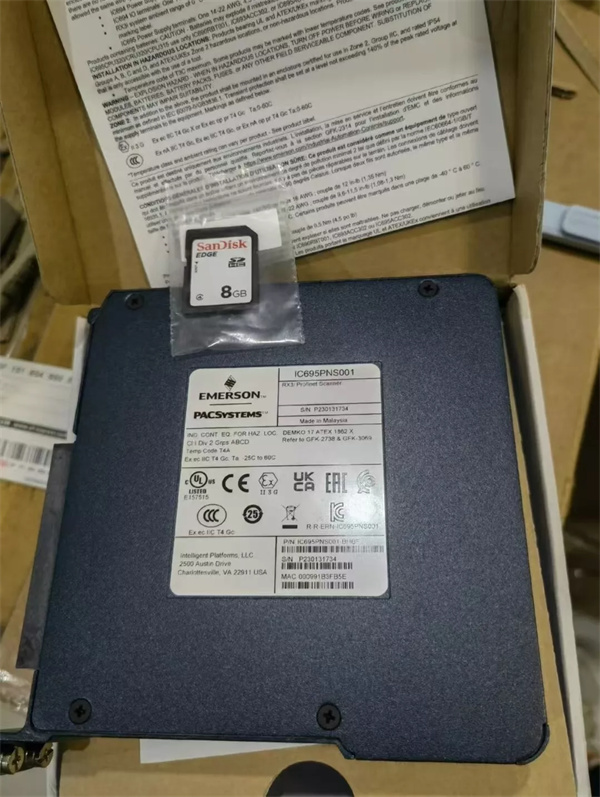

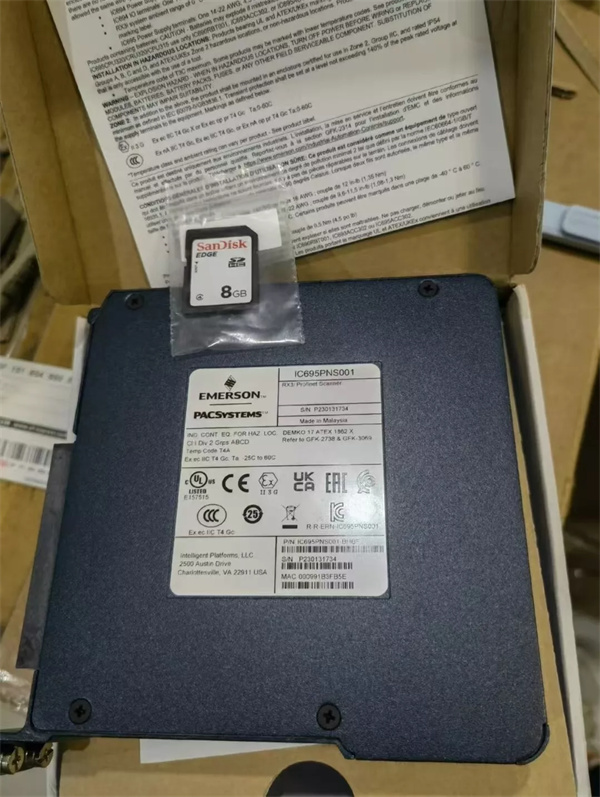

Description

IC695PNS001 is a PROFINET scanner module of the PACSystems RX3i product family under GE Fanuc/Emerson Automation. It is used to connect a remote I/O rack of Series 90-30 or RX3i modules to a PROFINET I/O network. It can send I/O data through the PROFINET network to the partner CPUs in the network and communicate with HMI, SCADA and other automation components. It has one micro USB port for firmware upgrade and four Ethernet ports that support 10/100/1000 Mbps transmission rate. The module has a simplified configuration method. Parameters such as I/O device name and IP address can be saved in an SD card and transferred to other PROFINET scanner modules.

- Protocol Support: PROFINET

- Ethernet Ports: 4 switched Ethernet ports, 2 RJ-45 connectors and 2 SFP cages

- USB Ports: 1 micro USB

- Internal Power: 1.2 A at 3.3 V DC; 1.1 A max at 5 V DC

- Status and Control Bits: 32 input status bits, 32 output control bits

- IP Address: 1 CIDR IP address

- MAC Addresses: 5 MAC addresses

- Required Software: Proficy Machine Edition 8.50 SIM 2 or later

- Operating Temperature: 0 to 60 degrees Celsius

- Storage Temperature: -40 to 85 degrees Celsius

- Supported Topologies: Linear, star, daisy chain, redundant media

- LED Indicators: OK LED, LAN LED, status LED, CONN LED, individual port LEDs, active LED, USB LED

- High Communication Speed: With four Ethernet ports supporting 10/100/1000 Mbps transmission rate, it can achieve high-speed data transmission, improving the efficiency of the entire control system.

- Easy Configuration: The parameter transfer function through the SD card simplifies the configuration process and reduces maintenance time. It can eliminate the dependence on software configuration tools.

- Comprehensive Monitoring: 8 LEDs with 22 patterns can provide users with operational error notifications, module status updates and identification cues.

- Hot Swap Capability: It allows for the replacement of modules during operation without shutting down the system, improving system availability and maintainability.

- Wide Temperature Range: With an operating temperature range of 0 to 60 degrees Celsius and a storage temperature range of -40 to 85 degrees Celsius, it can adapt to various harsh industrial environments.

- Application Areas: It is suitable for a variety of industries such as manufacturing, energy, and water treatment. In the manufacturing industry, it can be used in production lines to realize the connection and control of various intelligent devices; in the energy industry, it can be applied to power plants, oil and gas fields and other places to monitor and control equipment; in the water treatment industry, it can be used for the automation control of water treatment plants.

- Application Case: In a car manufacturing factory, IC695PNS001 is used to connect various PROFINET devices on the production line, such as robots, conveyors, and sensors, to the PLC control system. It realizes the real-time transmission of data between devices, enabling the coordinated operation of the entire production line and improving production efficiency and product quality.

Compared with some similar products in the market, IC695PNS001 has advantages in communication speed and configuration convenience. Its four high-speed Ethernet ports can better meet the needs of high-speed data transmission in modern industrial automation systems. The unique SD card parameter transfer function makes its configuration more convenient and fast, reducing the workload of technicians and shortening the system commissioning time. In addition, its wide temperature range and hot swap capability also make it more adaptable and reliable in complex industrial environments.

- Compatibility: Make sure that the selected IC695PNS001 is compatible with your existing PLC system, such as RX3i series CPUs like CPU315, CPU320, CPE305 and CPE310. Also, ensure that it is compatible with the software version, requiring Proficy Machine Edition 8.50 SIM 2 or later.

- Installation Environment: Consider the installation space and environmental conditions. The module should be installed in a suitable enclosure, in slot 1 or slot 2 of an RX3i universal backplane or slot 6 of an RX3i 7-slot backplane. Pay attention to the temperature range of the installation environment, which should be within 0 to 60 degrees Celsius.

- Function Requirements: According to the specific requirements of the project, such as the number of I/O points and communication speed requirements, determine whether the functions of IC695PNS001 can meet the needs. If high-speed data transmission and a large number of I/O connections are required, its four Ethernet ports and 32 input and output bits can be well satisfied.

- Budget: Consider your budget constraints. Although IC695PNS001 provides high performance and reliability, you need to make a choice based on the actual situation of the project to ensure cost-effectiveness.

- Installation: When installing the module, make sure to cut off the power supply to avoid electric shock and damage to the module. Follow the installation instructions carefully and install it in the correct slot of the backplane.

- Operation: Do not operate the module in an environment where the temperature and humidity exceed the specified range, so as not to affect its performance and service life. During operation, pay attention to the status of the LED indicators. If an abnormal light is found, check and troubleshoot in time.

- Maintenance: Regularly check the connection of the module to ensure that the connection is firm and there is no looseness. Periodically back up the configuration data to prevent data loss in case of module failure. When performing firmware upgrades, use the correct firmware version and follow the upgrade steps to avoid system failures.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of [IC695PNS001] and other automation spare parts. You can visit our website or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide