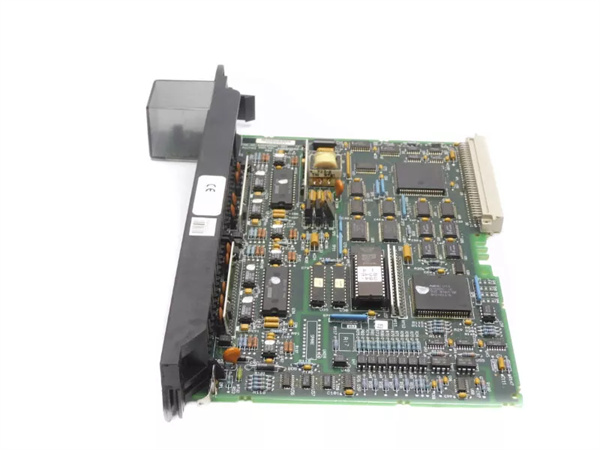

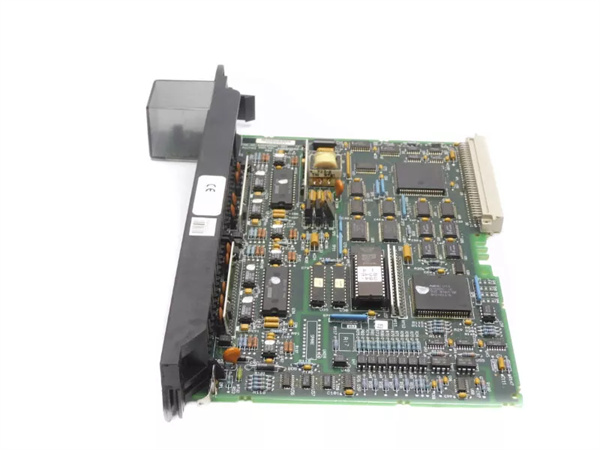

Description

The core function of the

IC697ALG320 lies in its high – precision analog processing ability. It can accurately convert analog signals into digital signals, which are then processed and analyzed by the PLC system. Whether it is for monitoring and controlling parameters such as temperature, pressure, and flow in industrial production processes or in complex automated production lines, the

IC697ALG320 plays a crucial role.

With its stable performance and reliable quality, the IC697ALG320 provides precise analog input and output solutions for various automation systems. One of its significant advantages is the availability of multiple signal input and output types, which allows it to flexibly adapt to different application scenarios. Moreover, it has excellent anti – interference capabilities, enabling it to operate stably in harsh industrial environments. Additionally, the IC697ALG320 supports seamless integration with PLC systems from multiple brands, greatly enhancing the compatibility and scalability of the system.

| Parameter |

Details |

| Voltage |

Typically 24VDC |

| Current |

Input channel current consumption is less than 50mA typically. Output channels can provide a certain driving current to meet the needs of regular loads. |

| Interface Types |

Standard analog input and output interfaces such as 4 – 20mA, 0 – 10V |

| Compatibility |

Compatible with multiple PLC series of brands like GE Fanuc |

| Resolution |

12 – bit or higher |

| Accuracy |

±0.1% FS (Full Scale) |

| Operating Temperature |

– 20°C to 60°C |

| Storage Temperature |

– 40°C to 85°C |

| Humidity |

5% – 95% non – condensing |

- High Reliability: The IC697ALG320 is designed with advanced circuit technology and uses high – quality electronic components. After strict quality inspections, its average Mean Time Between Failures (MTBF) exceeds 50,000 hours. In a steel mill with high – temperature and high – dust environments, the IC697ALG320 has been operating stably for over 4 years, ensuring the continuous and stable operation of the production process.

- Easy Integration: With standardized interfaces and communication protocols, the IC697ALG320 can be quickly and conveniently integrated into existing automation control systems. In an automation upgrade project of a food factory, integrating the IC697ALG320 only took 2 days, reducing the system integration time and cost significantly.

- High Precision: The 12 – bit or higher resolution and ±0.1% FS accuracy enable the IC697ALG320 to accurately collect and output analog signals, providing a guarantee for precise control. In a chemical production plant, the precise control of temperature and pressure using the IC697ALG320 has improved product quality by 15% and production efficiency by 12%.

- Application Areas

- Manufacturing: Used for the automation control of production lines, such as the control of robot movement and the speed and position control of material handling systems.

- Energy Industry: Applied in power plants and substations to monitor and control parameters such as voltage, current, and power.

- Water Treatment Industry: Used to monitor and control parameters such as water level, flow, and water quality, realizing the automation of the water treatment process.

- Application Case: In an automotive manufacturing plant’s painting workshop, the IC697ALG320 was used to control the flow and pressure of the spray guns of painting robots. By accurately collecting and processing analog signals, it achieved precise control of the painting thickness and uniformity. As a result, the quality and consistency of automotive painting were improved, while paint waste was reduced by 20%, and production costs were lowered.

Compared with similar products in the market, the IC697ALG320 has obvious advantages in terms of accuracy. Its ±0.1% FS accuracy is higher than that of some competing products. In terms of compatibility, it can be integrated with a wider range of PLC systems from different brands, providing users with more choices. Moreover, the IC697ALG320 has stronger anti – interference capabilities and can maintain stable performance in complex electromagnetic environments, while some similar products may experience signal fluctuations.

- Compatibility: Ensure that the selected IC697ALG320 is compatible with your existing PLC system, including aspects such as communication protocols and interface types.

- Installation Environment: Consider factors such as installation space, environmental temperature, humidity, and electromagnetic interference. If the installation environment is harsh, choose a model with a better protection level and stronger anti – interference ability.

- Budget: Make a reasonable selection based on your project budget. Although the IC697ALG320 offers high cost – effectiveness, also consider other related equipment and maintenance costs comprehensively.

- Function Requirements: Select the appropriate model according to the specific functional requirements of your actual application scenario, such as the number of analog channels needed, signal types, and accuracy requirements.

- Safety Specifications: During installation and use, strictly follow relevant electrical safety regulations to ensure the safety of operators.

- Correct Wiring: Carefully follow the instruction manual for wiring to ensure that the wiring of analog input and output signals is correct. Incorrect wiring may lead to equipment damage or system failures.

- Good Grounding: To improve anti – interference capabilities and the stability of the equipment, ensure that the equipment has a good ground connection.

- Regular Maintenance: Regularly check the operating status of the equipment, clean the surface of the device, and check if the connection wires are loose. Deal with potential problems in a timely manner.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide [IC697ALG320] and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide