Description

The

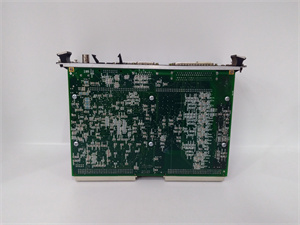

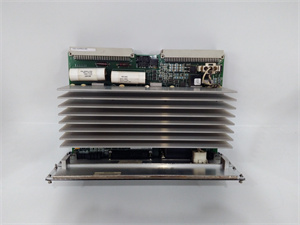

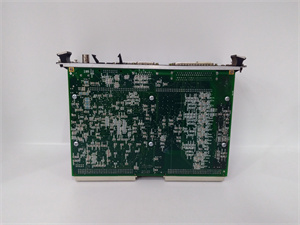

IS215VPROH1BDserves as an emergency turbine protection module with dual functions: contact input isolation and independent overspeed protection. It supports 24 dry contact inputs with group isolation via a TBCI terminal block, protecting the control system from external interference. The module integrates two stacked circuit boards (IS200VPRW top board and base board) with built-in safety features, including thermocouple/analog input support and trip solenoid control via the TREG board. Its compact design (2.1 × 18.8 × 26.2 cm, 0.3 kg) and DIN-rail mounting enable easy integration into Mark VI systems. Key features include LED indicators, Ethernet connectivity, and compliance with industrial standards for harsh environments.

| Parameter |

Specification |

| Brand |

GE Fanuc |

| Series |

Mark VI (Speedtronic Turbine Control) |

| Type |

Emergency Protection & Communication Module |

| Input Signals |

24 dry contacts (group-isolated) |

| Compatibility |

GE Mark VI systems, TREG/TCI boards |

| Dimensions |

2.1 cm (W) × 18.8 cm (H) × 26.2 cm (D) |

| Weight |

0.3 kg (0.66 lbs) |

| Power Supply |

24VDC (via TREG board) |

| Protection Functions |

Emergency overspeed, sync check, trip solenoid control |

| Communication |

Ethernet (via faceplate connectors) |

| Mounting |

DIN rail (integrated with Mark VI chassis) |

IS215VPROH1BD

- Dual Redundancy: Independent emergency protection system separate from the main control system, reducing single points of failure.

- Contact Isolation: 24 isolated dry contact inputs prevent signal interference and protect against voltage spikes.

- Hot-Swap Capability: Modular design allows maintenance without system shutdown, minimizing downtime.

- Harsh Environment Resilience: Industrial-grade components (polyester capacitors, carbon composite resistors) ensure operation in extreme temperatures (0°C to +55°C) and high-vibration settings.

- Testability: Manual and software-initiated trip solenoid tests validate system readiness (e.g., quarterly safety checks in power plants).

- Industry: Power generation (gas/steam turbines), oil & gas (pump stations), manufacturing (rotating machinery).

- Case Study: A European power plant deployed IS215VPROH1BD in a dual-module configuration for its 500MW gas turbine. The module’s redundant overspeed protection detected a 110% speed deviation during a grid fault, triggering a safe shutdown within 50ms—preventing catastrophic damage and reducing repair costs by $2M.

Compared to standard turbine protection modules:

- Isolation Depth: 24-group isolation (vs. 12–16 groups in most alternatives).

- Redundancy Architecture: True independent protection circuit (vs. shared logic in legacy systems).

- Integration Flexibility: Native Mark VI compatibility (no adapters required vs. third-party modules).

- Safety Compliance: Meets ISO 13709 (turbine control) and IEC 61508 (SIL 2) standards for critical applications.

IS215VPROH1BD

- System Type: Use with GE Mark VI turbines (e.g., Frame 6/7) requiring emergency overspeed protection.

- Redundancy Needs: Pair with a second IS215VPROH1BD for N+1 redundancy in high-risk installations (e.g., offshore platforms).

- Environment: Ensure adequate ventilation; derate performance in >50°C environments.

- Expansion: Combine with TREG/TCI boards for full turbine trip system integration.

- Installation:

- Follow ESD protocols; use anti-static gloves.

- Secure terminal block connections (torque: 0.5–0.7 N·m) to prevent loose contacts.

- Maintenance:

- Inspect capacitors for swelling every 3 years (expected lifespan: 10 years).

- Verify trip solenoid response time (<100ms) during annual system tests.

- Safety:

- Disconnect power before replacing modules (24VDC isolation required).

- Do not expose to water or conductive dust; IP20-rated (indoor use only).

声明Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

IS215VPROH1BD and GE Fanuc Mark VI spare parts. We offer certified modules, technical support, and customized solutions for turbine control systems. Visit our website

www.xydcontrol.com or contact us for pricing and compatibility guidance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide