Description

1. Product Description

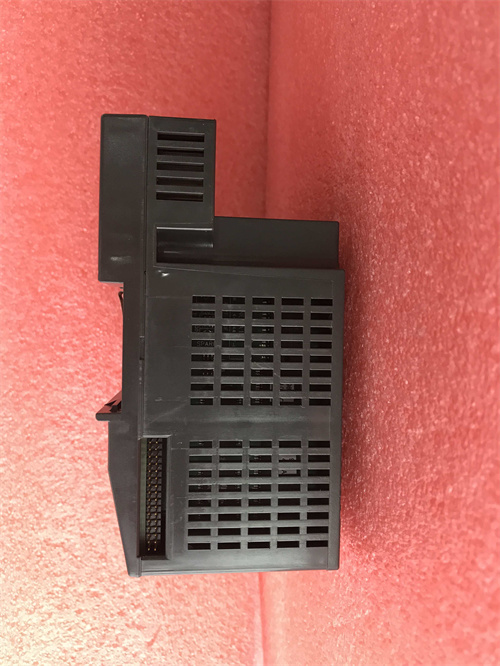

The IC200CPUE05 is a central processing unit (CPU) module from GE Fanuc, a renowned brand in the field of industrial automation. This module serves as the core component of a programmable logic controller (PLC) system, playing a pivotal role in executing control programs and managing various operations within industrial applications.

The IC200CPUE05 is designed to handle complex control algorithms with ease. It processes input signals from sensors and other field devices, makes logical decisions based on the programmed instructions, and sends out control signals to actuators. With its advanced processing capabilities, the IC200CPUE05 can ensure the efficient and stable operation of industrial processes.

One of the key advantages of the IC200CPUE05 is its versatility. It can be used in a wide range of industrial settings, from manufacturing plants to power generation facilities. The module is equipped with multiple communication interfaces, allowing it to communicate with other devices and systems, which enhances the overall integration and coordination of the industrial automation setup.

Moreover, the IC200CPUE05 offers reliable performance. It is built with high-quality components and has undergone rigorous testing to ensure its durability and stability in harsh industrial environments. This makes it a trusted choice for industries where system downtime is not acceptable.

In summary, the IC200CPUE05 is a powerful and reliable CPU module that provides essential control and processing functions for industrial automation systems, enabling users to achieve higher productivity and better control over their operations.

2. Product Parameters

| Parameter | Details |

|---|---|

| Operating Voltage | 24V DC (±10%) |

| Power Consumption | Approximately 5W |

| Processor Type | High-performance microprocessor |

| Memory Capacity | Program memory: 512KB, Data memory: 256KB |

| Communication Interfaces | RS-232, RS-485, Ethernet |

| Input/Output Expansion | Supports connection with various IC200 series I/O modules |

| Compatibility | Compatible with GE Fanuc’s specific PLC systems and software |

| Operating Temperature Range | 0°C to 60°C |

| Storage Temperature Range | -20°C to 85°C |

3. Advantages and Features

- High Processing Speed: The IC200CPUE05 is equipped with a high-performance microprocessor that can execute instructions at a rapid pace. It has a processing speed that allows for quick response to input changes, enabling real-time control in industrial processes. For example, in a high-speed manufacturing line, it can process sensor inputs and issue control commands within milliseconds, ensuring smooth operation and reducing production errors.

- Abundant Memory: With 512KB of program memory and 256KB of data memory, the module can store complex control programs and a large amount of data. This enables users to implement advanced control strategies and store historical data for analysis, which helps in optimizing the production process.

- Versatile Communication: The presence of RS-232, RS-485, and Ethernet interfaces provides flexibility in communication. It can connect to different devices such as HMIs, other PLCs, and SCADA systems, facilitating seamless data exchange and system integration. In a large industrial plant, it can communicate with multiple subsystems, enabling centralized control and monitoring.

- Reliability: Built with high-quality components and designed to withstand harsh industrial environments, the IC200CPUE05 has a long mean time between failures (MTBF). It has been proven to operate stably in environments with high temperatures, humidity, and electromagnetic interference, reducing the risk of system breakdowns and minimizing downtime.

4. Application Areas and Application Cases

- Application Areas: The IC200CPUE05 is suitable for various industries including manufacturing (automotive, electronics, etc.), energy (power generation, oil and gas), water treatment, and building automation.

- Application Case: In a large-scale automotive manufacturing plant, the IC200CPUE05 was used to control the assembly line operations. It was connected to numerous sensors that monitored the position and movement of car parts, as well as actuators that controlled robotic arms and conveyor belts. The high processing speed of the IC200CPUE05 allowed for real-time control and adjustment of the assembly process. As a result, the production efficiency increased by 20%, and the error rate decreased significantly. The module’s reliable performance also ensured that the assembly line operated continuously without major interruptions, saving a significant amount of production time and costs.

5. Competition Comparison

Compared to other similar CPU modules in the market, the IC200CPUE05 stands out with its combination of high processing speed, abundant memory, and versatile communication interfaces. While some competing products may offer only limited communication options or have a smaller memory capacity, the IC200CPUE05 provides a more comprehensive solution. Its reliability in harsh environments is also superior to many alternatives, which makes it a more cost-effective choice in the long run as it reduces the need for frequent replacements and maintenance due to failures.

6. Selection Suggestions

- Compatibility: Ensure that the IC200CPUE05 is compatible with your existing PLC system and other devices in the setup. Check the communication protocols, software compatibility, and physical connections to avoid any integration issues.

- Installation Environment: Consider the operating temperature, humidity, and electromagnetic interference levels of the installation site. The IC200CPUE05 is designed to operate in a certain temperature range, so make sure the environment does not exceed these limits. If the environment is prone to high levels of electromagnetic interference, appropriate shielding measures may be required.

- Function Requirements: Evaluate your specific control requirements. If you need to execute complex control algorithms or store a large amount of data, the IC200CPUE05’s processing speed and memory capacity should be sufficient for your needs. Also, consider the number of communication interfaces required for connecting to other devices.

- Budget: While the IC200CPUE05 offers excellent performance and features, it is important to consider your budget. Compare the cost of the module with the benefits it provides in terms of productivity improvement, reliability, and reduced downtime. Consider the long-term cost savings associated with its reliable operation when making a decision.

7. Precautions

- Installation: When installing the IC200CPUE05, follow the manufacturer’s instructions carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the system. Connect the power supply correctly and make sure the voltage is within the specified range.

- Maintenance: Regularly check the module for any signs of damage or overheating. Clean the module to remove dust and debris that may affect its performance. Update the firmware as recommended by the manufacturer to ensure the latest features and security patches are applied.

- Safety: When working with the IC200CPUE05, follow all safety procedures. Disconnect the power supply before performing any maintenance or repair work. Use appropriate tools and equipment to avoid damage to the module. If there are any abnormal symptoms such as unusual noises or smells, immediately stop the operation and investigate the cause.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for IC200CPUE05 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components