Description

The

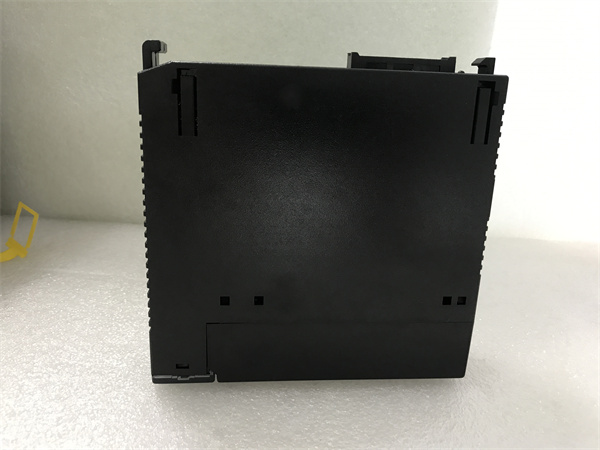

HE693THM166 is a significant component in the realm of industrial automation, specifically designed for handling temperature – related control and monitoring tasks. This module is part of a well – established product line that is known for its precision and reliability in industrial settings.

The core function of the HE693THM166 is to accurately measure temperature values from various sensors and convert them into digital signals that can be processed by a programmable logic controller (PLC). These temperature readings are crucial for maintaining the proper operation of industrial processes, as many manufacturing and processing operations are highly sensitive to temperature changes.

In terms of its use, the HE693THM166 can be found in a wide range of industries. For example, in the chemical industry, it is used to monitor the temperature of reactors to ensure that chemical reactions occur under the right conditions. In the food processing industry, it helps in maintaining the optimal temperature during cooking, cooling, and storage processes.

One of the key advantages of the HE693THM166 is its high – level of accuracy. It can measure temperature with a very small margin of error, which is essential for processes that require strict temperature control. Additionally, it has a fast response time, allowing it to quickly detect and report any temperature fluctuations. This enables timely adjustments to be made in the industrial process, preventing potential issues such as product defects or equipment failures.

| Parameter |

Details |

| Power Supply |

24V DC (±10%) |

| Input Types |

Thermocouples (e.g., J, K, T types) and RTDs (e.g., Pt100) |

| Number of Input Channels |

16 channels |

| Temperature Measurement Range |

– 200°C to 1370°C (depending on the sensor type) |

| Resolution |

0.1°C |

| Accuracy |

±0.5°C |

| Communication Interface |

RS – 485, compatible with Modbus RTU protocol |

| Compatibility |

Compatible with specific series of PLCs |

| Operating Temperature |

– 20°C to 60°C |

| Storage Temperature |

– 40°C to 85°C |

- High Accuracy: The HE693THM166 offers an accuracy of ±0.5°C, which is much higher than many similar products in the market. In a pharmaceutical manufacturing plant, this high accuracy ensures that the temperature – sensitive drugs are produced under the correct temperature conditions, reducing the risk of product spoilage.

- Multiple Input Types: It supports both thermocouples and RTDs, providing users with flexibility in choosing the most suitable temperature sensor for their application. In a power generation plant, different parts of the system may require different types of sensors, and the HE693THM166 can accommodate these diverse needs.

- Fast Response Time: With a short response time, it can quickly detect temperature changes. In a metal – smelting process, where temperature changes can be rapid, the HE693THM166 can promptly report these changes, allowing operators to take immediate action.

- Application Areas: The HE693THM166 is widely used in industries such as chemical, food processing, power generation, and pharmaceutical manufacturing. It is also applicable in HVAC systems for maintaining proper indoor temperatures.

- Application Case: In a large – scale brewery, the HE693THM166 was installed to monitor the temperature during the fermentation process. The accurate temperature measurement provided by the module ensured that the yeast activity was optimal, resulting in a consistent and high – quality beer production. Before using the HE693THM166, the brewery had some batches with inconsistent flavor due to temperature variations. After its installation, the percentage of defective batches decreased from 5% to less than 1%.

Compared to similar products in the market, the HE693THM166 stands out with its high accuracy and multiple input type support. While some competing modules may offer only a single type of temperature sensor input, the HE693THM166’s ability to accept both thermocouples and RTDs gives it a significant advantage. Additionally, its fast response time is better than many of its counterparts, which is crucial for real – time temperature control in industrial processes.

- Compatibility: Ensure that the HE693THM166 is compatible with your existing PLC system. Check the communication protocols, power supply requirements, and the number of available input channels.

- Temperature Range: Consider the temperature range required for your application. Make sure the HE693THM166 can cover the entire range with the desired accuracy.

- Installation Environment: Evaluate the operating and storage temperatures of the installation site. The HE693THM166 has a specified temperature range, and extreme conditions may require additional protection or a different module.

- Budget: Compare the cost of the HE693THM166 with your budget. While it offers high – end features, make sure it provides a good cost – benefit ratio for your specific needs.

- Installation: Follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Connect the temperature sensors correctly to avoid measurement errors.

- Maintenance: Regularly check the module for any signs of damage or malfunction. Clean the module to prevent dust accumulation, which may affect its performance.

- Safety: When working with the HE693THM166, follow all safety procedures. Disconnect the power supply before performing any maintenance or repair work to avoid electric shock.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for HE693THM166 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide