Description

1. Product Overview

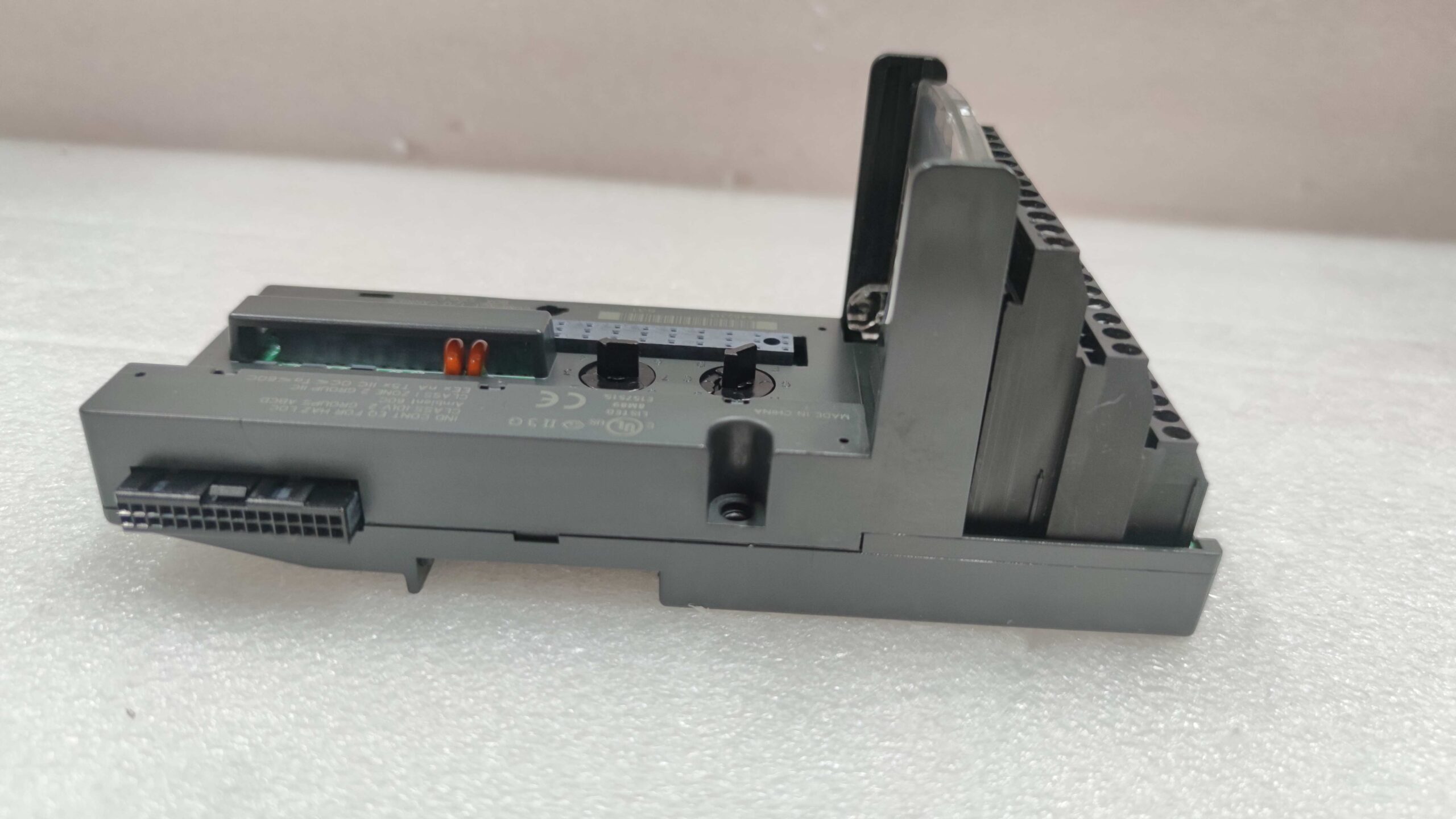

The IC200CHS022 is a component within the IC200 series of programmable logic controllers (PLCs) from GE Intelligent Platforms. PLCs are essential in industrial automation for controlling and monitoring various processes. This particular module likely serves a crucial role in facilitating communication and system integration within the overall PLC setup.

2. Functionality

- Communication Hub: It acts as a communication hub within the IC200 PLC system. It enables the exchange of data between different modules in the PLC rack, such as input – output (I/O) modules, processor modules, and other specialized function modules. For example, it can transfer the data collected by I/O modules from sensors in the field to the central processor for analysis and decision – making.

- Protocol Support: The IC200CHS022 supports specific communication protocols. These protocols are used to ensure reliable and efficient data transfer within the industrial network. Common protocols it might support include Modbus, which is widely used in industrial automation for communication between different devices, or other proprietary protocols designed for seamless integration within the IC200 series.

- System Expansion: It plays a role in system expansion. As the industrial process grows or changes, additional I/O modules or other components may need to be added to the PLC system. The IC200CHS022 allows for the easy connection and integration of these new modules, ensuring that the system can scale up to meet the increasing requirements.

3. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC ±[X]% (where [X] is typically around 10% to account for normal voltage fluctuations in industrial power supplies). A stable power supply is essential for the reliable operation of the module. |

| Communication Ports | It has multiple communication ports, which may include serial ports (such as RS – 232 or RS – 485) and Ethernet ports. The serial ports can be used for connecting to legacy devices or for simple point – to – point communication, while the Ethernet ports provide high – speed data transfer capabilities and are suitable for connecting to larger industrial networks. |

| Data Transfer Rate | For Ethernet ports, the data transfer rate can be up to 10/100 Mbps, depending on the network configuration. For serial ports, the baud rate can be set to values such as 9600, 19200, or 115200 baud, allowing for different levels of data transfer speed. |

| Number of Supported Modules | It can support a certain number of I/O modules and other function modules in the PLC rack. This number depends on the specific design and capabilities of the module, but typically it can handle several to a dozen or more modules, enabling the construction of a comprehensive industrial control system. |

| Operating Temperature | -20°C to 60°C. This wide temperature range ensures that the module can operate reliably in different industrial environments, from cold storage areas to hot manufacturing plants. |

| Dimensions | [Length] x [Width] x [Height] (mm). The compact design is suitable for installation in control cabinets or other industrial enclosures. |

| Weight | [X] kg |

4. Advantages

- Reliability: Built with high – quality components, the IC200CHS022 has a long mean time between failures (MTBF). In a continuous – running industrial process, such as a 24/7 manufacturing line, its reliability ensures minimal downtime and reduced maintenance costs.

- Flexibility: The support for multiple communication protocols and the ability to connect different types of modules make it a flexible solution. It can be easily integrated into existing industrial systems, regardless of the specific communication infrastructure or the types of devices used.

- Scalability: As mentioned earlier, it allows for easy system expansion. This is important for industries that may need to upgrade or modify their automation systems over time to adapt to new production requirements or technological advancements.

5. Application Fields

- Manufacturing: In automotive, electronics, and food processing industries, it can be used to control and monitor the production lines. For example, in an automotive assembly line, it can coordinate the operation of robotic arms, conveyor belts, and quality control systems by facilitating the communication between different PLC modules.

- Energy Sector: In power generation, distribution, and renewable energy systems, it can be used to monitor and control electrical equipment. It can transfer data from sensors in generators, transformers, and power lines to the central control system for real – time monitoring and decision – making.

- Water and Wastewater Treatment: In water treatment plants, it can control the flow of water, the dosing of chemicals, and monitor water quality parameters. It enables the communication between different sensors, pumps, and valves in the treatment process, ensuring the efficient and safe operation of the plant.

6. Selection Considerations

- Compatibility: Ensure that the IC200CHS022 is compatible with your existing IC200 PLC system, including the communication protocols, power supply, and other modules in the rack.

- Communication Requirements: Evaluate your specific communication needs, such as the required data transfer rate, the number of devices to be connected, and the type of communication protocol. Make sure the module can meet these requirements.

- Budget: Compare the cost of the IC200CHS022 with other similar communication modules in the market. Consider the long – term benefits of reliability, flexibility, and scalability when making a decision.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, communication ports, and other modules are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and data transfer rates. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer the IC200CHS022 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide