Description

1. Product Description

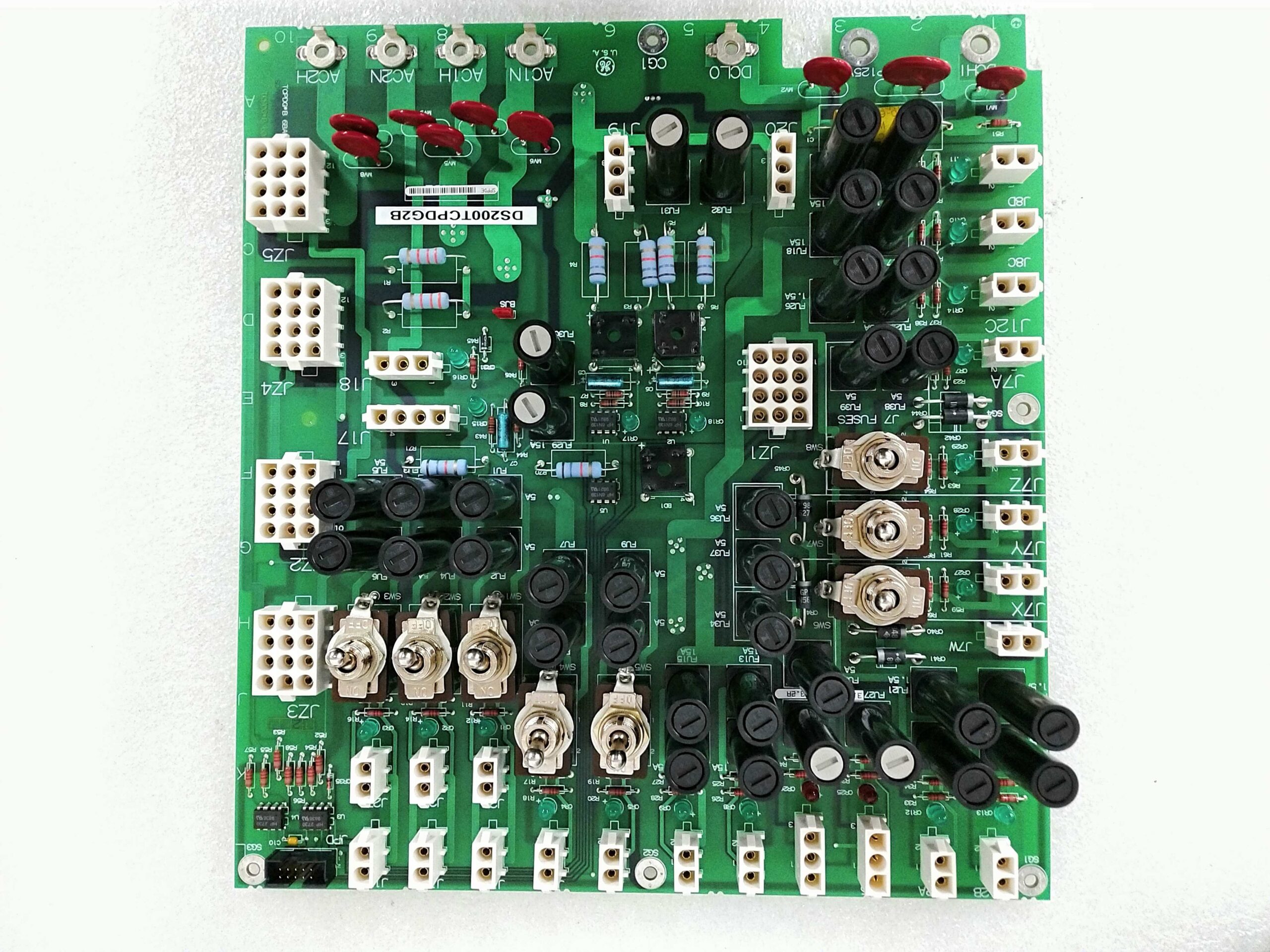

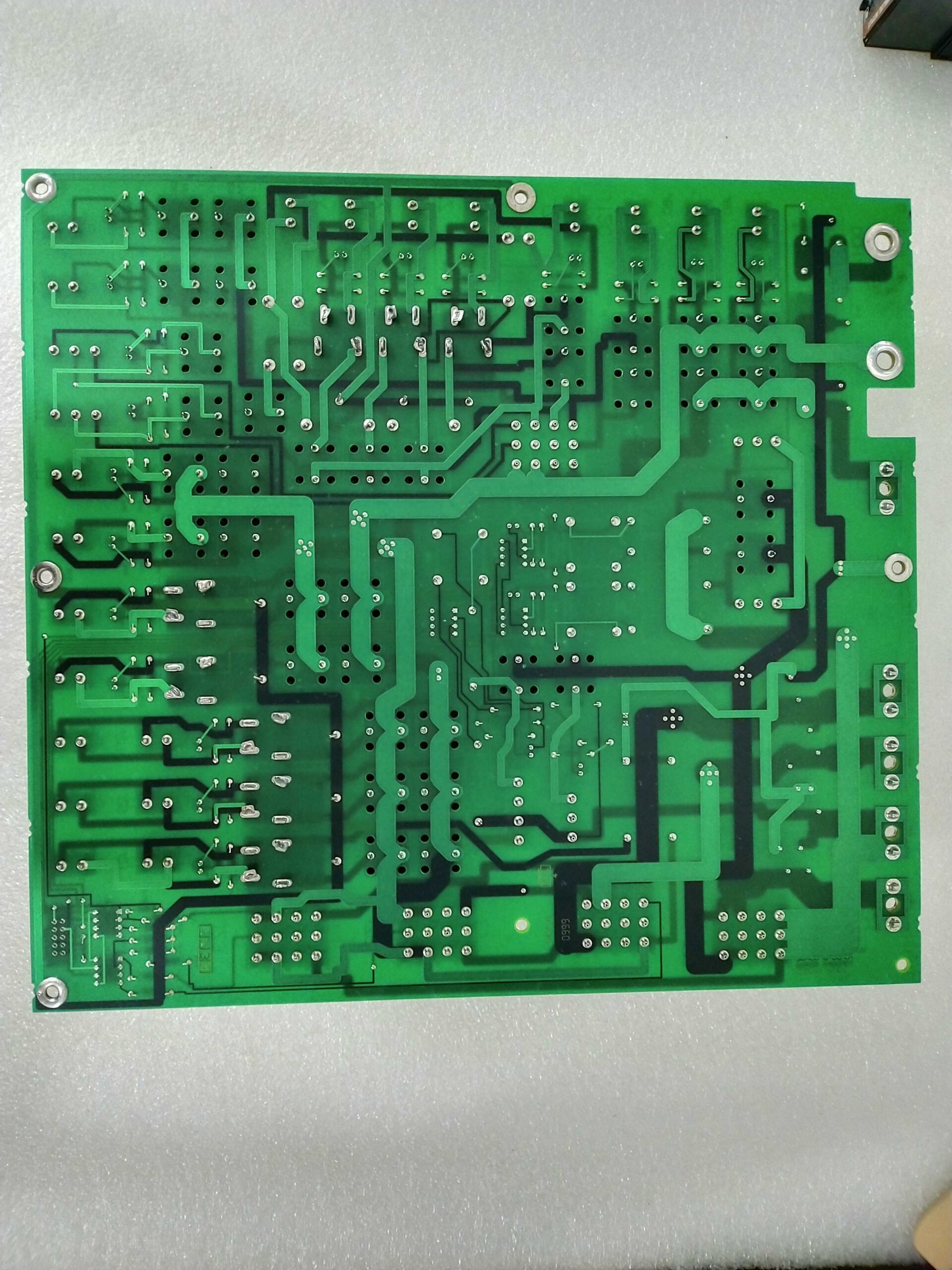

The DS200TCPDG2B is a product from General Electric, commonly used in industrial control systems, especially in power generation and related industrial processes. It is an important module within the control system architecture, playing a key role in data communication and processing.

This module is designed to handle specific control and monitoring tasks. It can interface with various sensors and actuators in the industrial environment, collecting data from sensors such as temperature sensors, pressure sensors, and flow meters. Then, it processes this data according to pre – programmed algorithms and sends appropriate control signals to actuators like valves, motors, and relays. The DS200TCPDG2B helps in maintaining the stability and efficiency of industrial processes by ensuring accurate control and real – time monitoring.

2. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC (±10%) is a common power requirement, which provides a stable source of energy for the module’s operation. |

| Communication Interfaces | It typically supports Ethernet and RS – 485 communication. Ethernet allows for high – speed data transfer and connection to a local area network (LAN), enabling integration with other control systems and monitoring devices. RS – 485 is useful for long – distance communication with other industrial equipment. |

| Input/Output Channels | There are a certain number of digital and analog input/output channels. Digital inputs can detect the on/off states of devices, while analog inputs can measure continuous physical quantities such as voltage, current, or temperature. Digital outputs can control the operation of relays and other binary – controlled devices, and analog outputs can provide variable signals to control actuators. |

| Operating Temperature | The module is designed to operate within a temperature range of – 20°C to 60°C. This wide temperature tolerance allows it to be used in various industrial environments, from cold storage areas to hot manufacturing plants. |

| Storage Temperature | It can be stored within a temperature range of – 40°C to 85°C, ensuring its integrity during transportation and long – term storage. |

3. Advantages and Features

- High – Speed Data Processing: The DS200TCPDG2B is equipped with a powerful processor that can handle large amounts of data quickly. In a power generation plant, it can analyze real – time data from multiple sensors on turbines and generators, enabling rapid decision – making and control actions. For example, it can detect a sudden increase in turbine temperature and immediately adjust the cooling system to prevent overheating.

- Reliability: With a high mean time between failures (MTBF), often exceeding 100,000 hours, this module is highly reliable. In a continuous – operation industrial process, such as a chemical plant, it can run for long periods without breakdowns, reducing production downtime and maintenance costs.

- Flexible Configuration: It allows for flexible configuration of input/output channels and communication parameters. This flexibility enables it to be customized to different industrial applications. For instance, in a water treatment plant, it can be configured to monitor and control specific water quality parameters and the operation of pumps and valves.

4. Application Fields and Application Cases

- Application Fields:

- Power Generation: In thermal, hydro, and gas – fired power plants, it is used to monitor and control the operation of generators, turbines, and other power – related equipment. It helps in optimizing power output, ensuring grid stability, and protecting equipment from damage.

- Industrial Manufacturing: In manufacturing processes such as automotive production, steelmaking, and food processing, it can control the operation of production lines, monitor quality parameters, and manage the flow of materials.

- Oil and Gas: In the oil and gas industry, it can be used for pipeline monitoring, well – head control, and refinery process control.

- Application Case: In a thermal power plant, the DS200TCPDG2B is used to monitor the steam temperature and pressure in the boiler. It receives data from sensors installed in the boiler and compares it with the set – point values. If the temperature or pressure deviates from the normal range, it sends control signals to adjust the fuel supply and the opening of steam valves. As a result, the power plant can operate more efficiently, with reduced fuel consumption and improved power generation efficiency.

5. Competitor Comparison

Compared to some competing products in the market, the DS200TCPDG2B offers better data processing speed. Some competitors may have slower processors, which can lead to delays in data analysis and control actions. In terms of reliability, its high MTBF gives it an edge over products with shorter failure intervals. Additionally, its flexible configuration options make it more adaptable to different industrial requirements compared to some less – customizable competitors.

6. Selection Suggestions

- Compatibility: Ensure that the DS200TCPDG2B is compatible with your existing industrial control system. Check the communication protocols, input/output requirements, and power supply specifications to make sure it can integrate seamlessly with other components.

- Performance Requirements: Evaluate your specific data processing and control requirements. If you need high – speed data analysis and real – time control, the DS200TCPDG2B’s high – performance features may be a good fit.

- Budget: Consider your budget constraints. While the DS200TCPDG2B offers high – quality performance and reliability, compare its price with other available options to find the best value for your investment.

7. Precautions

- Installation: Follow the installation instructions provided by the manufacturer carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module. Make sure all connections are secure to avoid signal loss or malfunctions.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage and temperature limits. Regularly monitor the module’s performance and check for any error indicators or abnormal behavior.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris, and checking the integrity of the components. Replace any worn – out parts promptly to maintain the module’s reliability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide DS200TCPDG2B and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide