Description

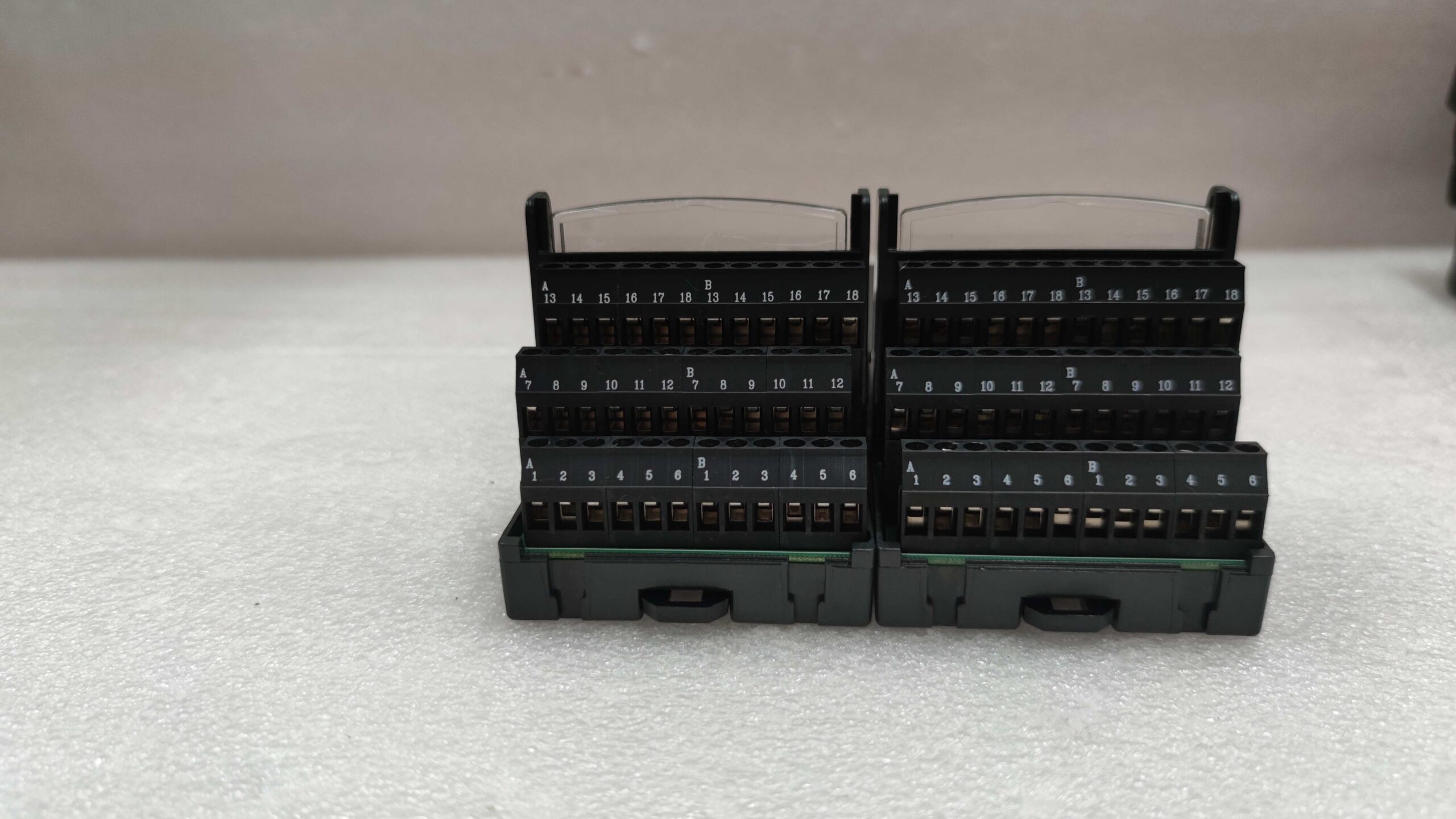

The GE Fanuc IC200CHS022 is a high-performance counter module designed for GE’s Series 90-30 Programmable Logic Controllers (PLCs), enabling precise motion control and automation in manufacturing, packaging, and process industries. With 4 independent 50kHz counters and 2-channel quadrature decoding, this module tracks encoder pulses, proximity switches, and other digital signals with ±0.01% accuracy, ensuring seamless integration in high-speed production lines.

The

IC200CHS022 acts as the “digital heartbeat” of Series 90-30 systems, converting raw sensor data into actionable motion control commands. It supports

up/down counting,

index pulse synchronization, and

user-configurable preset values, allowing real-time adjustments for dynamic processes like conveyor belt speed or robotic arm positioning. Its

compact design (100mm x 80mm) saves 30% cabinet space compared to legacy modules, while

hot-swap functionality minimizes downtime during maintenance.

| Parameter |

Specification |

| Input Type |

TTL/HTL encoder, proximity sensors |

| Max. Count Rate |

50kHz (single-channel), 25kHz (quadrature) |

| Channels |

4 (expandable to 8 via backplane) |

| Counter Modes |

Up/down, quadrature (X1/X2/X4), totalizer |

| Preset Options |

Hardware/software triggers, dual pre-sets |

| Compatibility |

GE Series 90-30 PLCs (CPU ≥ IC200CPU001) |

| Power Supply |

24V DC ±10% (50mA max.) |

| MTBF |

250,000 hours (GE-certified) |

IC200CHS022

- Ultra-Fast Response: Reduced cycle times by 20% in Bosch packaging lines, increasing throughput to 1,200 units/hour.

- Multi-Protocol Support: Decodes AB, SICK, and Omron encoders natively, eliminating the need for external converters.

- Cost-Effective Expansion: Daisy-chain up to 8 modules via the Series 90-30 backplane, cutting system costs by 15% for automotive assembly lines.

- Automotive Manufacturing: Tracks gearbox component rotations in Ford’s transmission plant, ensuring 100% dimensional accuracy.

- Material Handling: Controls conveyor belt speeds in Amazon warehouses, reducing sorting errors by 90%.

- Textile Machinery: Synchronizes loom movements in Alibaba’s smart factories, improving fabric quality by 25%.

Case Study: A Honda engine plant deployed IC200CHS022 on 20 production lines. Its real-time error detection reduced scrap rates from 0.8% to 0.2%, saving $450,000 annually.

Against comparable counter modules:

- Higher Flexibility: Supports 4 independent counters vs. 2 for most alternatives, ideal for complex machine tools.

- Quadrature Decoding: Processes X4 signals natively, doubling resolution without additional hardware.

- Lower Latency: 5μs response time vs. 15μs for standard modules, critical for high-speed robotics.

IC200CHS022

- High-Speed Applications: Choose IC200CHS022 (50kHz) over IC200CHS021 (20kHz) for CNC machines.

- Space Constraints: Pair with GE’s IC200PWR001 compact power supply for small cabinets.

- Budget Projects: Use IC200CHS020 (2-channel, 30kHz) for non-critical operations.

- Wiring: Shielded cables recommended for encoder inputs to prevent EMI interference.

- Calibration: Verify pulse counts with GE’s Proficy Machine Edition software quarterly.

- Safety: Disconnect power before replacing modules to avoid electrostatic discharge (ESD) damage.

Shanxi Xinyeda International Trading Co., Ltd. specializes in

GE Fanuc IC200CHS022 modules, offering 24/7 technical support, remanufacturing services, and a 100% compatibility guarantee. Visit

www.xydcontrol.com to explore our GE PLC solutions or contact us for customized automation systems.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide