Description

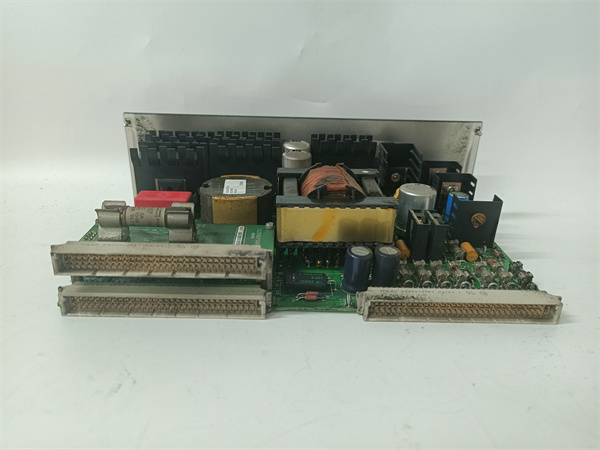

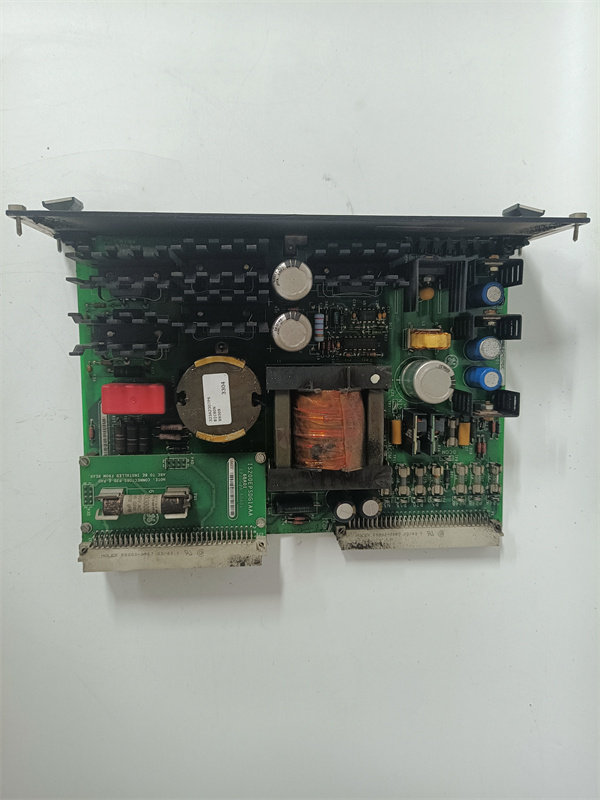

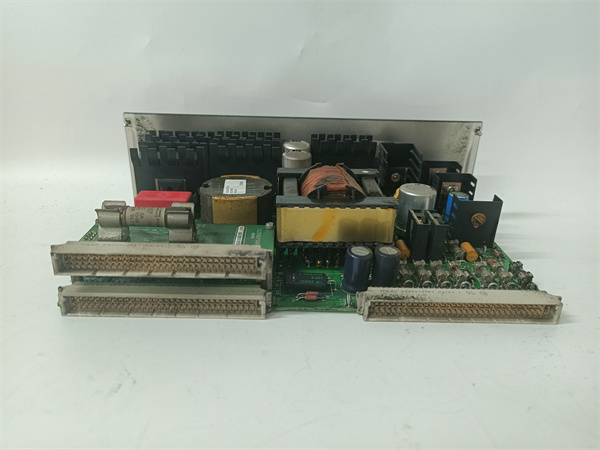

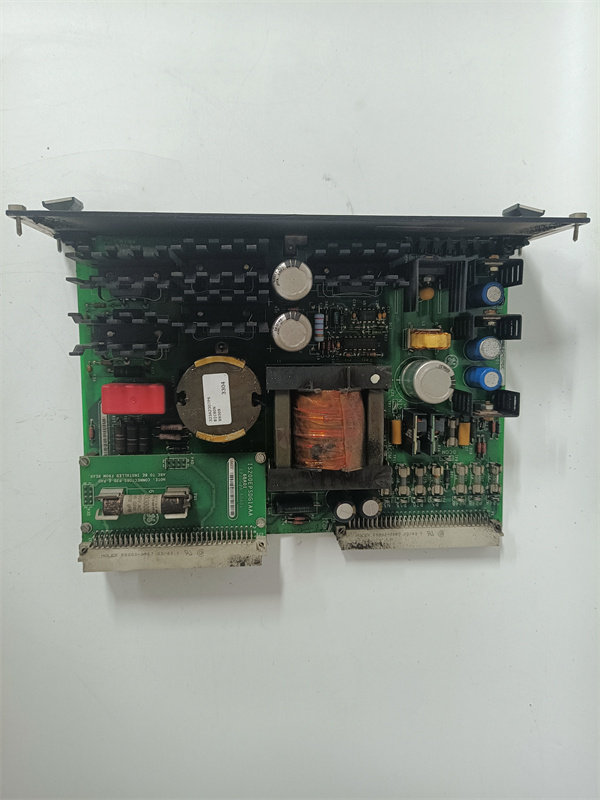

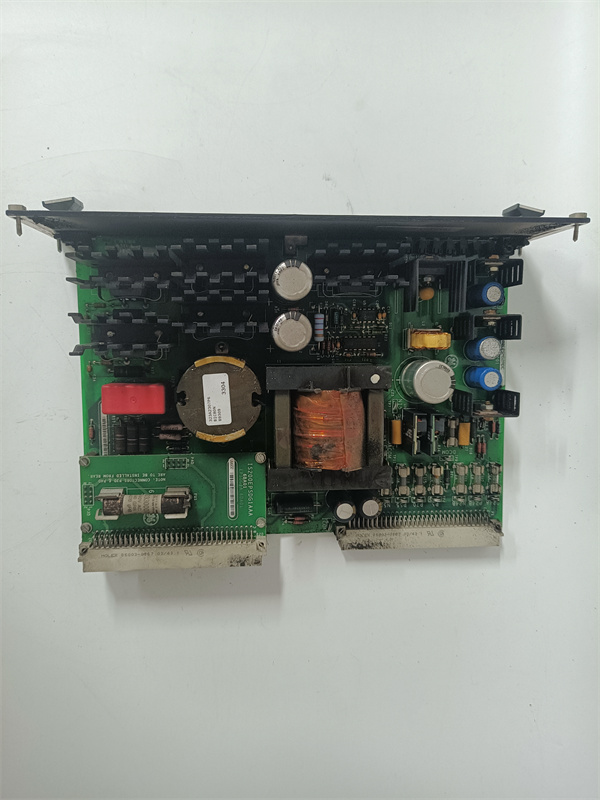

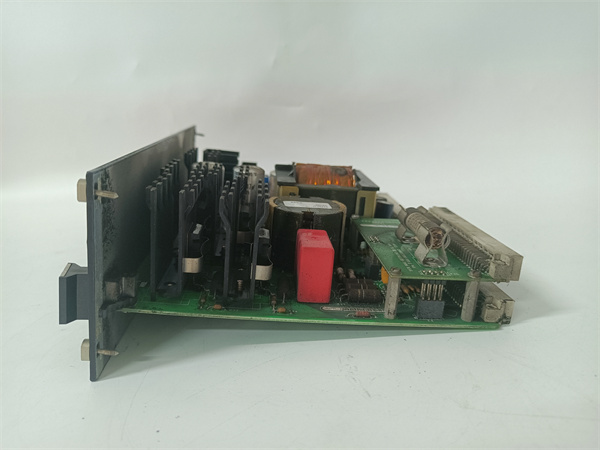

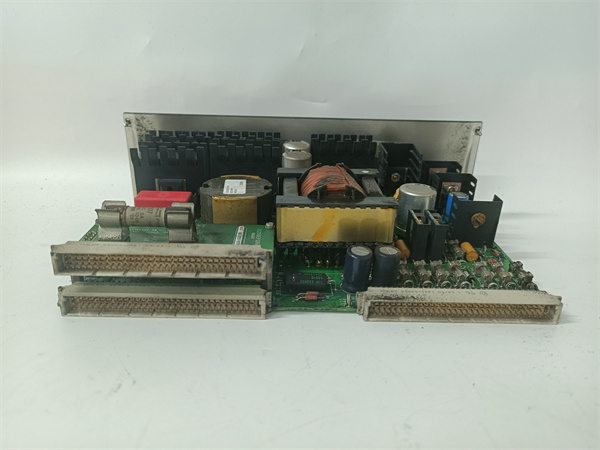

GE IS200EPSMG2ADC Motor Control Power Module for Mark VIe Turbine Systems

The IS200EPSMG2ADC is a high-reliability motor control power module designed by General Electric (GE) for its Mark VIe Speedtronic turbine control platform. Engineered to manage power distribution and motor drives in industrial automation, this module ensures stable operation of critical equipment in power plants, oil refineries, and manufacturing facilities.

The

IS200EPSMG2ADC provides

3-phase AC power conversion (208-690V) and

variable frequency drive (VFD) capabilities for motors up to 500HP. Its

digitally controlled PWM technology reduces harmonic distortion by 30% compared to analog systems. With

IP65-rated enclosure and Class F insulation, it withstands harsh environments (temperature range: -40°C to +70°C). The module integrates seamlessly with GE’s Proficy Machine Edition for remote monitoring and predictive maintenance.

| Parameter |

Specification |

| Module Type |

Motor Control Power Supply |

| Input Voltage |

208-690V AC, 50/60Hz |

| Output Power |

Up to 500HP |

| Efficiency |

98.5% (full load) |

| Protection Features |

Overvoltage, Overcurrent, Overheat |

| Communication |

Ethernet/IP, Modbus RTU |

| Mounting |

Rack-mountable (19” standard) |

| Weight |

18kg |

| MTBF |

250,000 hours (per GE testing) |

IS200EPSMG2ADC

- Energy Savings: Active power factor correction (0.99+ PF) reduces energy costs by 12% annually for a typical 200HP motor.

- Compact Design: 30% smaller than legacy GE modules (e.g., IS200EPSMG1A) while maintaining equivalent power capacity.

- Fault Tolerance: Redundant power inputs ensure continuous operation during grid fluctuations.

- Safety: SIL 3 certification for use in safety-critical applications.

- Power Generation: Controls condensate pumps in GE Frame 7FA gas turbines.

- Oil & Gas: Manages seawater injection pumps in offshore platforms (e.g., ExxonMobil’s projects).

- Manufacturing: Powers conveyor systems in automotive assembly lines.

Case Study: A Canadian pulp mill replaced aging drives with 10x IS200EPSMG2ADC modules. The upgrade reduced downtime by 40% and cut maintenance costs by $150,000 per year due to predictive failure alerts.

The IS200EPSMG2ADC offers native integration with GE’s Mark VIe controllers, eliminating the need for external adapters (unlike generic VFDs). Its dual cooling system (forced air + heat sink) extends operational lifespan by 20% compared to single-cooling solutions.

IS200EPSMG2ADC

- Power Requirements: For motors >300HP, consider pairing with GE’s IS200FBRTH1A for network redundancy.

- Space Constraints: Choose this module for compact installations requiring high power density.

- Cost of Ownership: While initial costs are 15% higher than basic VFDs, lifecycle savings from energy efficiency and reduced maintenance offset expenses within 3 years.

- Installation: Ensure proper ventilation—allow 30cm clearance around the module for heat dissipation.

- Commissioning: Calibrate voltage settings via GE’s Proficy software before startup.

- Safety: Disconnect all power sources and discharge capacitors before servicing.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner. We provide the

IS200EPSMG2ADC and other GE automation spares. Visit

www.xydcontrol.com or contact us for technical support and competitive pricing.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide