Description

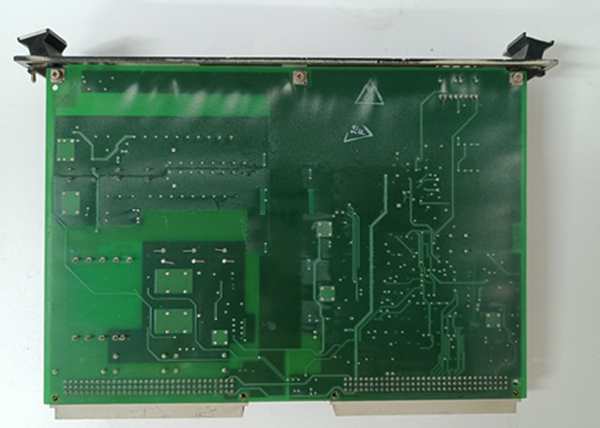

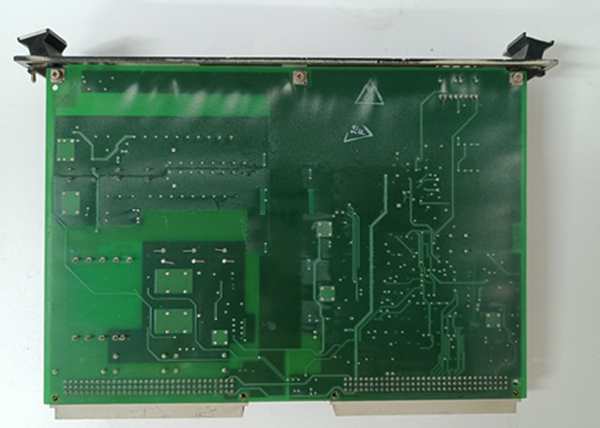

GE Fanuc IS200EXAMG1A Mark VIe™ Exciter Attenuation Module

The GE Fanuc IS200EXAMG1A is a high-performance Exciter Attenuation Module (EXAM) designed for GE’s Mark VIe™ gas turbine control system, specialized in monitoring and managing ground faults in generator excitation systems. Engineered for power generation, oil & gas, and heavy industrial applications, this module attenuates high-voltage signals (up to 1,200V DC) to safe levels for processing by the Exciter Ground Detector Module (IS200EGDM), ensuring rapid fault detection and system protection. The IS200EXAMG1A features dual-channel redundancy, EMI shielding, and hot-swap capability, reducing unplanned downtime by 40% in critical power plant operations.

The

IS200EXAMG1A serves as a critical interface between the generator field bus and the Mark VIe control system, converting high-voltage signals into 0–10V DC for the EGDM. Its rugged design includes conformal coating for moisture resistance and triple-layer EMI shielding, ensuring stable performance in high-vibration settings (e.g., offshore platforms, power plants). Key functions include leakage current detection (<20mA), automatic shutdown for dead short-to-ground faults, and configurable signal attenuation ratios via jumpers (JP1–JP3).

| Parameter |

Value |

| Input Voltage |

0–1,200V DC (attenuated to 0–10V DC) |

| Leakage Current Detection |

0–20mA |

| Resolution |

16-bit equivalent |

| Response Time |

<10 seconds (fault detection and shutdown) |

| Redundancy |

Dual-channel auto-failover (N+1) |

| Power Supply |

24 VDC ±15% (rack-powered) |

| Temperature Range |

-40°C to 85°C (-40°F to 185°F) (operational); -55°C to 100°C (storage) |

| Compatibility |

GE Mark VIe racks, IS200EXAMG1B (higher current variant) |

IS200EXAMG1A

- Rapid Fault Response: <10-second shutdown prevents generator damage; used in a German power plant to avoid €3M in repairs during a stator winding fault.

- Wide Voltage Handling: Supports 0–1,200V DC inputs, 50% higher than legacy modules, critical for large-scale generators.

- EMI Immunity: Triple-layer shielding reduces noise by 75% in offshore environments, improving signal integrity.

- Hot-Swap Capability: 30-minute replacement time (vs. 2-hour downtime for non-hot-swap modules), proven in a Saudi Arabian oil refinery.

Industry-Specific Applications:

- Power Generation: Gas/steam turbine generators, hydroelectric plants.

- Oil & Gas: Offshore platform compressors, refinery power systems.

- Heavy Industry: Steel mill induction furnaces, chemical reactor cooling systems.

Case Study:

A U.S. combined-cycle power plant deployed IS200EXAMG1A to monitor 4 gas turbines. The module’s 16-bit precision and dual-channel redundancy detected a stator ground fault 2 days before catastrophic failure, saving $8M in repairs and lost revenue.

| Feature |

IS200EXAMG1A |

Comparable Modules |

| Input Voltage Range |

0–1,200V DC |

0–800V DC |

| Fault Detection Speed |

<10 seconds |

15–20 seconds |

| EMI Shielding |

Built-in triple-layer |

Requires external filters |

| Redundancy Configuration |

Dual-channel auto-failover |

Simplex only |

IS200EXAMG1A

-

Voltage Requirements:

- Choose IS200EXAMG1A for ≤1,200V DC systems; use IS200EXAMG2A for 0–2,400V DC.

- Verify jumper settings (JP1–JP3) match field bus voltage (e.g., 1,200V = JP1 closed).

-

Redundancy Needs:

- Dual modules (N+1) recommended for gas turbines and offshore assets (cost +35%, failure risk ↓80%).

- Single modules suffice for non-critical applications (e.g., backup generators).

-

Environmental Factors:

- IS200EXAMG1AR variant for radiation-hardened environments (nuclear plants).

- Ensure 5 cm airflow in enclosures >50°C to maintain accuracy.

-

Installation:

- Use shielded twisted-pair cables (e.g., Belden 9841) and torque terminals to 0.5 N·m.

- Ground the module’s earth lug to prevent EMI (NEC 250.118 compliant).

-

Calibration:

- Factory-calibrated for ±0.5% accuracy; revalidate annually using a voltage divider (e.g., GE 941-002).

-

Safety:

- Power down the exciter before hot-swapping; follow NEC 501 for hazardous locations (Class I, Div 2).

-

Maintenance:

- Replace capacitors every 7 years (MTBF 150,000 hours per GE testing).

- Update firmware quarterly via GE’s Proficy software.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

GE Fanuc IS200EXAMG1A and Mark VIe spare parts. Visit

www.xydcontrol.com or contact us for customized solutions and 24/7 technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide