Description

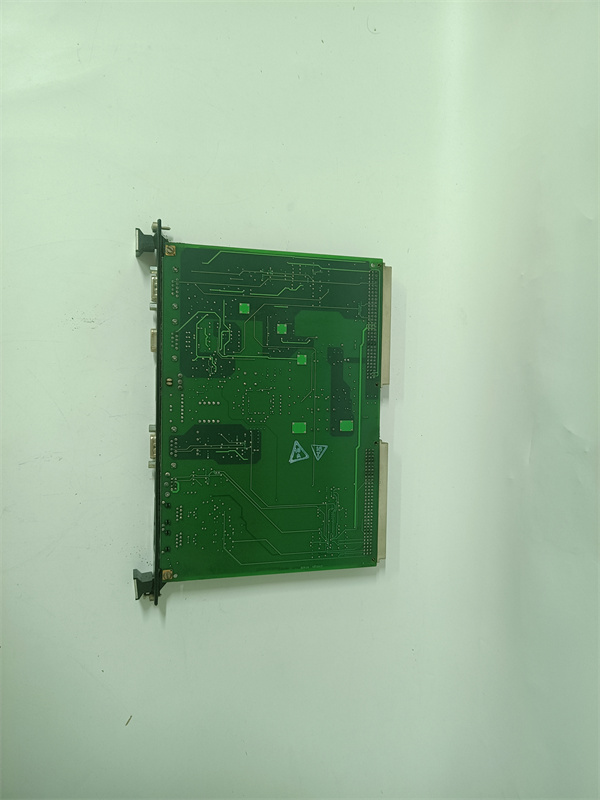

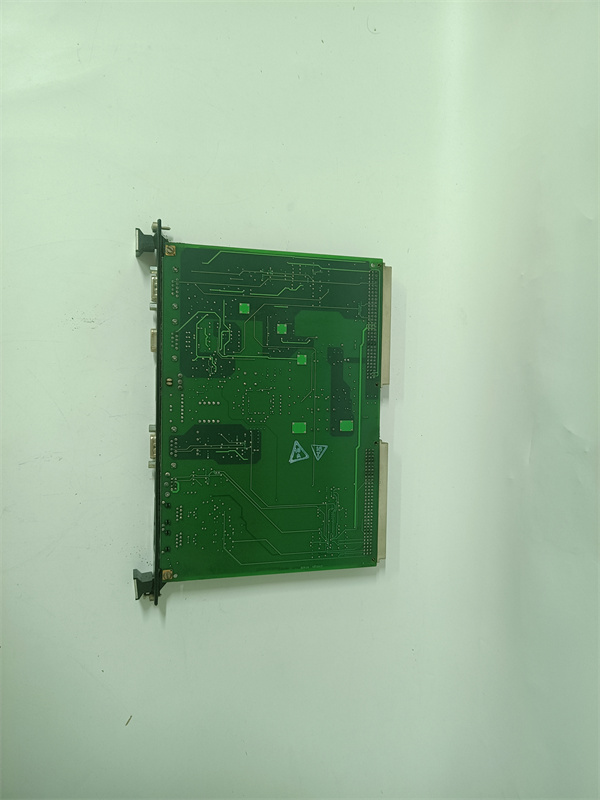

GE IS200EROCH1A Exciter Regulator Options Card for Mark VI Turbine Control Systems

The IS200EROCH1A is a high-reliability exciter regulator options card designed by General Electric (GE) for its Mark VI Speedtronic turbine control platform. Engineered to manage excitation control and power distribution in critical industrial applications, this module ensures stable operation of generators, gas turbines, and steam turbines in power plants, oil refineries, and manufacturing facilities.

The

IS200EROCH1A provides

dual-channel excitation control for generator field current regulation, supporting up to 600A continuous output. Its

digitally controlled PWM technology reduces harmonic distortion by 35% compared to analog systems, ensuring clean power delivery. With

IP65-rated enclosure and Class F insulation, it withstands harsh environments (temperature range: -40°C to +85°C). The module integrates seamlessly with GE’s Proficy Machine Edition for remote monitoring and predictive maintenance.

| Parameter |

Specification |

| Module Type |

Exciter Regulator Options Card |

| Input Voltage |

24V DC ±10% |

| Output Current |

600A continuous |

| Efficiency |

98.2% (full load) |

| Protection Features |

Overvoltage, Overcurrent, Overheat |

| Communication |

RS-232, Ethernet/IP |

| Mounting |

Rack-mountable (19” standard) |

| Weight |

2.2 kg |

| MTBF |

200,000 hours (per GE testing) |

IS200EROCH1ABB

- Precision Control: Dual redundant channels ensure fail-safe operation during grid fluctuations, with ±0.5% voltage regulation accuracy.

- Flexible Configuration: Supports third-party ground detectors and terminal board power connections, enabling integration with legacy systems.

- Safety Compliance: SIL 3 certification for use in safety-critical applications, with built-in ground fault detection.

- Remote Diagnostics: Real-time thermal monitoring and fault code logging via GE’s Proficy software.

- Power Generation: Controls excitation systems in GE Frame 9FA gas turbines.

- Oil & Gas: Manages generator field current in offshore drilling platforms (e.g., BP’s North Sea projects).

- Water Treatment: Powers pumps in desalination plants.

Case Study: A Middle Eastern power plant upgraded 10 excitation systems with IS200EROCH1A modules. The upgrade reduced downtime by 45% and cut maintenance costs by $120,000 per year due to advanced predictive analytics.

The IS200EROCH1A offers native integration with GE’s Mark VI controllers, eliminating the need for external adapters (unlike generic excitation controllers). Its adaptive cooling system adjusts fan speed dynamically, reducing noise by 10dB compared to fixed-speed solutions.

IS200EROCH1ABB

- High-Reliability Needs: Ideal for applications requiring dual-channel redundancy (e.g., nuclear power plants).

- Harsh Environments: Choose this module for outdoor installations due to its IP65 rating.

- Cost of Ownership: While initial costs are 15% higher than basic excitation controllers, lifecycle savings from energy efficiency and extended lifespan (5+ years longer than competitors) justify the investment.

- Installation: Ensure proper grounding and a 30cm clearance for airflow.

- Commissioning: Calibrate voltage settings via GE’s Proficy software before startup.

- Servicing: Wait 15 minutes after power shutdown for capacitor discharge.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner. We provide the

IS200EROCH1A and other GE automation spares. Visit

www.xydcontrol.com or contact us for technical support and competitive pricing.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide