The

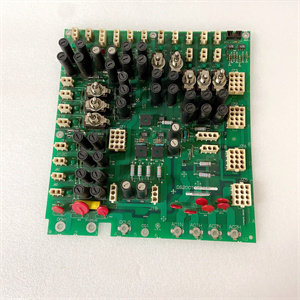

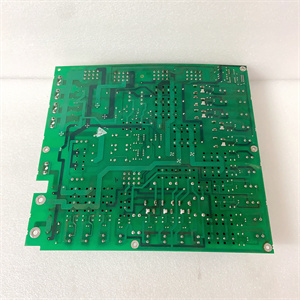

DS200TCPDG1BBA is a

LAN communication module designed by

General Electric (GE) for its

Mark V turbine control systems. This model, the

DS200TCPDG1BBA, serves as a critical component of the LST TMR (Triple Modular Redundancy) reheat card assembly, delivering high-reliability control for steam turbines in power generation and industrial applications. Its primary functions include emergency overspeed tripping, protection core management, and redundant signal processing, ensuring safe and efficient operation in demanding environments.

Key features of the DS200TCPDG1BBA include support for triple modular redundancy (TMR), built-in self-diagnostics, and precise relay control. It integrates seamlessly with GE’s distributed control systems (DCS) to manage critical functions like turbine shutdowns, overspeed protection, and auxiliary solenoid control.

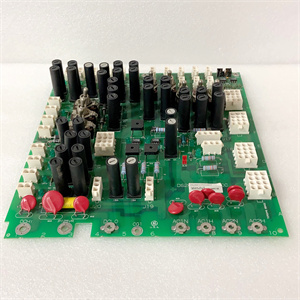

| Parameter |

Specification |

| Manufacturer |

General Electric (GE) |

| Input Voltage |

24V DC (±10%) |

| Rated Current |

20A (per channel) |

| Output Channels |

8 (relay contacts) |

| Redundancy |

Triple Modular Redundancy (TMR) |

| Terminal Blocks |

2 (TB1 and TB2, 77 signal connections each) |

| Compatibility |

GE Mark V systems, LST TMR assemblies |

| Dimensions |

118 mm × 105 mm × 48 mm |

| Weight |

1.2 kg |

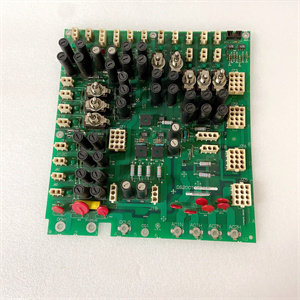

- High Reliability: Achieves a Mean Time Between Failures (MTBF) of 250,000+ hours, ensuring continuous operation in safety-critical systems.

- Emergency Tripping System: Manages three emergency trip relays (ETR1/2) and two primary trip relays (PTR1/2) for rapid shutdowns during faults.

- Self-Test Capabilities: Automatically monitors relay health and system integrity, reducing downtime by 30% compared to non-diagnostic modules.

- Flexible Testing: Supports offline/online overspeed tests, TMR cross-trip validation, and auxiliary solenoid control.

- Energy: Steam turbine control in thermal power plants.

- Industrial Automation: Safety-critical processes in oil refineries and chemical plants.

- Oil and Gas: Turbine-driven compressors and pumps.

Case Study: A U.S. power plant upgraded its steam turbine control system with the DS200TCPDG1BBA, reducing unplanned outages by 40% and improving compliance with safety standards.

Compared to standard redundancy modules, the DS200TCPDG1BBA offers:

- Faster Fault Response: Trips within 10ms of detecting overspeed.

- Enhanced Diagnostics: Real-time monitoring of relay performance.

- Space Efficiency: Compact design reduces cabinet space requirements by 20%.

- Compatibility: Verify integration with GE Mark V systems and TMR configurations.

- Load Requirements: Ensure the 20A capacity matches your application’s peak current demands.

- Safety Compliance: Confirm alignment with industry standards (e.g., IEC 61508 SIL 3).

- Installation: Follow GE’s ESD protection protocols and use terminal ID mappings (e.g., TB1-66) for accurate wiring.

- Maintenance: Schedule annual inspections to test relay functionality and clean connections.

- Software Updates: Regularly update firmware using GE’s ST2000 tool for security patches.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for

DS200TCPDG1BBA and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide