Description

1. Product Description

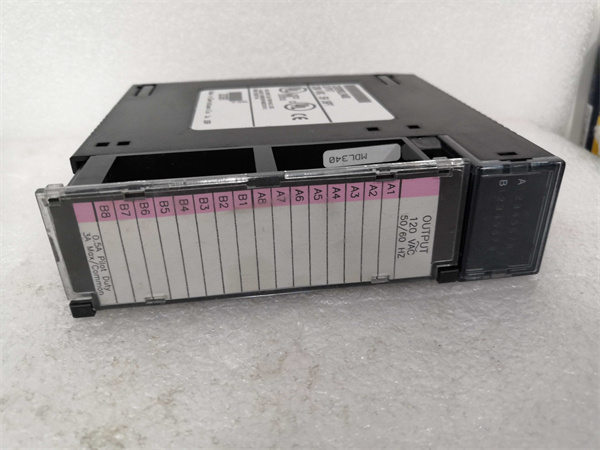

The GE Fanuc IC693MDL340 is a highly – functional module in the realm of Programmable Logic Controller (PLC) systems. The IC693MDL340 is designed to perform precise analog signal acquisition and processing, which is a core function in industrial automation control. Its primary purpose is to collect analog signals from various sensors in industrial settings, such as temperature, pressure, and flow sensors, and convert these signals into digital data that can be processed by the PLC.

One of the key advantages of the IC693MDL340 is its high – level of accuracy and reliability. It can operate stably in harsh industrial environments, ensuring that the collected data is accurate and consistent. This makes it an ideal choice for applications where precision is crucial, such as in chemical manufacturing and power generation. Another advantage is its excellent compatibility with other components in the GE Fanuc 90 – 30 series PLC. This allows for seamless integration into existing or new control systems, reducing the complexity and cost of system setup.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Channels | 16 channels |

| Input Signal Types | Analog input, supporting multiple signal ranges like 0 – 10V, 4 – 20mA, etc. |

| Resolution | 12 – bit |

| Accuracy | ±0.1% of FS (Full Scale) |

| Isolation Method | Optoelectronic isolation between channels |

| Power Supply Voltage | 24V DC ±10% |

| Power Consumption | Typical value of 3W |

| Compatibility | Suitable for GE Fanuc 90 – 30 series PLC |

3. Advantages and Features

- High Reliability: The IC693MDL340 is built with high – quality components and advanced manufacturing processes. It has been rigorously tested and can operate in harsh industrial environments with an average time between failures (MTBF) of over 50,000 hours. For example, in a steel manufacturing plant where there are high temperatures, vibrations, and electromagnetic interference, the IC693MDL340 has been proven to maintain stable operation.

- High – precision Signal Processing: With a 12 – bit resolution and an accuracy of ±0.1% of FS, the IC693MDL340 can accurately capture and process analog signals. This high precision allows for more accurate control of industrial processes. In a pharmaceutical production line, the precise measurement of temperature and pressure by the IC693MDL340 ensures the quality and consistency of the products.

- Easy Integration: The IC693MDL340 follows standard industrial interface specifications, making it easy to connect and configure with other modules in the GE Fanuc 90 – 30 series PLC. This reduces the time and cost of system integration. For instance, when upgrading an existing control system, the IC693MDL340 can be quickly installed and integrated without major modifications.

4. Application Fields and Application Cases

- Application Fields

- Manufacturing: In manufacturing industries, the IC693MDL340 is used for monitoring and controlling analog signals such as temperature, pressure, and flow in production lines. It helps to optimize production processes and improve product quality.

- Energy Sector: In power generation plants, oil refineries, and other energy – related facilities, the IC693MDL340 is used to monitor and regulate various process parameters to ensure safe and efficient operation.

- Water Treatment: In water treatment plants, it is used to monitor water quality parameters such as pH, turbidity, and dissolved oxygen, and to control the dosing of chemicals for water purification.

- Application Case: In an automotive manufacturing plant’s paint shop, the IC693MDL340 is used to monitor and control the temperature and humidity in the paint booth. By accurately collecting analog signals from temperature and humidity sensors and transmitting the data to the PLC control system, real – time monitoring and automatic adjustment of the paint booth environment are achieved. After using the IC693MDL340, the paint quality has been significantly improved, the defect rate has been reduced by 30%, and the production efficiency and equipment stability have also been enhanced.

5. Competitor Comparison

Compared with some similar products on the market, the IC693MDL340 has several advantages. Its accuracy of ±0.1% of FS is higher than that of some competing products, which enables more precise analog signal processing. In terms of reliability, an MTBF of over 50,000 hours is also better than many competitors, effectively reducing production interruptions caused by module failures and lowering maintenance costs. Additionally, its excellent compatibility with the GE Fanuc 90 – 30 series PLC allows for more convenient system integration and function expansion compared to some other products.

6. Selection Advice

- Compatibility: Ensure that the selected IC693MDL340 module is compatible with your existing GE Fanuc 90 – 30 series PLC system, including aspects such as the backplane and power supply. This ensures the normal operation of the system.

- Input Signal Requirements: Based on the types and ranges of analog signals that need to be collected in your actual application, choose an IC693MDL340 module with the appropriate input signal type to ensure accurate signal collection.

- Installation Environment: Consider the environmental conditions at the installation location of the module, such as temperature, humidity, and vibration. Although the IC693MDL340 can adapt to certain harsh environments, ensure that the installation environment is within its allowable operating range to guarantee performance and lifespan.

- Budget: Consider your project budget comprehensively. The IC693MDL340 offers high cost – effectiveness, but still need to balance the overall cost to ensure that the project requirements are met within the budget.

7. Precautions

- Installation: When installing the IC693MDL340 module, make sure to power off the system. Install it correctly on the PLC backplane according to the instructions and tighten the screws to ensure a secure connection.

- Wiring: Carefully connect the input signal cables according to the wiring diagram. Ensure that the wiring is correct to avoid reverse connections or short – circuits, which could damage the module.

- Power Supply: Provide a stable 24V DC power supply, and the power supply voltage fluctuation should be within ±10% to ensure the normal operation of the module.

- Maintenance: Regularly check the operating status of the module, clean the dust on the module surface, and check for loose connections. If any abnormalities are found, repair or replace the module in a timely manner.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IC693MDL340 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide