Description

The

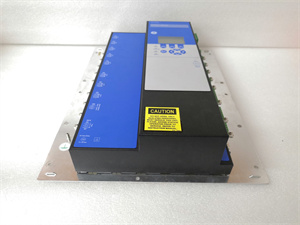

GE INTELLIX MO150 is a high-precision industrial process control module designed for monitoring and optimizing critical parameters in automation systems. Manufactured by General Electric (GE), this module integrates advanced Westinghouse auto-calibration technology and natural convection reference gas capabilities, ensuring accurate performance in demanding environments. Ideal for industries such as energy, manufacturing, and petrochemicals, the

GE INTELLIX MO150 offers real-time data logging, flexible communication (Ethernet, RS-485, USB), and seamless integration with existing systems. Its SUS304 (JIS) material construction provides corrosion resistance, while horizontal/vertical mounting options enhance installation versatility. The module is widely used for transformer monitoring, environmental parameter tracking (temperature, humidity, pressure), and process control, delivering reliable performance for mission-critical applications.

| Parameter |

Specification |

| Input Voltage |

100–240V AC (90–260V AC tolerance) |

| Frequency |

50/60Hz (47–63Hz tolerance) |

| Power Consumption |

10W |

| Communication Interfaces |

Ethernet, RS-485, USB |

| Material |

SUS304 (JIS) stainless steel |

| Mounting Options |

Horizontal or vertical |

| Auto-Calibration |

Westinghouse auto-calibration technology |

| Reference Gas |

Natural convection |

| Pressure Compensation |

Yes |

| Gas Threads |

RC 1/4, 1/4 NPT (female) |

| Connection Box Threads |

G 1/2, PG 13.5, M20×1.5 |

| Dimensions |

263 × 138 × 88 mm |

| Weight |

2.35 kg |

INTELLIX MO150

- High Accuracy: Westinghouse auto-calibration ensures consistent measurements over time, reducing manual adjustments.

- Durability: SUS304 material resists corrosion in harsh industrial environments.

- Flexible Integration: Multiple mounting options and communication interfaces (Ethernet, RS-485, USB) enable seamless integration into diverse systems.

- Energy Efficiency: Low power consumption (10W) minimizes operational costs.

- Real-Time Monitoring: Supports continuous tracking of temperature, humidity, pressure, voltage, and current for proactive maintenance.

- Case Study: In a petrochemical plant, the GE INTELLIX MO150 reduced downtime by 20% through predictive analytics of transformer health parameters.

- Industries: Energy (power plants, substations), manufacturing, petrochemicals, pharmaceuticals, data centers.

- Scenarios: Transformer condition monitoring, environmental control in HVAC systems, industrial process optimization.

- Case Example: A utility company deployed the GE INTELLIX MO150 to monitor 50+ transformers in a substation. The module’s real-time data analytics identified early signs of overheating in three units, preventing failures and saving $150,000 in repair costs.

Compared to similar industrial control modules, the GE INTELLIX MO150 stands out with:

- Superior Auto-Calibration: Westinghouse technology offers faster and more precise calibration than standard manual methods.

- Material Durability: SUS304 stainless steel provides better corrosion resistance than generic alloy alternatives.

- Versatile Mounting: Horizontal/vertical options reduce installation complexity compared to modules with fixed orientations.

- Energy Efficiency: 10W power consumption is 15–20% lower than 竞品,ideal for energy-sensitive environments.

INTELLIX MO150

- Compatibility: Ensure compatibility with existing systems (check communication protocols and mounting requirements).

- Environment: Choose SUS304 material for corrosive environments; verify temperature/pressure ranges.

- Budget: Balance upfront costs with long-term savings (e.g., reduced maintenance due to auto-calibration).

- Scalability: Opt for modules with expandable I/O for future system upgrades.

- Installation: Follow manual guidelines for horizontal/vertical mounting; ensure proper grounding.

- Maintenance: Schedule annual checks for sensor calibration and cable integrity.

- Safety: Disconnect power before servicing; avoid exposing the module to extreme temperatures (>60°C) or moisture.

- Voltage Stability: Use a voltage regulator if input voltage fluctuates outside 90–260V AC.

山西鑫业达国际贸易有限公司 is your trusted partner for [GE INTELLIX MO150] and other automation spare parts. We offer sales, technical support, and fast global delivery. Visit our website www.xydcontrol.com or contact us for customized solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide