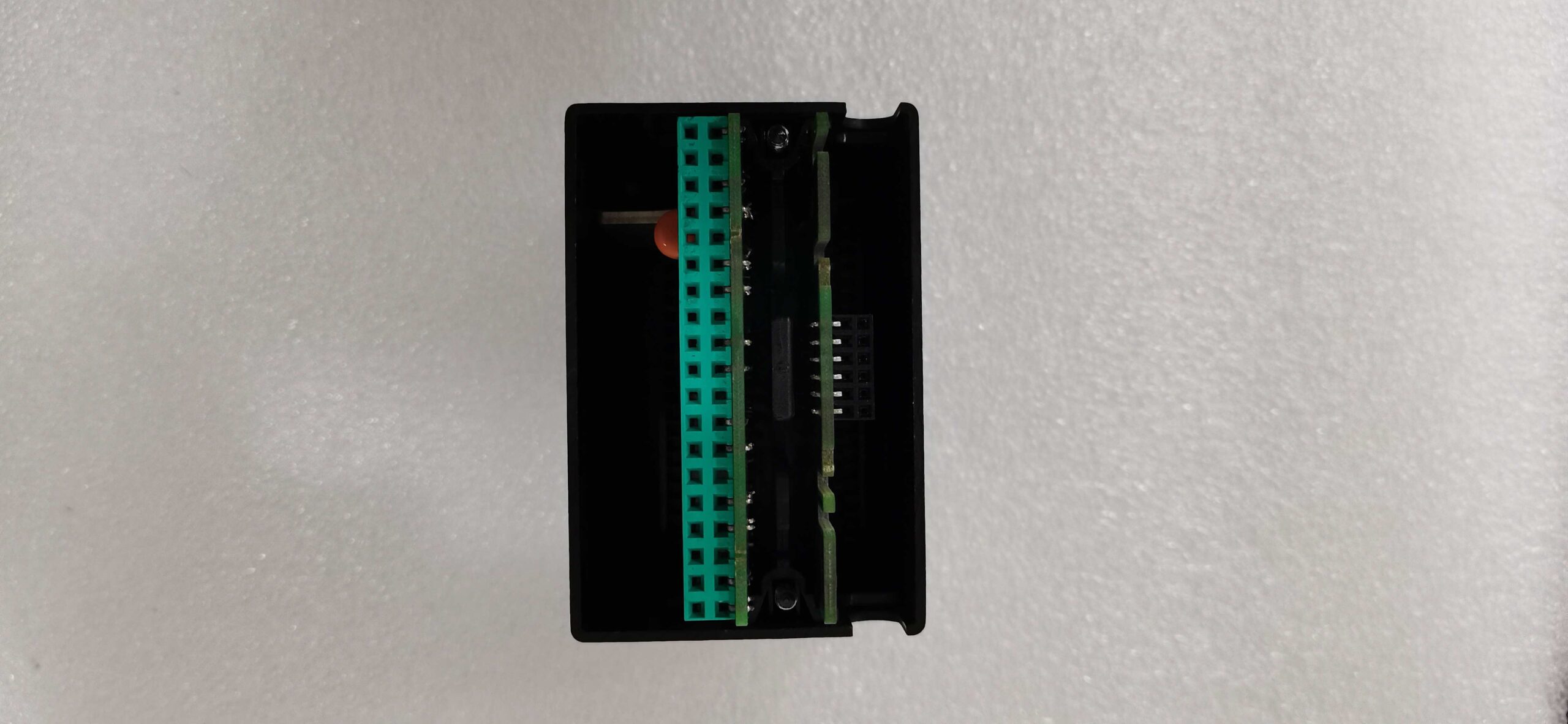

Description

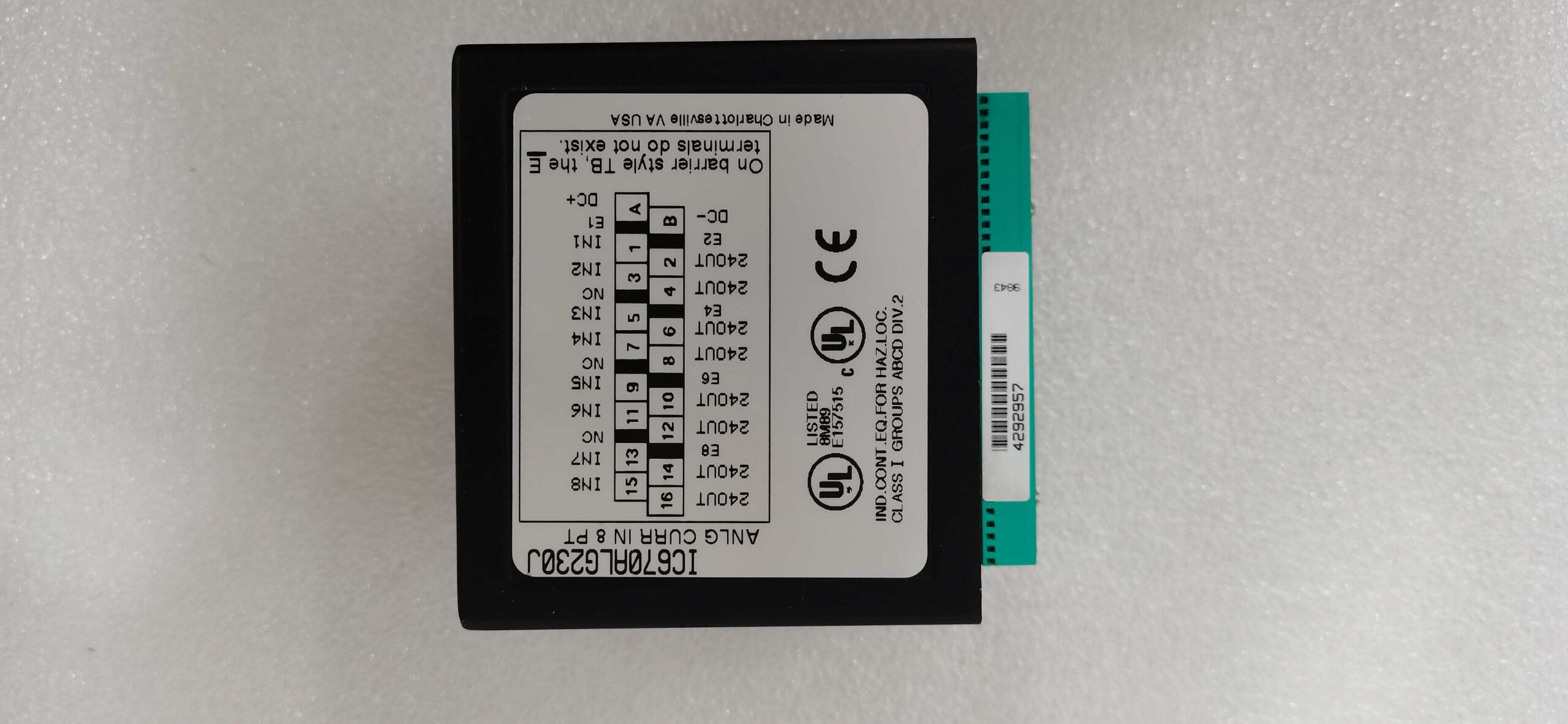

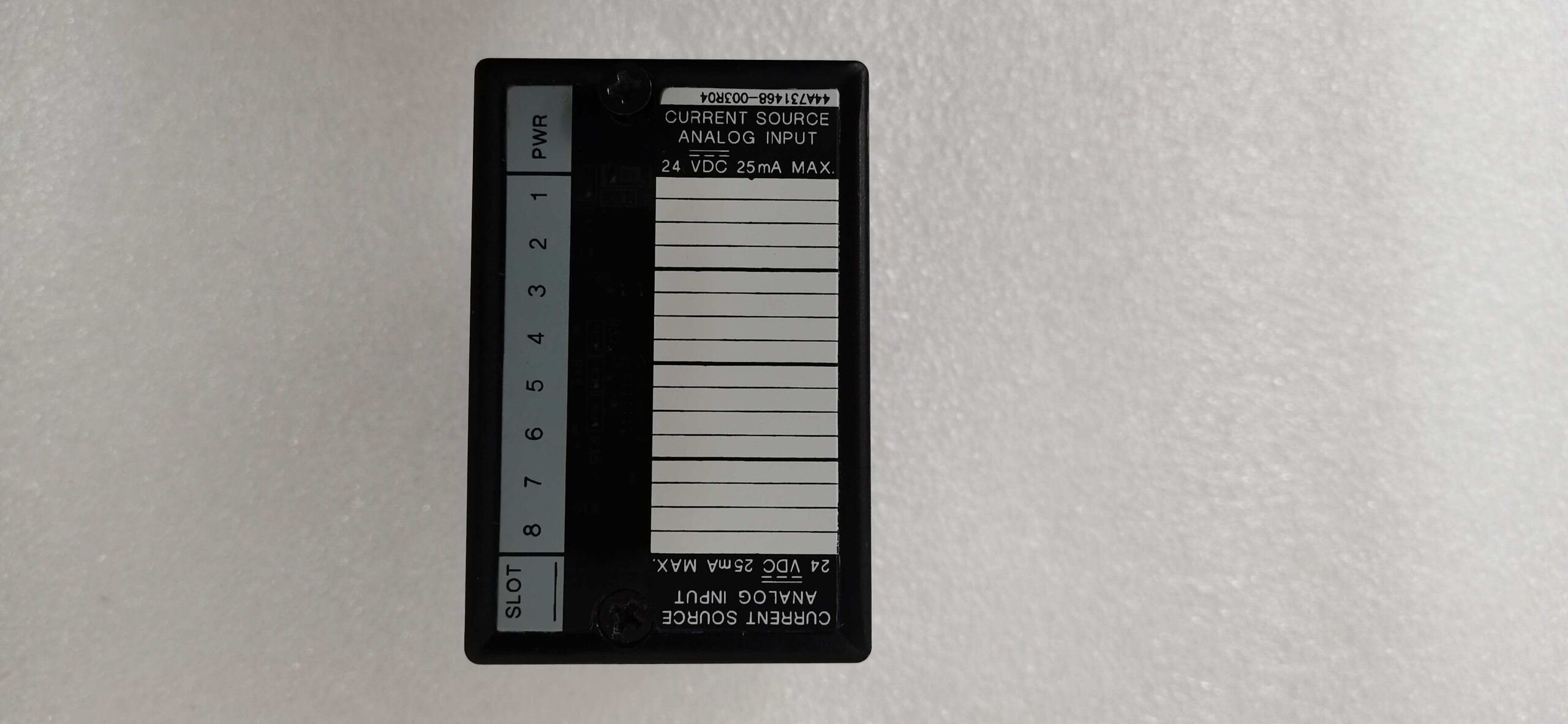

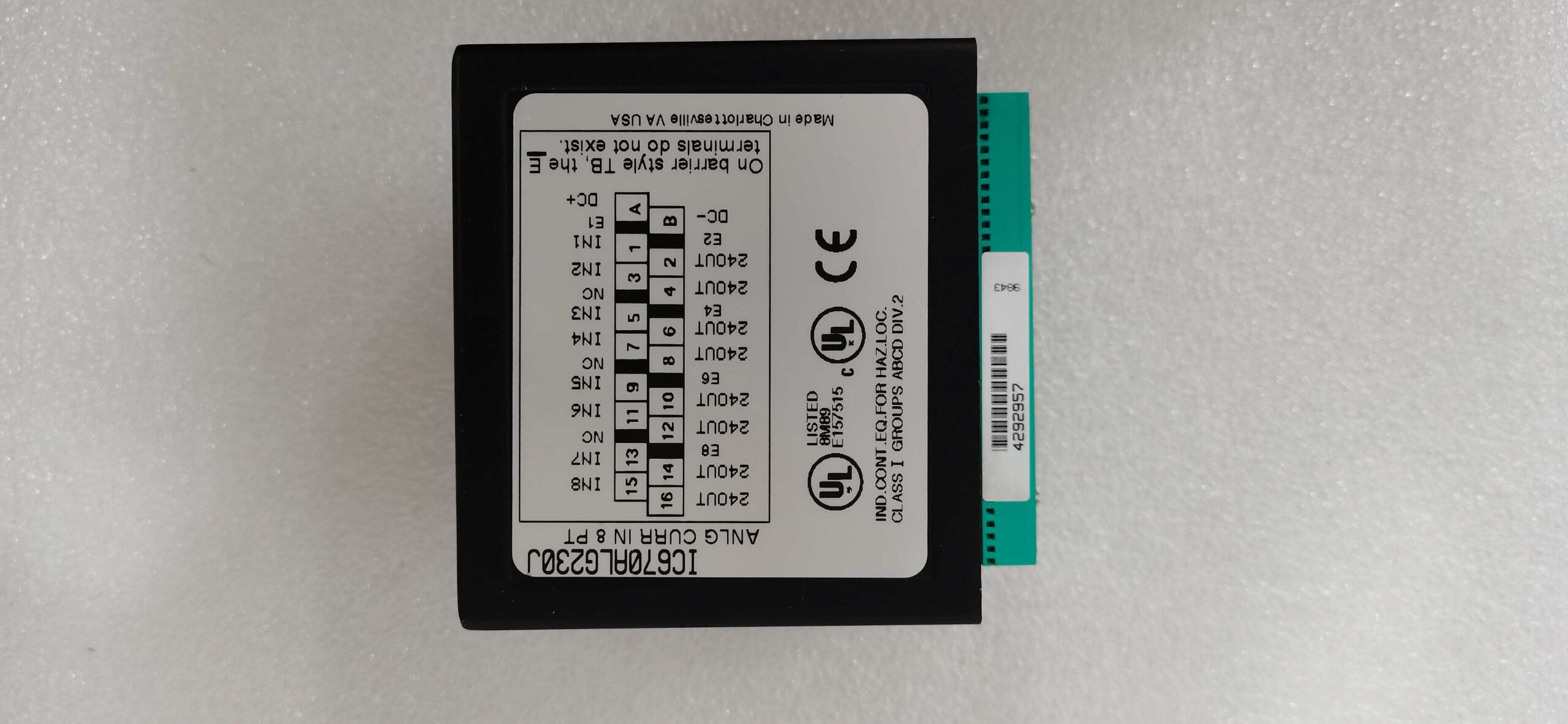

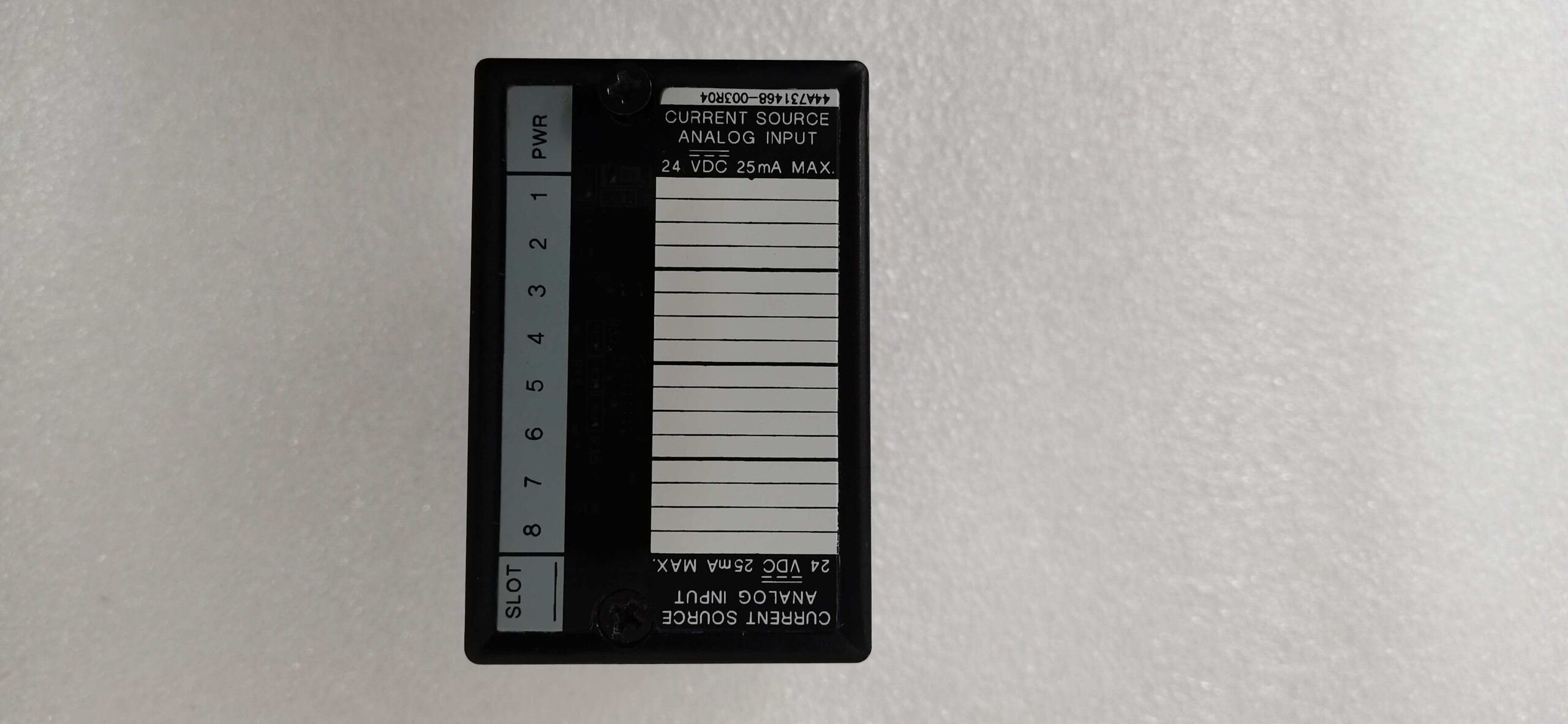

The

IC670ALG230 is a high-performance analog input module designed by

GE Fanuc for its PACSystems RX3i platform. Engineered for industrial automation and process control, the

IC670ALG230 supports 16-channel analog input (4–20mA, ±10V) with 16-bit resolution and advanced signal conditioning. It features galvanic isolation (2.5kVrms), built-in cold-junction compensation for thermocouples, and configurable alarm thresholds. The module integrates with GE’s Proficy software for seamless system integration, enabling real-time monitoring in harsh environments (e.g., temperature ranges of -40°C to 70°C). Ideal for applications requiring precise data acquisition, the

IC670ALG230 ensures reliable operation in power generation, manufacturing, and water treatment systems.

| Parameter |

Specification |

| Input Type |

4–20mA, ±10V, thermocouples (J, K, T, E, R, S, B, N), RTD (Pt100, Pt200, Pt500) |

| Channels |

16 (differential or single-ended) |

| Resolution |

16-bit (±0.015% FSR accuracy) |

| Voltage Range |

±10V (±15V overvoltage protection) |

| Current Range |

4–20mA (30mA max) |

| Isolation |

2.5kVrms (channel-to-chassis/ground) |

| Update Rate |

10ms (per channel) |

| Configuration |

Software-configurable via Proficy Machine Edition (ME) |

| Compatibility |

GE PACSystems RX3i (IC670 series backplane), I/O buses (PCI Express, Ethernet) |

IC670ALG230

- High Precision: 16-bit resolution with ±0.015% accuracy for critical process measurements.

- Versatile Inputs: Supports thermocouples, RTDs, and analog signals without additional modules.

- Rugged Design: Industrial-grade components (coated PCBs, wide temperature range) for 10+ years of service.

- Smart Diagnostics: Real-time channel status (open circuit, overrange), self-test (POST), and fault logging.

- Modular Flexibility: Hot-swap capability and scalable I/O (expandable via RX3i backplane).

Industries: Power generation (gas/steam turbines), oil & gas, water/wastewater, manufacturing.

Applications: Temperature/pressure monitoring, process control loops, machine health diagnostics.

Case Study: A chemical plant in Texas upgraded to the IC670ALG230 for its reactor monitoring system, achieving 99.9% uptime through accurate thermocouple measurements and rapid fault detection (reducing calibration cycles by 40%).

Compared to standard analog input modules:

- Integrated Signal Conditioning: Eliminates need for external transmitters (saves 20–30% in cabling costs).

- Enhanced Isolation: 2.5kVrms protection (industry standard: 1.5kVrms) for noise-sensitive environments.

- Software Native Integration: Predefined tags in GE Proficy ME reduce programming time by 50%.

IC670ALG230

- Compatibility: Verify backplane compatibility (RX3i series; avoid legacy VersaMax systems).

- Environment: Match temperature (-40°C to 70°C) and vibration (5–500Hz, 5g) requirements.

- Scalability: Pair with IC670CPUE050 for distributed control in large-scale systems.

- Installation: Follow GE’s wiring guidelines (separate analog/digital cabling; shielded twisted pairs for thermocouples).

- Calibration: Factory-calibrated (traceable to NIST); recheck every 2 years in high-precision applications.

- Safety: Disconnect power before module replacement; use ESD protection (ESD rating: ±8kV air discharge).

声明: Shanxi XinyeDa International Trade Co., Ltd. is your trusted partner for

IC670ALG230 and GE PACSystems 备件. We offer certified refurbished modules, technical support, and lifecycle management. Visit

www.xydcontrol.com or contact us for GE Fanuc, ABB, and Siemens automation solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide