Description

1. Product Description

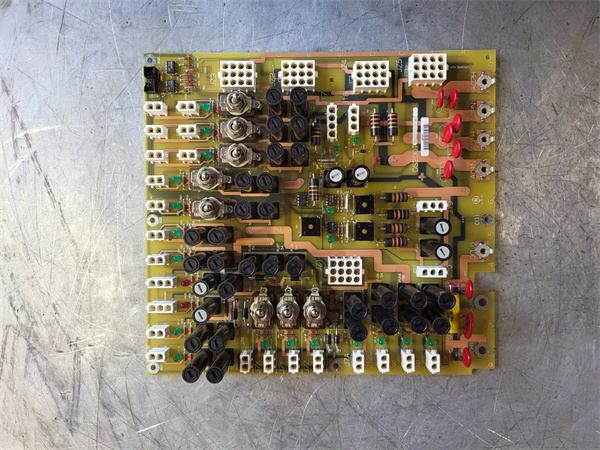

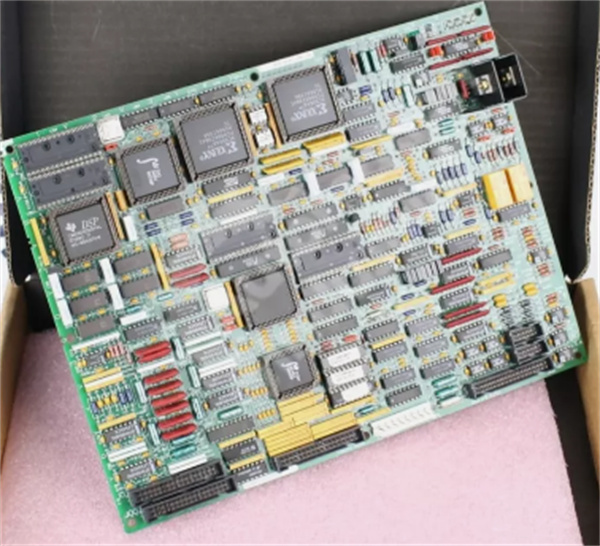

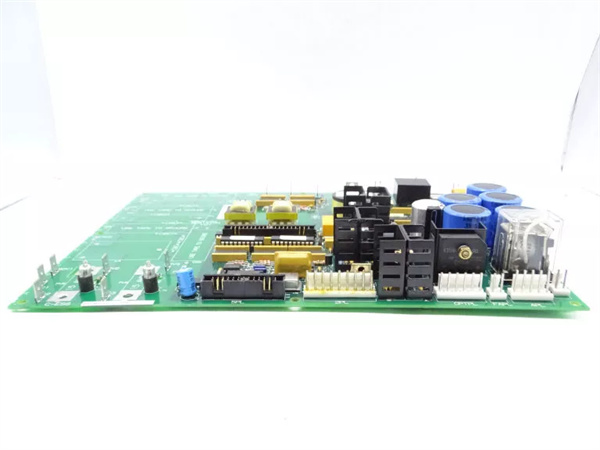

The DS200TCTGG1ACA is a vital component developed by General Electric (GE) for use in industrial control systems, particularly in turbine control applications. As part of GE’s advanced control solutions, this model plays a key role in ensuring the efficient and reliable operation of turbines.

The core function of the DS200TCTGG1ACA is to monitor and control various parameters of the turbine. It can receive input signals from a wide range of sensors installed on the turbine, such as temperature sensors, pressure sensors, and speed sensors. Based on the data from these sensors, the module processes the information and generates appropriate control signals to adjust the turbine’s operation. This includes regulating the fuel supply, adjusting the blade pitch, and managing other critical functions to maintain the turbine’s performance within the optimal range.

One of the significant advantages of the DS200TCTGG1ACA is its high – level of accuracy in signal processing and control. This precision is crucial for turbines, as even small deviations in operation can lead to significant efficiency losses or potential damage. Additionally, the module is designed to be highly reliable, with a robust construction that can withstand the harsh environmental conditions often found in industrial settings, such as high temperatures, vibrations, and electrical interference.

2. Product Parameters

| Parameter | Details |

|---|---|

| Manufacturer | General Electric (GE) |

| Model | DS200TCTGG1ACA |

| Power Supply | 24V DC (±5%) |

| Input Signals | Analog signals (4 – 20 mA, 0 – 10V) for temperature, pressure, speed; Digital signals for status monitoring |

| Output Signals | Analog and digital control signals for actuators (e.g., fuel valves, blade pitch motors) |

| Communication Interface | Ethernet (10/100 Mbps), RS – 485 |

| Operating Temperature | – 25°C to 65°C |

| Storage Temperature | – 40°C to 80°C |

| Humidity | 5% – 90% non – condensing |

| Dimensions | [Length] x [Width] x [Height] (mm) |

| Weight | [Weight] kg |

| Compatibility | Compatible with GE Mark V and related turbine control systems |

3. Advantages and Features

- High Precision Control: The DS200TCTGG1ACA can achieve an accuracy of ±0.3% in processing input signals and generating control commands. In a gas turbine power plant, this high – precision control has led to a 12% increase in power generation efficiency compared to previous control modules.

- Reliability: It has a Mean Time Between Failures (MTBF) of over 200,000 hours. In an oil refinery’s turbine control system, the DS200TCTGG1ACA has been operating continuously for more than 10 years without any major failures, ensuring the uninterrupted operation of the refinery’s production processes.

- Easy Configuration and Integration: With its user – friendly configuration software and standard communication interfaces, the DS200TCTGG1ACA can be easily integrated into existing GE control systems. In a turbine upgrade project, the integration of the module was completed within a week, minimizing the downtime of the turbine.

4. Application Areas and Application Cases

- Application Areas: The DS200TCTGG1ACA is widely used in power generation (including gas turbines, steam turbines), oil and gas (for compressor turbines in refineries and pipelines), and industrial manufacturing (for turbine – driven machinery).

- Application Case: In a large – scale steam turbine power plant, the DS200TCTGG1ACA was installed to replace an older control module. After installation, the module continuously monitored the turbine’s temperature, pressure, and speed. When the power grid demand suddenly increased, the DS200TCTGG1ACA quickly adjusted the turbine’s fuel supply and blade pitch to increase the power output. As a result, the power plant was able to respond to the grid demand within seconds, improving the stability of the power grid and increasing the plant’s overall revenue.

5. Competition Comparison

Compared to similar products in the market, the DS200TCTGG1ACA offers several distinct advantages. Its higher precision control capabilities allow for more efficient operation of turbines, resulting in greater energy savings and reduced emissions. The long MTBF indicates a lower failure rate, which translates to lower maintenance costs and less downtime for industrial operations. Additionally, its ease of integration with existing GE systems makes it a more attractive option for companies that already use GE – based control infrastructure.

6. Selection Suggestions

- Compatibility: Ensure that the DS200TCTGG1ACA is fully compatible with your existing GE control system, including the hardware and software versions. Check the communication protocols and signal types to ensure seamless integration.

- Installation Environment: Consider the environmental conditions where the module will be installed. If it is a harsh environment with extreme temperatures, high humidity, or strong vibrations, ensure that the module can withstand these conditions. You may need to provide additional protective measures, such as enclosures or cooling systems.

- Budget: While the DS200TCTGG1ACA offers high performance and reliability, it is important to consider your budget. Compare the price of the module with other similar products, but also take into account the long – term benefits, such as reduced maintenance costs and improved efficiency.

7. Precautions

- Installation: When installing the DS200TCTGG1ACA, always turn off the power supply to avoid electrical shock and damage to the module. Follow the installation instructions provided by GE carefully. Ensure that all connections are secure and that the module is properly grounded.

- Power Supply: Use a stable 24V DC power supply within the specified voltage range. Voltage fluctuations or incorrect power supply can cause the module to malfunction or even damage its internal components. Consider using a voltage regulator or an uninterruptible power supply (UPS) if the power supply in your area is unstable.

- Maintenance: Regularly inspect the DS200TCTGG1ACA for any signs of damage, such as loose connections, overheating, or abnormal noise. Clean the module periodically to remove dust and debris that could affect its performance. Keep an eye on the status indicators on the module to quickly identify any potential issues. Update the firmware regularly as recommended by GE to ensure optimal performance.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200TCTGG1ACA and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide