Description

1. Product Overview

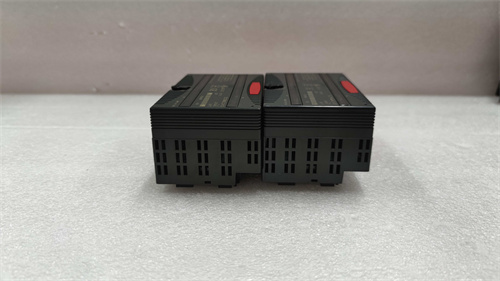

The IC200MDL650 is a digital input module within the GE Intelligent Platforms IC200 series of Programmable Logic Controllers (PLCs). In industrial automation, digital input modules are used to interface the PLC with the real – world digital signals, allowing the PLC to monitor the status of various devices and events.

2. Functionality

- Signal Input Reception

- The primary function of the IC200MDL650 is to receive digital input signals from external devices. These devices can include push – buttons, limit switches, proximity sensors, and other devices that produce on – off (binary) signals. For example, a limit switch on a conveyor belt can send a digital signal to the module when the belt reaches a certain position.

- Signal Conditioning and Isolation

- The module performs signal conditioning on the incoming digital signals. This may involve filtering out electrical noise to ensure that the signals received by the PLC are clean and reliable. It also provides electrical isolation between the external devices and the PLC system. This isolation protects the PLC from electrical interference and potential damage caused by voltage spikes or short – circuits in the external devices.

- Data Transfer to PLC

- Once the digital signals are received and conditioned, the module transfers the data to the PLC’s central processing unit (CPU). The CPU can then use this data to execute control logic and make decisions, such as starting or stopping a motor, opening or closing a valve, etc.

3. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC ±[X]% (where [X] is typically around 10% to account for normal voltage fluctuations in industrial power supplies). A stable power supply is essential for the proper operation of the module. |

| Number of Input Channels | [X] channels (e.g., 8, 16, 32). Each channel can be connected to a different digital input device, allowing the module to monitor multiple signals simultaneously. |

| Input Voltage Range | It is designed to accept a specific input voltage range to detect the digital signals. For example, it may be able to detect a high – level signal (logic 1) when the input voltage is within the range of 15 – 30V DC and a low – level signal (logic 0) when the voltage is below a certain threshold (e.g., 5V DC). |

| Response Time | The response time of the input channels is an important parameter. It refers to the time it takes for the module to detect a change in the input signal and transfer the new data to the PLC. A fast response time is beneficial for applications that require quick detection of events, such as high – speed machinery control. |

| Isolation Voltage | The module provides electrical isolation between the input channels and the internal circuitry of the PLC. The isolation voltage is typically specified, for example, [X] VAC or VDC. This isolation protects the PLC from electrical interference and damage. |

| Operating Temperature | – 20°C to 60°C. This wide temperature range ensures that the module can operate reliably in different industrial environments, from cold storage areas to hot manufacturing plants. |

| Dimensions | [Length] x [Width] x [Height] (mm). The compact design is suitable for installation in control cabinets or other industrial enclosures. |

| Weight | [X] kg |

4. Advantages

- Reliability

- Built with high – quality components, the IC200MDL650 has a long mean time between failures (MTBF). In continuous – running industrial processes, this reliability ensures minimal downtime and reduced maintenance costs. For example, in a 24/7 manufacturing line, the module can operate without interruption, providing accurate input data to the PLC.

- Isolation and Protection

- The electrical isolation provided by the module protects the PLC from external electrical interference and damage. This helps to ensure the long – term stability and performance of the entire automation system.

- Flexibility

- With multiple input channels, the module offers flexibility in monitoring different types of digital input devices. It can be used in a variety of industrial applications, from simple control tasks to complex automation systems.

5. Application Fields

- Manufacturing

- In automotive manufacturing, the module can be used to monitor the position of robotic arms, the status of conveyor belts, and the operation of safety switches. For example, it can detect when a robotic arm has reached a specific position and send the signal to the PLC to initiate the next step in the assembly process.

- In electronics manufacturing, it can be used to monitor the operation of circuit board testing equipment, the status of pick – and – place robots, and the opening and closing of access doors.

- Energy Sector

- In power plants, it can be used to monitor the status of circuit breakers, the position of valves, and the operation of safety sensors. For example, it can detect when a circuit breaker has tripped and send the signal to the PLC for further action.

- In renewable energy systems, such as wind farms, it can be used to monitor the status of turbine blades, the operation of yaw systems, and the opening and closing of maintenance doors.

- Water and Wastewater Treatment

- In water treatment plants, it can be used to monitor the status of pumps, the position of valves, and the operation of level sensors. For example, it can detect when a water tank is full and send the signal to the PLC to stop the pump.

6. Selection Considerations

- Compatibility

- Ensure that the IC200MDL650 is compatible with your existing IC200 series PLC system, including the power supply, communication protocol, and other modules in the rack.

- Input Requirements

- Evaluate your specific requirements for the number of input channels, input voltage range, and response time. Consider the types of digital input devices you will be connecting to the module and their electrical characteristics.

- Budget

- Compare the cost of the IC200MDL650 with other similar digital input modules in the market. Consider the long – term benefits of reliability, isolation, and flexibility when making a decision.

7. Precautions

- Installation

- Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, input devices, and the PLC system are secure.

- Operation

- Do not exceed the specified operating parameters, such as power supply voltage, input voltage range, and temperature limits. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance

- Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer the IC200MDL650 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide