Description

1. Product Overview

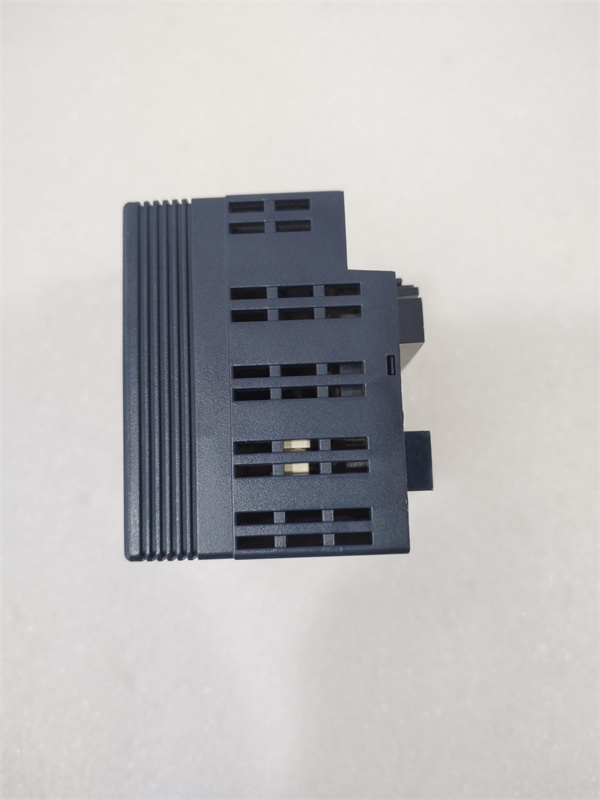

The IC200ALG320J is a module commonly used in industrial automation systems, specifically as part of a Programmable Logic Controller (PLC) setup. It is an analog input/output module, which means it plays a crucial role in handling continuous – valued signals from sensors and sending appropriate control signals to actuators.

2. Functionality

- Analog Input Handling: This module can receive analog signals from various types of sensors. These sensors are used to measure physical quantities such as temperature, pressure, flow rate, and level. For example, a thermocouple can convert temperature into a small voltage signal, and the IC200ALG320J can accept and process this signal. It then digitizes the analog input so that the PLC’s central processing unit can analyze and use the data for decision – making.

- Analog Output Generation: Based on the control algorithms and decisions made by the PLC, the module can generate analog output signals. These signals are used to control devices that require a variable – level input, such as variable – speed drives for motors or proportional valves for fluid control. For instance, it can send a specific voltage or current signal to a motor drive to adjust the speed of the motor according to the process requirements.

- Signal Conditioning: Before digitizing the analog inputs and generating analog outputs, the module performs signal conditioning. This includes filtering out electrical noise, amplifying weak signals, and linearizing non – linear sensor outputs. Signal conditioning ensures that the data received and sent by the module is accurate and reliable.

3. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC ±[X]% (where [X] is typically around 10% to account for normal voltage fluctuations in industrial power supplies). A stable power supply is essential for the proper functioning of the module. |

| Analog Input Channels | [X] channels (for example, 4, 8, or 16). Each channel can be connected to a different analog sensor, allowing the module to monitor multiple physical variables simultaneously. |

| Input Signal Ranges | It supports various standard analog input ranges, such as 4 – 20mA, 0 – 20mA, 0 – 10V, – 10V to + 10V. This flexibility enables it to be compatible with a wide range of analog sensors available in the market. |

| Signal Resolution | [X] bits (e.g., 12 – bit or 16 – bit resolution). A higher – bit resolution means that the module can distinguish smaller changes in the analog input signal, resulting in more accurate measurements. |

| Analog Output Channels | [Y] channels (e.g., 2, 4, or 8). These channels are used to send analog control signals to external devices. |

| Output Signal Ranges | Similar to the input ranges, it can output signals in ranges like 4 – 20mA or 0 – 10V. |

| Sampling Rate | [X] samples per second. The sampling rate determines how often the module measures the analog input signal. A higher sampling rate is beneficial for monitoring rapidly changing process variables. |

| Communication Interface | It communicates with the PLC’s central processing unit using a specific internal communication protocol. This allows for seamless data transfer between the module and the PLC for control and monitoring purposes. |

| Operating Temperature | -20°C to 60°C. This wide temperature range ensures that the module can operate reliably in different industrial environments, from cold storage areas to hot manufacturing plants. |

| Dimensions | [Length] x [Width] x [Height] (mm). The compact design is suitable for installation in control cabinets or other industrial enclosures. |

| Weight | [X] kg |

4. Advantages

- High Precision: With its high – resolution analog – to – digital conversion and effective signal conditioning, the IC200ALG320J can provide highly accurate measurements of analog input signals and precise control through analog output signals. In a chemical manufacturing process, it can precisely measure the concentration of chemicals and adjust the flow of reactants accordingly.

- Versatility: The support for multiple input and output signal ranges makes it a versatile solution for different industrial applications. It can be used in diverse industries such as automotive, food and beverage, and power generation.

- Reliability: Built with high – quality components, it has a long mean time between failures (MTBF). In a continuous – running industrial process, such as a 24/7 production line, its reliability ensures minimal downtime and reduced maintenance costs.

5. Application Fields

- Manufacturing: In automotive manufacturing, it can be used to monitor the temperature of engines during the production process, ensuring that the engines are within the proper operating temperature range. In electronics manufacturing, it can measure the voltage and current in circuit boards for quality control.

- Energy Sector: In power plants, it can monitor the pressure, temperature, and flow of steam in turbines. In renewable energy systems, such as solar power plants, it can measure the solar irradiance and the temperature of photovoltaic panels.

- Process Industries: In chemical and pharmaceutical industries, it is used to monitor and control the various process parameters in reactors, distillation columns, and other equipment.

6. Selection Considerations

- Compatibility: Ensure that the IC200ALG320J is compatible with your existing PLC system in terms of communication protocol, power supply, and physical mounting.

- Performance Requirements: Evaluate your specific requirements for the number of input and output channels, signal resolution, sampling rate, and input/output signal ranges. For example, if you need to monitor a large number of process variables, choose a module with more input channels.

- Budget: Compare the cost of the IC200ALG320J with other similar analog I/O modules in the market. Consider the long – term benefits of reliability and performance when making a decision.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, sensors, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and input/output signal ranges. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer the IC200ALG320J and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide