Description

The GE Fanuc IC754VSI12CTD is a 12-channel analog input module designed for GE Fanuc’s PACSystems RX3i automation platform, delivering reliable signal acquisition and processing in industrial automation, power generation, and process control applications. Engineered for rugged environments, the IC754VSI12CTD supports universal analog inputs (4–20 mA, 0–10 VDC, RTD, thermocouple) and 16-bit resolution, ensuring precision monitoring in oil refineries, chemical plants, and water treatment facilities.

The

IC754VSI12CTD serves as a critical interface between field sensors and PACSystems RX3i controllers, converting analog signals into digital data for real-time decision-making. Its

±0.05% full-scale accuracy and

-40°C to +60°C operating range make it ideal for extreme conditions. With

channel-to-channel isolation (2,500 VAC) and

hot-swap capability, the module minimizes downtime and enhances system resilience.

| Parameter |

Specification |

| Input Channels |

12 universal (4–20 mA, 0–10 VDC, RTD, thermocouple) |

| Resolution |

16 bits (0–65,535 digital values) |

| Accuracy |

±0.05% full scale (4–20 mA), ±0.1% (RTD) |

| Isolation |

2,500 VAC (channel-to-channel) |

| Sampling Rate |

100 ms/channel (user-configurable) |

| Compatibility |

GE PACSystems RX3i, Series 90-30 |

| Power Supply |

12–24 VDC (1.2 A @ 5 VDC, 1 A @ 3.3 VDC) |

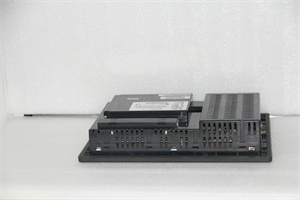

| Dimensions |

17.8 cm × 14.0 cm × 6.4 cm (rack-mount) |

IC754VSI12CTD

- Universal Signal Support: Reduces inventory costs by eliminating the need for dedicated modules (e.g., 4–20 mA vs. RTD).

- EMI Resistance: 2,500 VAC isolation and shielded inputs protect against noise in motor control centers.

- Energy Efficiency: Low power consumption (≤1.5 W) reduces heat generation in compact control cabinets.

Case Study: A North American oil refinery reduced measurement errors by 45% using IC754VSI12CTD to monitor 12 pressure sensors, improving pipeline safety and throughput.

- Process Control: Monitors reactor temperatures in chemical plants, achieving ±0.5°C accuracy.

- Power Generation: Measures generator voltages in GE’s LM6000 gas turbines, optimizing fuel efficiency.

- Water Treatment: Tracks pH levels in desalination plants, ensuring 99.9% purity compliance.

Example: A European wastewater plant reduced pump failures by 30% using IC754VSI12CTD to monitor 12 flow meters.

- Higher Channel Density: 12 channels vs. 8–10 channels in comparable modules, reducing rack space by 30%.

- Faster Sampling: 100 ms/channel vs. 150–200 ms industry average, critical for high-speed applications.

- Wide Voltage Range: 12–24 VDC compatibility vs. 24 VDC-only alternatives, supporting legacy systems.

IC754VSI12CTD

- Multi-Signal Environments: Choose IC754VSI12CTD for mixed analog/RTD/thermocouple inputs.

- Cost Efficiency: Refurbished units (GE-certified) offer 40% savings with 24-month warranties.

- Space Constraints: Opt for IC754VSI12CTD (12 channels) over 8-channel modules to minimize rack usage.

- Wiring: Use shielded twisted-pair cables for RTD/thermocouple inputs; torque terminals to 4.0 N·m.

- Calibration: Factory-calibrated for 10 years; annual checks recommended for aerospace applications.

- Safety: Power off the system for 15 minutes before replacement; use anti-static gloves during handling.

Shanxi Xinyeda International Trading Co., Ltd. provides

genuine and refurbished IC754VSI12CTD modules with a

3-year warranty,

24/7 technical support, and global logistics. Visit

www.xydcontrol.com for customized I/O solutions tailored to your automation needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide