Description

The

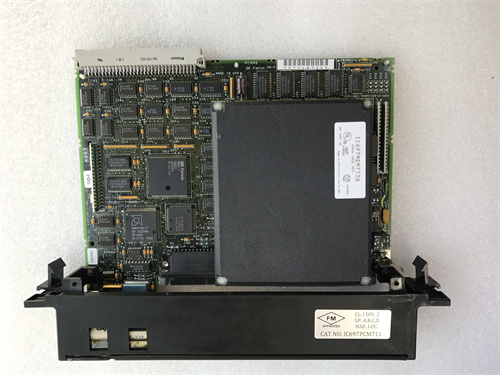

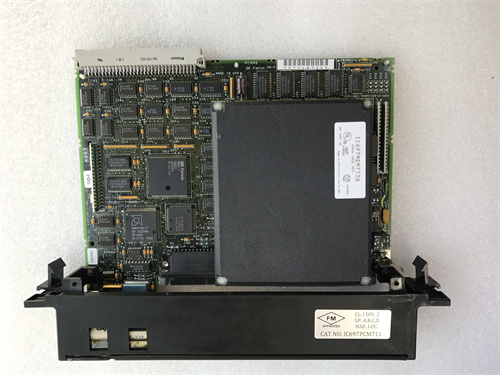

IC697PCM711P is a high-performance programmable logic controller (PLC) module that belongs to a specific series of industrial control products. It is designed to provide advanced control capabilities and functionality in various industrial automation applications. This module serves as a crucial component in automating and managing complex industrial processes, enabling efficient operation and precise control.

- Processor Performance: It is equipped with a powerful processor that can handle a large number of input and output signals, as well as execute complex control algorithms in a timely manner. The specific processing speed and capabilities are optimized to meet the demands of industrial applications with high data throughput and real-time control requirements.

- Memory Capacity: The IC697PCM711P typically has a significant amount of memory, including both program memory and data memory. This allows for the storage of extensive control programs and the handling of large amounts of data generated during the operation of industrial processes.

- Communication Interfaces: It features multiple communication interfaces, such as Ethernet, serial ports, and possibly other fieldbus interfaces like Profibus or DeviceNet. These interfaces enable seamless communication with other devices in the industrial network, including sensors, actuators, human-machine interfaces (HMIs), and other PLC modules.

- Input/Output Capabilities: The module is designed to support a variety of input and output signals. It can handle digital inputs and outputs, as well as analog inputs and outputs, depending on the specific configuration. The number of input and output channels may vary, but it is generally sufficient to meet the needs of medium to large-scale industrial control systems.

- Power Supply: Usually requires a stable DC power supply, typically in the range of 24 VDC. The power supply circuitry is designed to be efficient and reliable, ensuring stable operation of the module even in harsh industrial environments.

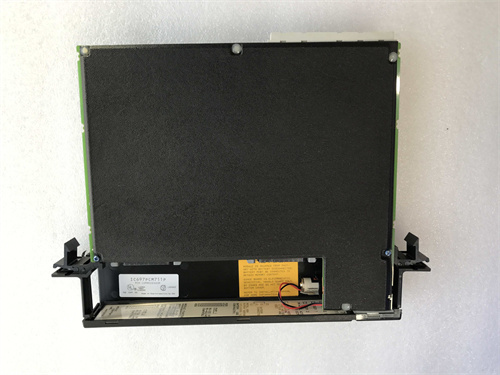

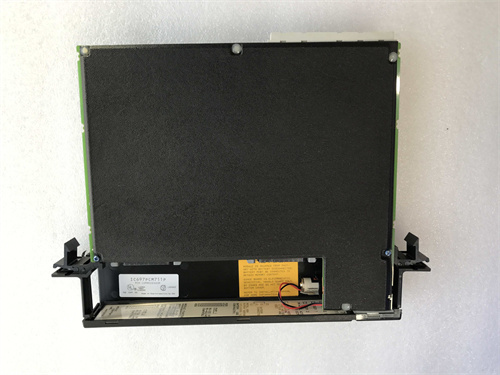

- High Reliability: Built with robust components and advanced manufacturing processes, the IC697PCM711P is designed to operate reliably in harsh industrial conditions. It has a high mean time between failures (MTBF) and is resistant to factors such as temperature variations, humidity, vibration, and electromagnetic interference.

- Scalability: This module offers excellent scalability, allowing for easy expansion of the control system as the needs of the industrial process grow. It can be easily integrated with other modules in the same series to increase the input/output capacity and functionality of the overall control system.

- Flexible Programming: Supports a variety of programming languages and techniques, such as ladder logic, function block diagram (FBD), and structured text (ST). This flexibility enables engineers to choose the programming method that best suits their skills and the specific requirements of the application.

- Advanced Diagnostics: The IC697PCM711P is equipped with advanced diagnostic capabilities. It can monitor its own operation status and detect faults in real-time. This helps in quickly identifying and resolving issues, reducing downtime and improving the overall efficiency of the industrial process.

- Automotive Manufacturing: In an automotive assembly plant, the IC697PCM711P can be used to control the production line, including the movement of robots, the operation of conveyor belts, and the quality inspection of parts. It ensures the smooth and efficient operation of the entire manufacturing process.

- Food and Beverage Industry: In a food processing factory, this module can be employed to control the temperature, pressure, and flow of ingredients in the production process. It helps in maintaining product quality and consistency, as well as optimizing the production efficiency.

- Chemical Processing: In a chemical plant, the IC697PCM711P is used to monitor and control complex chemical reactions, the operation of pumps and valves, and the safety systems. It plays a crucial role in ensuring the safety and efficiency of the chemical production process.

- Installation Environment: Choose an appropriate installation location for the IC697PCM711P, away from sources of strong electromagnetic interference and extreme environmental conditions. Ensure proper ventilation to prevent overheating.

- Wiring and Connection: Follow the correct wiring and connection procedures to ensure reliable communication and signal transmission. Use high-quality cables and connectors to minimize the risk of signal loss or interference.

- Software Configuration: Before using the module, carefully configure the software settings according to the specific requirements of the industrial process. This includes setting up input and output parameters, communication protocols, and control algorithms.

- Maintenance and Upgrades: Regularly perform maintenance on the IC697PCM711P, such as checking for software updates and hardware status. Keep spare parts on hand to quickly replace any faulty components and minimize downtime.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IC697PCM711P and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide