduced errors in part placement.

Competitor Comparison

Compared to some similar quadrature encoder interface modules in the market, the IP-QUADRATURE module stands out in terms of its wide compatibility and high precision. Some competing products may have limited compatibility with certain encoder brands or models, which can restrict the flexibility of the automation system. In contrast, the IP-QUADRATURE module can work with a broader range of encoders. Additionally, its high precision in position measurement, as demonstrated by its ability to achieve a resolution of up to 0.001 mm in some applications, surpasses the performance of some other modules that may have lower resolution capabilities.

Selection Recommendations

- Compatibility: When selecting the IP-QUADRATURE module, ensure that it is compatible with the quadrature encoders you plan to use. Check the input signal specifications, voltage range, and communication interface to ensure seamless integration. Also, make sure it is compatible with your PLC system, considering factors such as the PLC’s communication protocol and input/output requirements.

- Performance Requirements: Consider the specific performance requirements of your application. If you need high precision in position measurement, look for a module with a high resolution and a wide frequency response. If your application involves high-speed operation, ensure that the module can handle the required encoder frequencies.

- Budget: While the IP-QUADRATURE module offers high performance and flexibility, it is important to consider your budget. Compare the prices of different models and suppliers, but also take into account the long-term benefits such as reliability and compatibility. Sometimes, investing in a slightly more expensive but more reliable module can save costs in the long run due to reduced maintenance and downtime.

Precautions

- Installation: When installing the IP-QUADRATURE module, follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Connect the encoder wires correctly, making sure to match the A, B, and Z channels to the corresponding inputs on the module. Also, check the polarity of the power supply to avoid damaging the module.

- Maintenance: Regularly check the operation of the IP-QUADRATURE module. Monitor the input signals from the encoder to ensure they are within the normal range. If there are any signs of abnormal operation, such as incorrect position readings or communication errors, troubleshoot the problem immediately. Clean the module periodically to remove dust and debris that may affect its performance.

- Safety: When working with the IP-QUADRATURE module and associated equipment, follow all safety regulations. Wear appropriate protective gear, especially when working with electrical components. Avoid touching the module or its connections while the power is on to prevent electrical shock.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide the sales and technical support for IP-QUADRATURE and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components