Description

1. Product OverviewThe

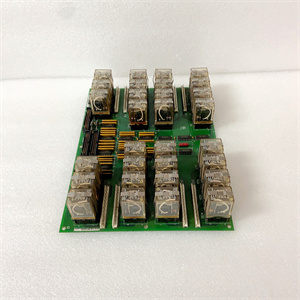

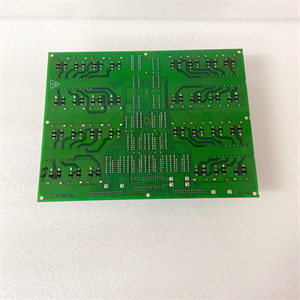

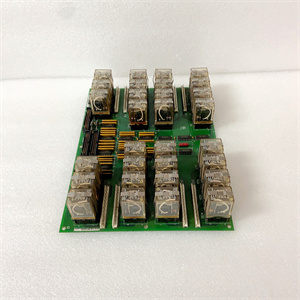

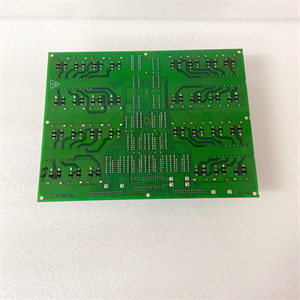

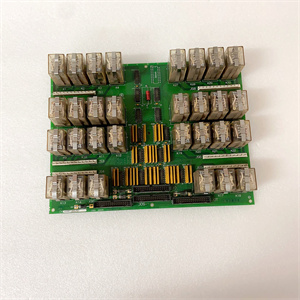

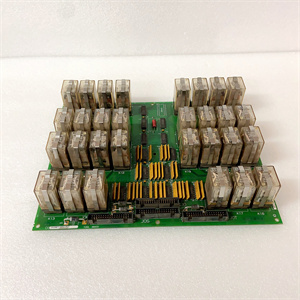

GE Fanuc DS200TCRAG2A is a high-reliability relay output board designed for GE’s Mark V LM gas turbine control systems. As part of the legacy Mark V series, this module plays a critical role in converting digital signals into relay operations for precise control of solenoids, valves, and other industrial actuators. Built with GE’s patented Speedtronic technology, it ensures stable performance in harsh environments, making it ideal for power generation, oil and gas, and industrial automation applications.

2. Key Technical Parameters

| Parameter |

Specification |

| Type |

Relay Output Board |

| Relays |

30 plug-in relays (K1–K30), 0.5A contact rating |

| Core Compatibility |

Q11 (4 relays for gas manifold blow-off valves) and Q51 (18 relays for solenoid power) |

| Connectors |

JS1–JS8 (for terminal board connections), JO (corebus interface) |

| Voltage |

24V DC ±10% (solenoid power via DTBC/DTBD boards) |

| Configuration |

Hardware-only (jumpers on DTBC/DTBD boards) |

| Weight |

1.2 kg |

| Dimensions |

305 mm × 152 mm × 44 mm |

3. Advantages and Features

- Redundant Design: Dual relays in critical cores ensure fail-safe operation.

- Flexible Configuration: Hardware-based setup allows quick adjustments without software programming.

- High Current Handling: Supports solenoid loads up to 0.5A per contact.

- EMI Resistance: Shielded design minimizes interference in high-noise environments.

4. Application Areas and Case Studies

The DS200TCRAG2A is widely used in:

- Power Generation: Gas turbine control systems for valve actuation and safety interlocks.

- Oil and Gas: Refinery processes requiring precise solenoid control.

- Manufacturing: Automated machinery with high-reliability relay switching.

Case Study:

A major energy plant reduced maintenance downtime by 20% by deploying the DS200TCRAG2A in its gas turbine fleet. The board’s hardware-configurable relays simplified troubleshooting and replacement, improving operational efficiency.

5. Competitor Comparison

Compared to alternative relay output modules, the DS200TCRAG2A offers:

- Seamless Integration: Native compatibility with GE’s Mark V LM systems, reducing retrofit costs.

- Higher Relay Density: 30 relays in a compact form factor versus competitors’ 24–28.

- No Software Dependency: Hardware jumpers enable faster configuration than software-based alternatives.

6. Selection Recommendations

- Core Type: Choose Q11 for blow-off valve control or Q51 for solenoid power.

- Relay Capacity: Ensure the 30-relay count matches your application’s I/O requirements.

- Terminal Boards: Pair with GE’s DTBC/DTBD boards for proper voltage distribution.

7. Precautions

- Installation: Verify core positioning (Q11/Q51) and connector alignment before powering up.

- Maintenance: Regularly inspect relay contacts for wear and clean dust from connectors.

- Safety: Disconnect power before modifying hardware jumpers to avoid electrical shocks.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

GE Fanuc DS200TCQAG1BGD and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide