Description

The

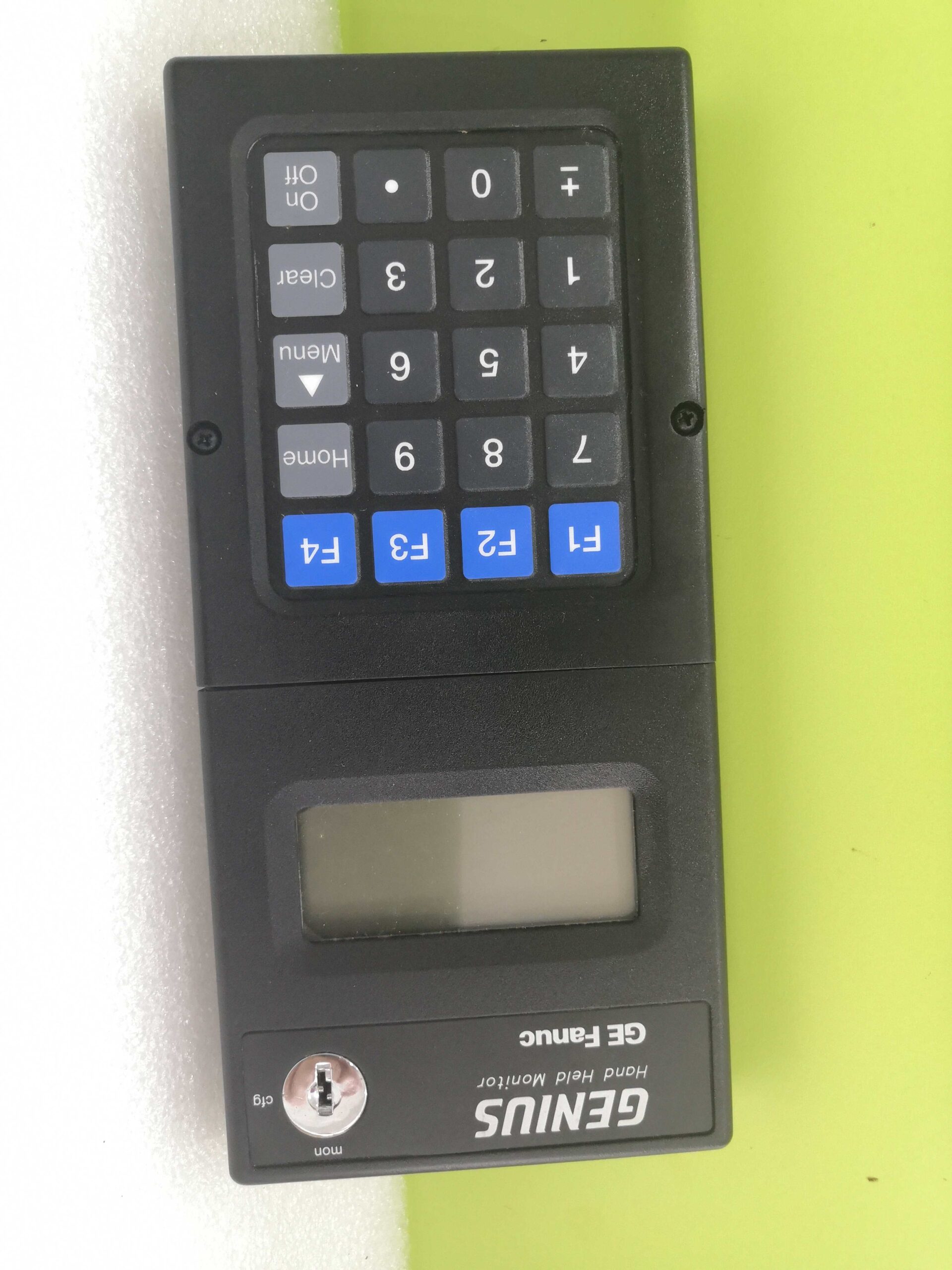

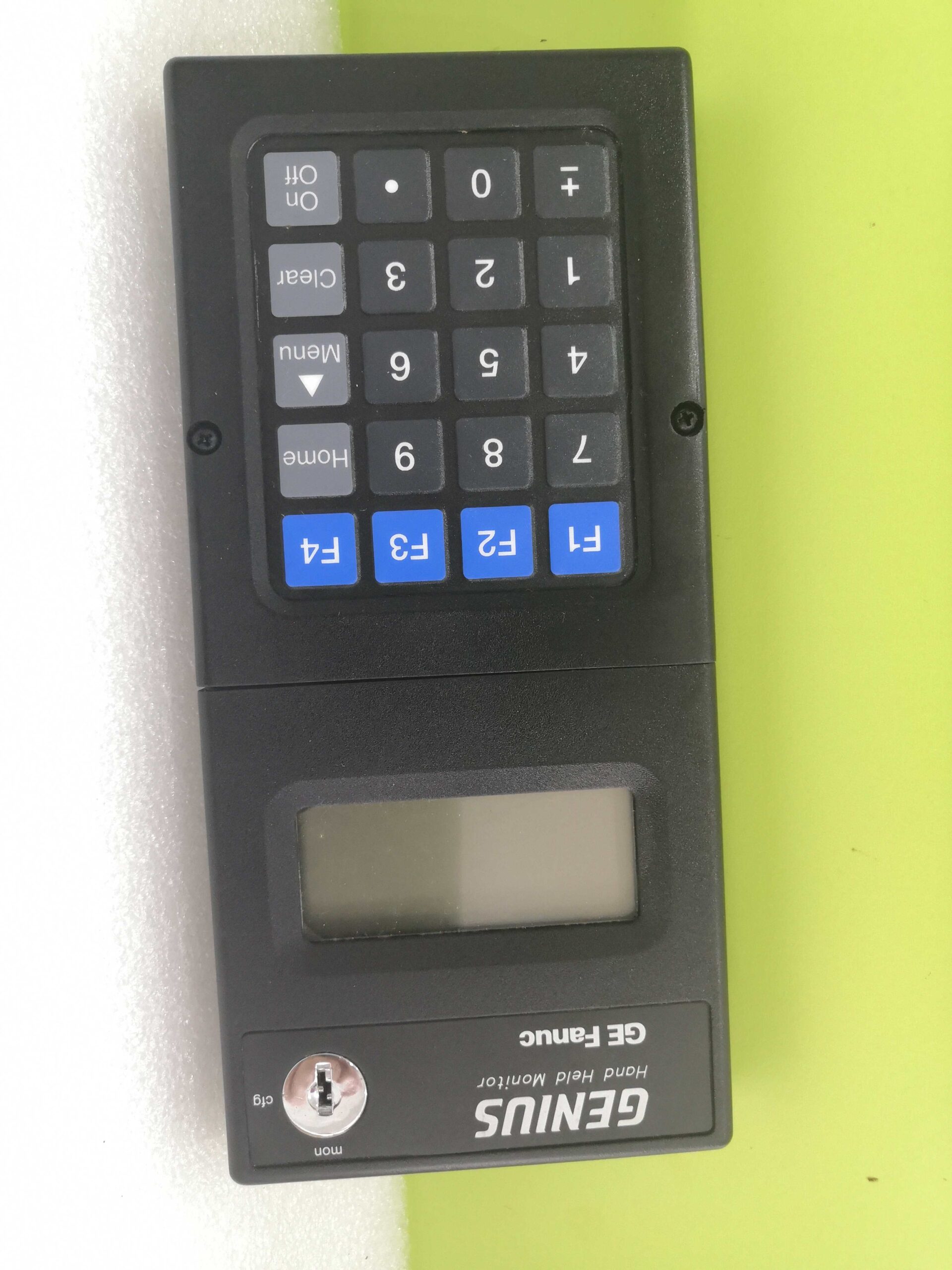

IC660HHM501N is a remarkable human – machine interface (HMI) module from GE Fanuc, a renowned brand in the industrial automation field. This module is designed to bridge the gap between operators and industrial control systems, facilitating seamless interaction and efficient process management.

The core function of the IC660HHM501N is to offer a visual and interactive platform for operators to monitor and control industrial processes. It can collect real – time data from Programmable Logic Controllers (PLCs) and other field devices, and present it in an intuitive graphical format. Operators can use the touch – sensitive screen of the IC660HHM501N to access various control functions, adjust parameters, and receive alarms and notifications.

In industrial settings, the IC660HHM501N finds wide applications. In manufacturing plants, it enables operators to oversee the production line, manage machine operations, and ensure product quality. In energy facilities, it helps in monitoring power generation, distribution, and consumption, allowing for optimal energy management.

One of the key advantages of the IC660HHM501N is its high – quality display. It features a sharp and clear screen that can present detailed process information, making it easy for operators to read and interpret. Another advantage is its user – friendly interface design. The intuitive layout and navigation of the IC660HHM501N reduce the learning curve for operators, enabling them to quickly adapt to the system. Additionally, the module is highly reliable, built to withstand the rigors of industrial environments, including temperature variations, dust, and vibrations.

| Parameter |

Details |

| Power Supply |

24V DC (±10%) |

| Display Size |

10.4 inches |

| Resolution |

800 x 600 pixels |

| Touchscreen Technology |

Resistive touchscreen |

| Communication Interfaces |

Ethernet (10/100 Mbps), RS – 232, RS – 485 |

| Memory |

128 MB Flash, 64 MB SDRAM |

| Operating Temperature |

0°C – 50°C |

| Storage Temperature |

– 20°C – 60°C |

| Compatibility |

Compatible with GE Fanuc’s 90 – 30, 90 – 70 series PLCs |

- High – Quality Display: The 10.4 – inch display with 800 x 600 pixels resolution provides a clear and vivid presentation of process data. In a food processing plant, operators can easily monitor the temperature, pressure, and flow rate of various production stages, ensuring consistent product quality.

- User – Friendly Interface: The resistive touchscreen and well – designed graphical user interface (GUI) make it simple for operators to interact with the system. In a packaging plant, new operators can quickly learn to use the IC660HHM501N to adjust packaging parameters, reducing the time required for training.

- Reliability: With a mean time between failures (MTBF) of over 50,000 hours, the IC660HHM501N offers long – term stable operation. In a chemical plant, it has been operating continuously for several years without any major breakdowns, minimizing production disruptions.

- Multiple Communication Interfaces: The availability of Ethernet, RS – 232, and RS – 485 interfaces allows for easy integration with different types of industrial devices and systems. In a large – scale industrial complex, the IC660HHM501N can communicate with multiple PLCs and other equipment, enabling centralized control and monitoring.

- Application Areas: The IC660HHM501N is used in manufacturing (automotive, electronics, food processing), energy (power generation, oil and gas), water treatment, and building automation industries.

- Application Case: In an automotive assembly plant, the IC660HHM501N was installed at each workstation. Operators could use it to monitor the status of robots, control the movement of conveyor belts, and receive real – time feedback on production quality. As a result, the production efficiency increased by 18%, and the defect rate decreased by 12%.

Compared to similar products in the market, the IC660HHM501N offers a better combination of display quality, user – friendliness, and reliability. Some competing HMIs may have lower – resolution displays or less intuitive interfaces, which can lead to operator errors and reduced productivity. The wide range of communication interfaces in the IC660HHM501N also gives it an edge, as it provides more flexibility in system integration compared to products with limited connectivity options.

- Compatibility: Ensure that the IC660HHM501N is compatible with your existing PLC system and other industrial devices. Check the communication protocols and electrical requirements.

- Display and Interface Requirements: Consider the size, resolution, and touchscreen technology of the display based on your application needs. If you need to display detailed graphics or operate in a high – precision environment, a high – resolution display like the IC660HHM501N may be necessary.

- Installation Environment: Evaluate the temperature, humidity, and other environmental factors of the installation site. The IC660HHM501N has a specified operating temperature range, and extreme conditions may require additional protective measures.

- Budget: Compare the cost of the IC660HHM501N with your budget. While it offers high – end features, consider the long – term benefits in terms of improved efficiency, reduced downtime, and better process control.

- Installation: Follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Mount the module securely to avoid vibrations and damage.

- Maintenance: Regularly clean the touchscreen and display to maintain clarity. Check the communication cables and power connections for any signs of wear or damage.

- Safety: When working with the IC660HHM501N, follow all safety procedures. Disconnect the power supply before performing any maintenance or repair work to avoid electric shock.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IC660HHM501N and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide