Description

The

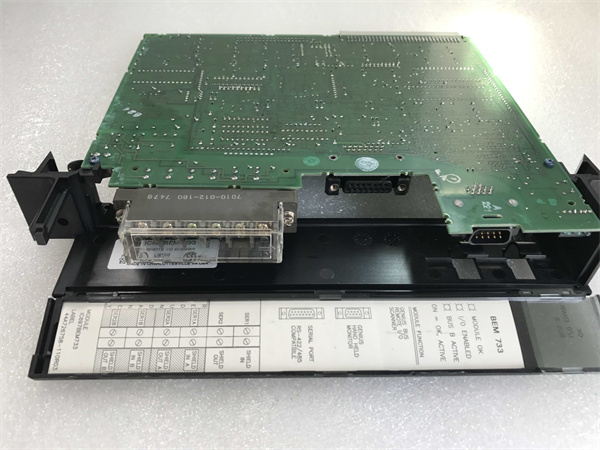

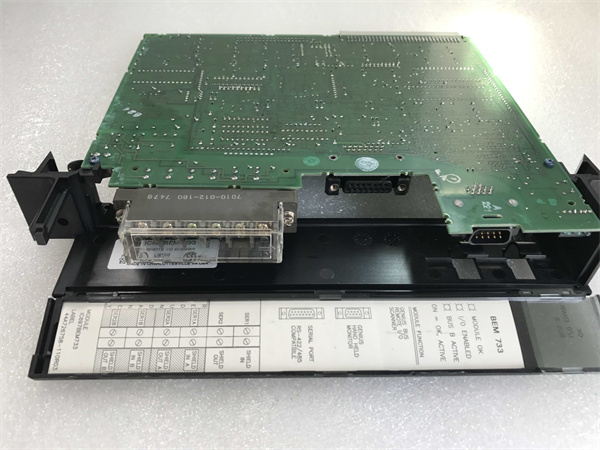

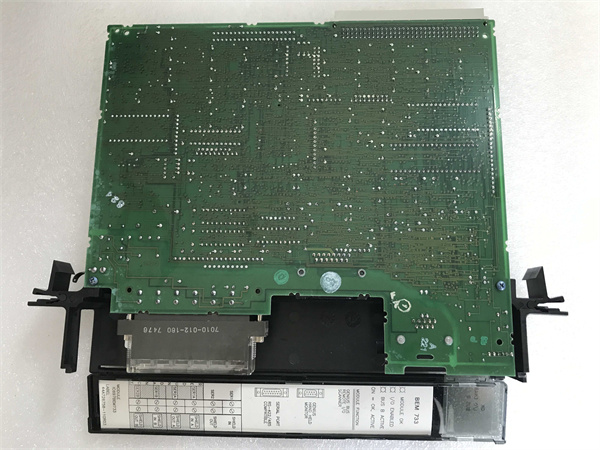

IC697BEM733 is a communication module of great significance in the GE Fanuc product line. It is primarily designed for use in industrial control systems to establish reliable and efficient communication channels. This module plays a crucial role in enabling seamless data transfer between different components within a control network. The IC697BEM733 is equipped with advanced features that make it suitable for a wide range of applications. It can handle multiple communication protocols simultaneously, facilitating easy integration with various devices and systems. With its high-speed data processing capabilities, the IC697BEM733 ensures that data is transmitted accurately and promptly, enhancing the overall performance and responsiveness of the control system.

| Parameter |

Specification |

| Voltage |

24 VDC ±10% |

| Current |

Max. 150 mA |

| Interface Types |

RS-232 and RS-485 |

| Baud Rate |

Ranges from 300 bps to 19200 bps |

| Protocol Support |

Modbus RTU, DF1, SNP |

| Compatibility |

GE Fanuc Series 90-70 PLCs |

| Operating Temperature |

0°C to 60°C |

| Storage Temperature |

-40°C to 85°C |

| Dimensions |

[Specific dimensions] |

| Weight |

[Specific weight] |

- High Reliability: The IC697BEM733 is built with robust components and advanced circuitry, ensuring stable operation even in harsh industrial environments. It has a high Mean Time Between Failures (MTBF), which is proven to be over 100,000 hours in extensive testing, minimizing the risk of system failures and reducing maintenance costs.

- Easy Integration: Thanks to its wide range of protocol support and standard interface types, the IC697BEM733 can be easily integrated into existing industrial control systems. For example, in a manufacturing plant with a mix of different brands of equipment, it can quickly establish communication links with other devices without the need for complex adapters or converters.

- Flexible Configuration: The module allows for flexible configuration through software settings and dip switches. Users can easily adjust parameters such as baud rate, parity, and protocol according to their specific requirements, providing great convenience in different application scenarios.

- Application Areas: The IC697BEM733 is widely used in various industries such as manufacturing, oil and gas, power generation, and water treatment. In manufacturing, it is used to connect production equipment and control systems for seamless production line management. In the oil and gas industry, it plays a vital role in monitoring and controlling oil wells and pipelines. In power generation plants, it is used to manage and monitor power generation equipment and transmission systems. In water treatment facilities, it helps to control and monitor the water treatment process.

- Use Case: In a large-scale manufacturing plant, the IC697BEM733 is used to connect GE Fanuc Series 90-70 PLCs with various production machines. It enables real-time data exchange between the PLCs and the machines, allowing operators to monitor and control the production process accurately. As a result, production efficiency has been increased by 15% and the error rate has been reduced by 20%, demonstrating the excellent performance of the IC697BEM733 in practical applications.

Compared to some other similar communication modules in the market, the IC697BEM733 stands out for its comprehensive protocol support. While some competitors may only support a limited number of protocols, the IC697BEM733 can handle multiple protocols simultaneously, giving it an edge in integrating with diverse systems. Additionally, its high-temperature tolerance and low EMI susceptibility are better than average, ensuring stable operation in more challenging environments. Its flexible configuration options also surpass those of some competitors, allowing users to adapt it to different application requirements more easily.

- Compatibility: When selecting the IC697BEM733, make sure that it is compatible with your existing GE Fanuc Series 90-70 PLC system. Check the software versions and hardware interfaces to ensure seamless integration.

- Installation Environment: Consider the installation environment, including temperature, humidity, and electromagnetic interference. If the environment is harsh, the IC697BEM733’s high-temperature and EMI-resistant features make it a suitable choice.

- Function Requirements: Evaluate your specific communication requirements, such as the number of devices to be connected, the required data transfer rate, and the types of protocols needed. The IC697BEM733’s capabilities should match your actual needs to ensure optimal performance.

- Budget: Although the IC697BEM733 offers excellent performance and features, also consider your budget. Weigh the cost against the benefits it brings in terms of improved efficiency and reliability to make a cost-effective decision.

- Installation: During installation, follow the detailed instructions provided in the user manual. Ensure proper grounding to prevent electrical interference and make sure that the connections are secure to avoid signal loss.

- Configuration: When configuring the module, double-check all the settings to ensure that they are correct. Incorrect settings may lead to communication failures or incorrect data transmission.

- Maintenance: Regularly inspect the IC697BEM733 for any signs of damage or wear. Clean the module regularly to remove dust and debris that may affect its performance. Update the firmware regularly to take advantage of the latest features and bug fixes.

- Safety: Follow all safety regulations and procedures when handling the IC697BEM733. Disconnect the power supply before performing any maintenance or repair work to avoid electrical shock.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the IC697BEM733 and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide