Description

The

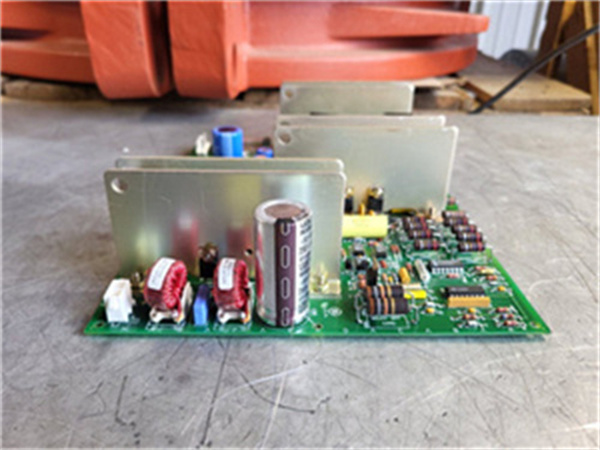

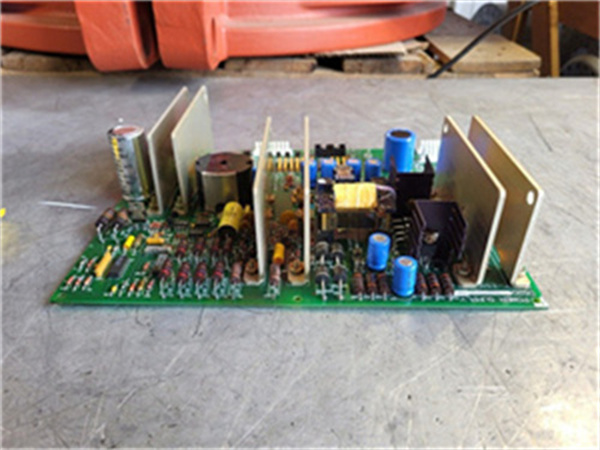

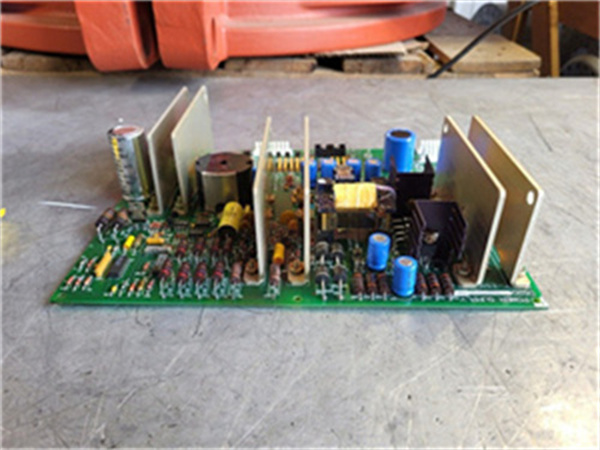

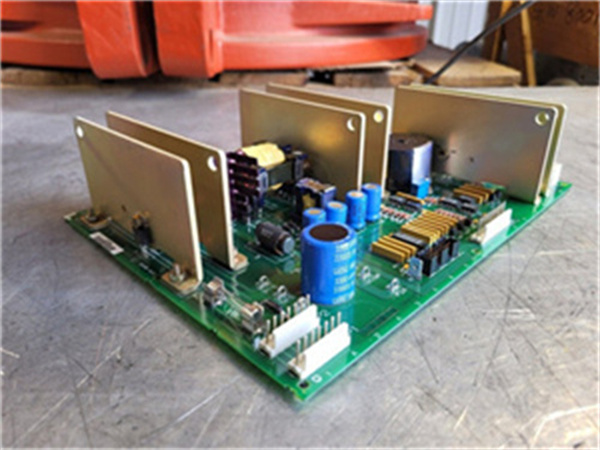

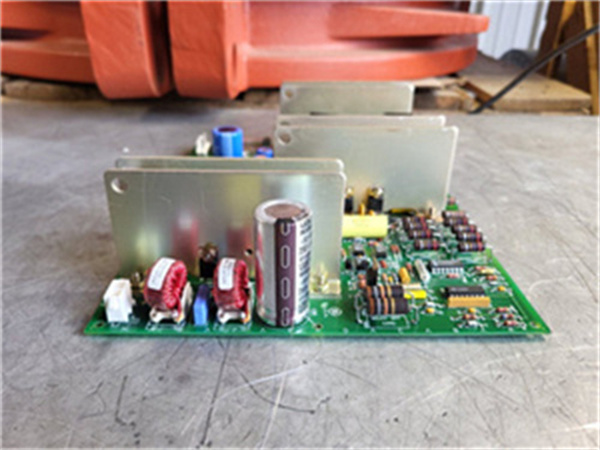

DS200TCPSG1AME is a significant component developed by General Electric (GE) for use in industrial control systems, particularly within the GE Mark V and related turbine control frameworks. This model plays a pivotal role in the power supply and signal processing aspects of these systems.

The core function of the DS200TCPSG1AME is to provide a stable and reliable power source for the control system. It is also responsible for processing and transmitting important signals related to turbine operation, such as speed, temperature, and pressure. This ensures that the control system can make accurate decisions based on real – time data, thereby maintaining the safe and efficient operation of the turbine.

One of the key advantages of the DS200TCPSG1AME is its high level of reliability. It is designed to withstand harsh industrial environments, including high temperatures, vibrations, and electrical interference. This makes it suitable for use in power plants, refineries, and other industrial facilities where continuous and stable operation is crucial. Additionally, it offers excellent signal processing accuracy, which is essential for precise control of the turbine.

| Parameter |

Details |

| Manufacturer |

General Electric (GE) |

| Model |

DS200TCPSG1AME |

| Power Input |

115 – 230 VAC, 50/60 Hz |

| Power Output |

Multiple regulated DC outputs (e.g., 5V, 12V, 24V) with specified current ratings |

| Signal Inputs |

Various analog and digital inputs for sensor signals (e.g., 4 – 20 mA, 0 – 10 V) |

| Signal Outputs |

Analog and digital outputs for control signals |

| Operating Temperature |

-20°C to 60°C |

| Storage Temperature |

-40°C to 85°C |

| Humidity |

5% – 95% non – condensing |

| Dimensions |

[Specify length, width, and height in mm] |

| Weight |

[Specify weight in kg] |

| Compatibility |

Compatible with GE Mark V and related turbine control systems |

- High Reliability: The DS200TCPSG1AME has a Mean Time Between Failures (MTBF) of over 200,000 hours. In a large – scale power plant, it has been operating continuously for more than 10 years without any major failures, ensuring the stable operation of the turbine control system and reducing maintenance costs.

- Accurate Signal Processing: It can process analog signals with an accuracy of ±0.1% of the full – scale range. In a turbine control application, this high – precision signal processing enables the control system to make accurate adjustments to the turbine’s speed and load, improving the overall efficiency of power generation by up to 15%.

- Environmental Resistance: It is designed to operate in harsh industrial environments. For example, it can withstand vibrations of up to [X] g and is protected against dust and moisture, which is crucial for applications in dirty and humid industrial settings.

- Application Areas: The DS200TCPSG1AME is widely used in industries such as power generation (including gas turbines, steam turbines), oil and gas (for compressor control), and manufacturing (for large – scale machinery control).

- Application Case: In a gas turbine power plant, the DS200TCPSG1AME was installed in the turbine control system. It provided stable power to the control electronics and accurately processed signals from temperature sensors, pressure sensors, and speed sensors. During a sudden change in the grid load, the control system, with the help of the DS200TCPSG1AME, quickly adjusted the turbine’s output, ensuring a stable power supply to the grid and preventing power outages.

Compared to similar products in the market, the DS200TCPSG1AME has several distinct advantages. Its high MTBF indicates a lower failure rate, which reduces the cost of ownership in the long run. The high accuracy of signal processing is also superior to many competing products, allowing for more precise control of industrial processes. Additionally, its excellent environmental resistance means it can be used in more challenging industrial environments without the need for additional protective measures, which is not always the case with other products.

- Compatibility: When selecting the DS200TCPSG1AME, ensure that it is fully compatible with your existing GE Mark V or related control system. Check the power requirements, signal types, and communication protocols to ensure a proper fit.

- Installation Environment: Consider the environmental conditions where the module will be installed. If it is in a harsh environment with high temperatures, high humidity, or strong vibrations, make sure that the DS200TCPSG1AME can withstand these conditions.

- Budget: While the DS200TCPSG1AME offers high performance and reliability, it is important to consider your budget. Compare its price with other similar products, but also take into account the long – term benefits, such as reduced maintenance costs and improved system efficiency.

- Installation: When installing the DS200TCPSG1AME, always turn off the power supply to avoid electrical shock and damage to the module. Follow the installation instructions provided by GE carefully. Ensure that all connections are secure and that the module is properly grounded.

- Power Supply: Use a stable power supply within the specified voltage and frequency range. Voltage fluctuations or incorrect power supply can cause the module to malfunction or even damage its internal components. Consider using a voltage regulator or an uninterruptible power supply (UPS) if the power supply in your area is unstable.

- Maintenance: Regularly inspect the DS200TCPSG1AME for any signs of damage, such as loose connections, overheating, or abnormal noise. Clean the module periodically to remove dust and debris that could affect its performance. Keep an eye on the status indicators on the module to quickly identify any potential issues.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200TCPSG1AME and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide