Description

The

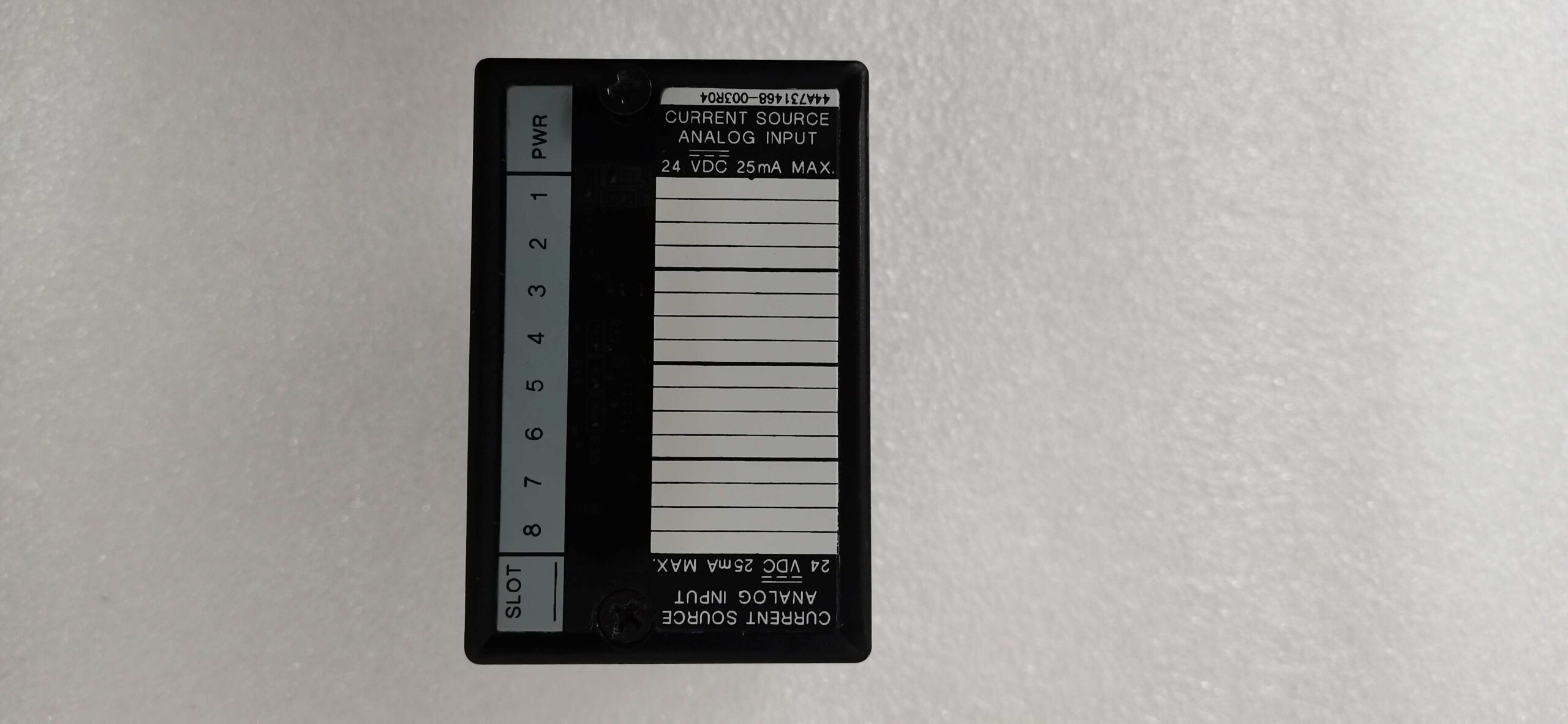

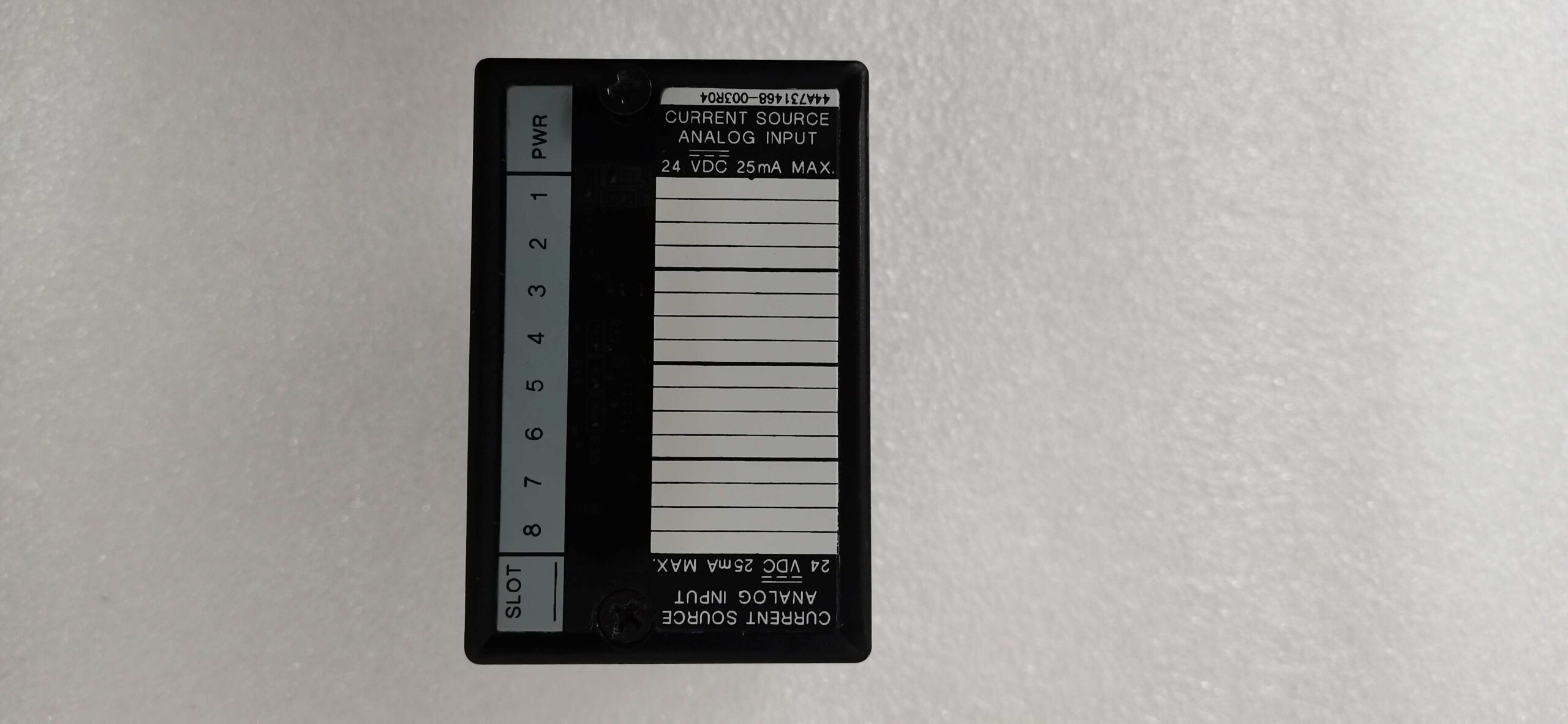

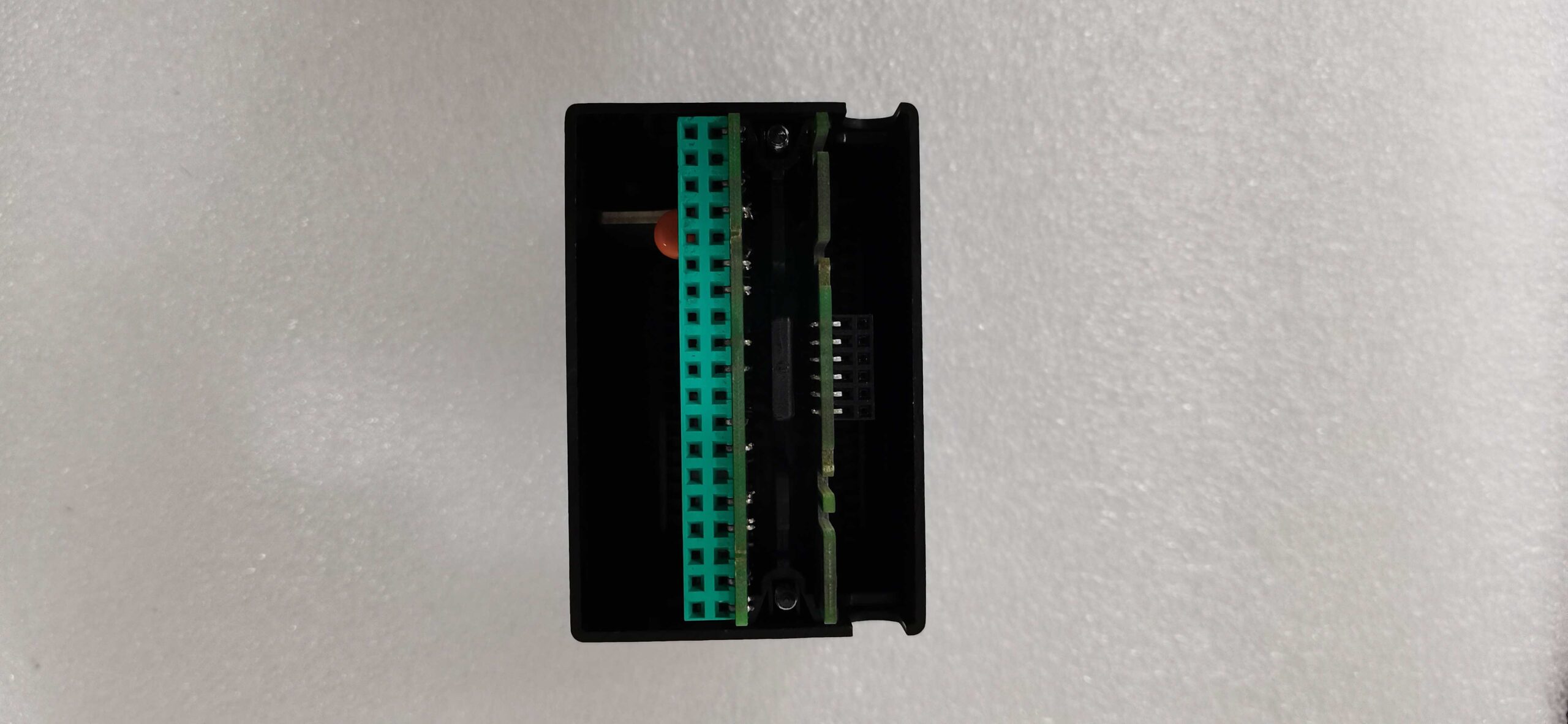

GE Fanuc IC670ALG230 is a high-performance analog output module designed for industrial automation systems, part of the Genius Field Control and RX7i PACSystem families. Its core function is converting digital signals into precise analog voltage/current outputs (e.g., 0–10V voltage or 4–20mA current), making it ideal for controlling valves, actuators, and process equipment. With 16 isolated channels (4 groups of 4), it offers scalable control for complex systems. The module integrates seamlessly with GE’s control platforms, delivering reliability in harsh environments. The

IC670ALG230 supports both voltage and current outputs per channel, with user-configurable scaling and diagnostic features.

| Parameter |

Specification |

| Signal Type |

Voltage (0–10V, ±10V) / Current (4–20mA) |

| Channels |

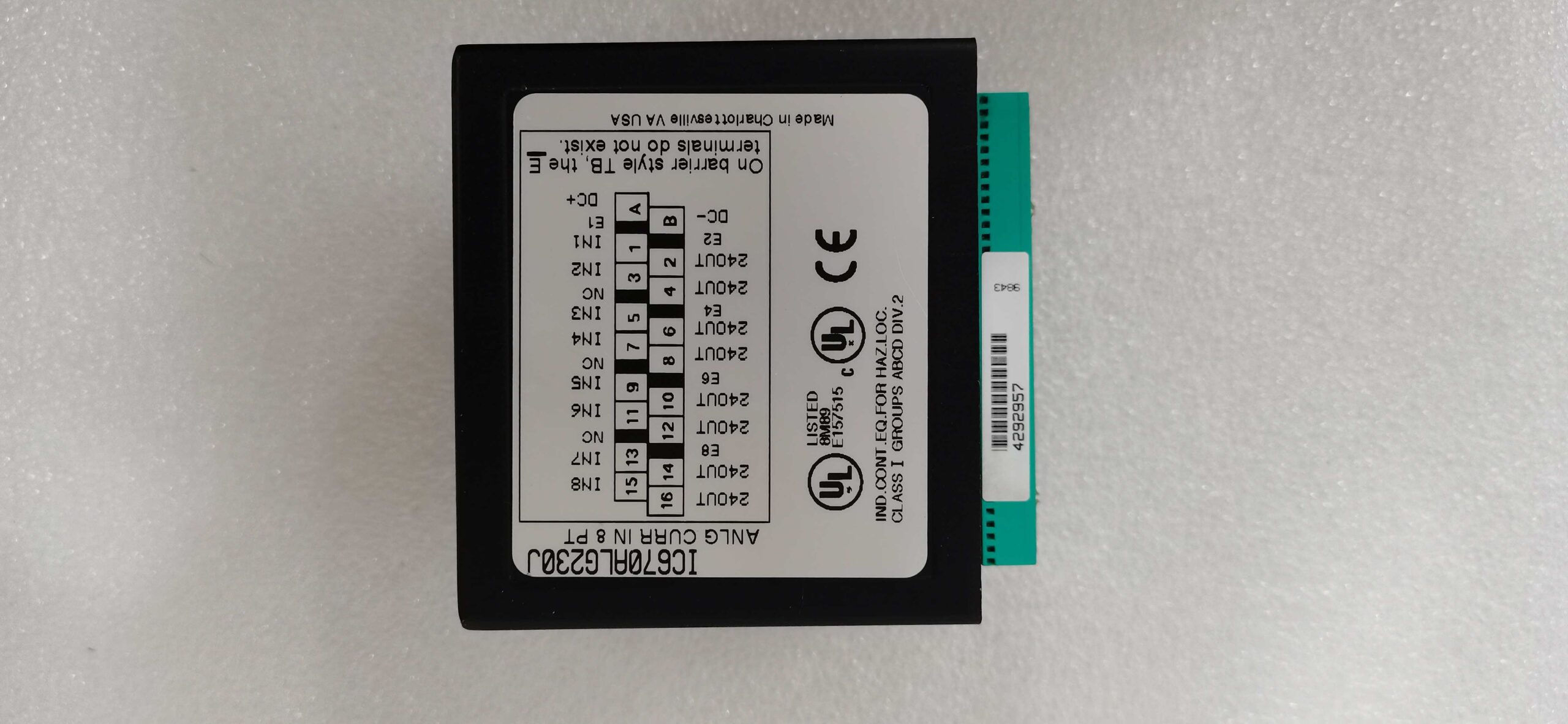

16 (4 isolated groups of 4) |

| Resolution |

14-bit DAC |

| Accuracy |

±0.1% of full scale |

| Power Supply |

External: 18–30V DC; Backplane: 24V DC |

| Current Consumption |

120mA (backplane) |

| Communication |

Genius Field Bus (Rev 2.0+) |

| Operating Temperature |

-20°C to +60°C |

| Dimensions |

3.5 × 13 × 13.6 cm |

IC670ALG230

- High Channel Density: 16 channels (vs. 8–12 in many alternatives) reduce cabinet space and wiring costs.

- Isolated Group Design: Four isolated groups (4 channels each) prevent cross-channel interference.

- Flexible Configuration: Per-channel voltage/current selection with 5 scaling options (including custom).

- Advanced Diagnostics: Real-time fault detection (over/under range, short circuit) with LED indicators for quick troubleshooting.

- Wide Temperature Range: Operates in -20°C to +60°C environments, suitable for extreme industrial settings.

Industries: Oil & gas, water treatment, manufacturing, power generation.

Scenarios: Multi-zone temperature control, pump speed regulation, process automation.

Case Study: A water treatment plant used the IC670ALG230 to control 16 chemical dosing pumps. Its 16-channel design reduced I/O module count by 50%, while 14-bit precision ensured ±0.5% dosing accuracy, cutting chemical waste by 20%.

Compared to similar modules:

- Higher Channel Density: 16 channels (versus 8–12 in most 竞品).

- Dual Signal Support: Voltage/current per channel (many alternatives require fixed signal types).

- Integrated Isolation: Four isolated groups (vs. single isolation in basic models).

IC670ALG230

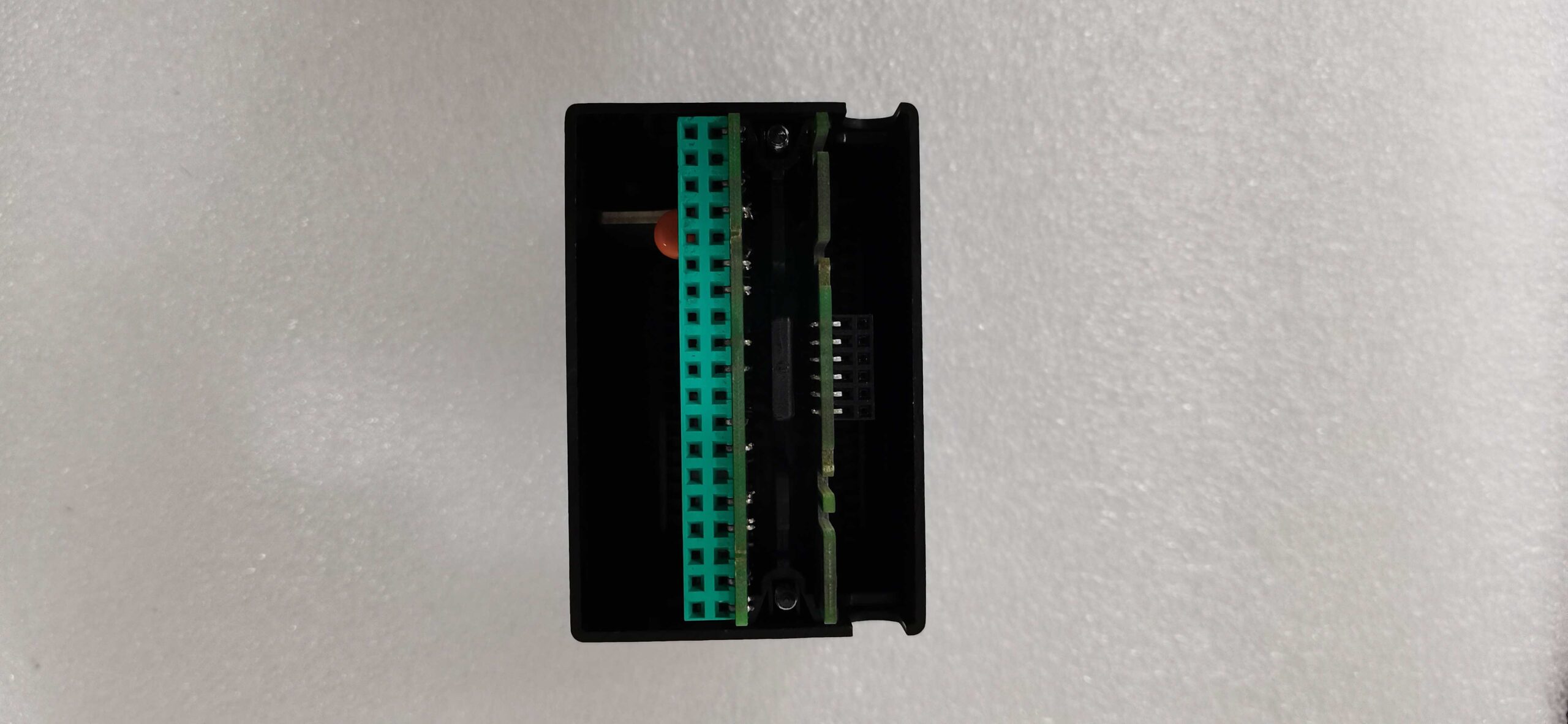

- Compatibility: Ensure Genius Field Bus Rev 2.0+ and GE I/O chassis (e.g., RX3i, RX7i).

- Channel Needs: Choose 16 channels for high-density applications; opt for lower-channel modules (e.g., IC670ALG310) for simpler systems.

- Environment: Verify temperature (-20°C to +60°C) and vibration resistance match site conditions.

-

Power Management: Use a filtered external power supply (18–30V DC) to avoid signal noise.

-

Wiring Practices: Use twisted-pair shielded cables for analog lines; follow polarity guidelines for terminals.

-

Calibration: Factory-calibrated; recheck annually or after system upgrades.

-

Hot Swap: Follow GE’s safety protocols for module replacement in live systems.

Shanxi XinyeDa International Trade Co., Ltd. is your trusted partner for

GE Fanuc IC670ALG230 and other automation spare parts. We provide sales, technical support, and customized solutions. Visit

www.xydcontrol.com or contact us for expert assistance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide