Description

The

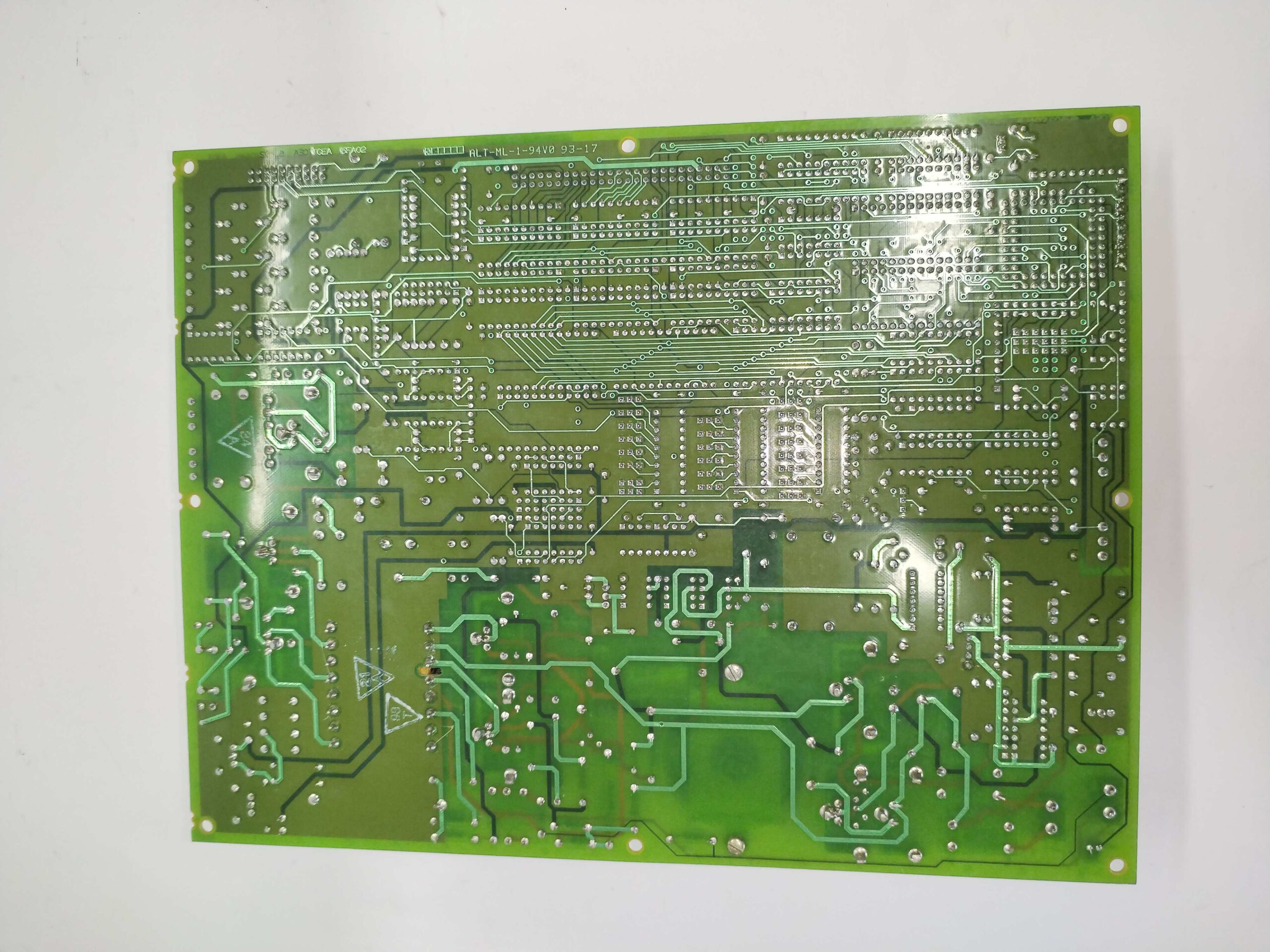

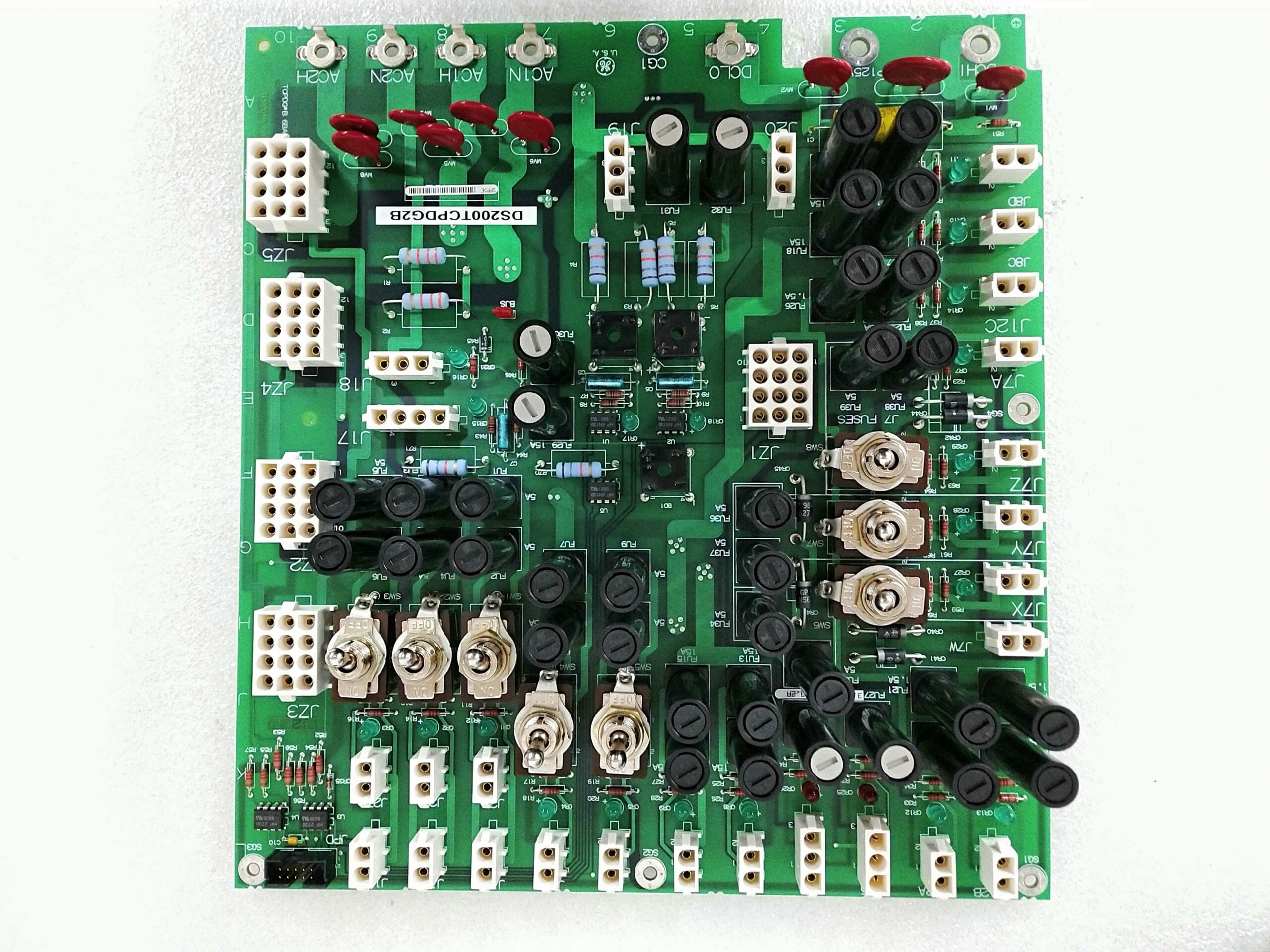

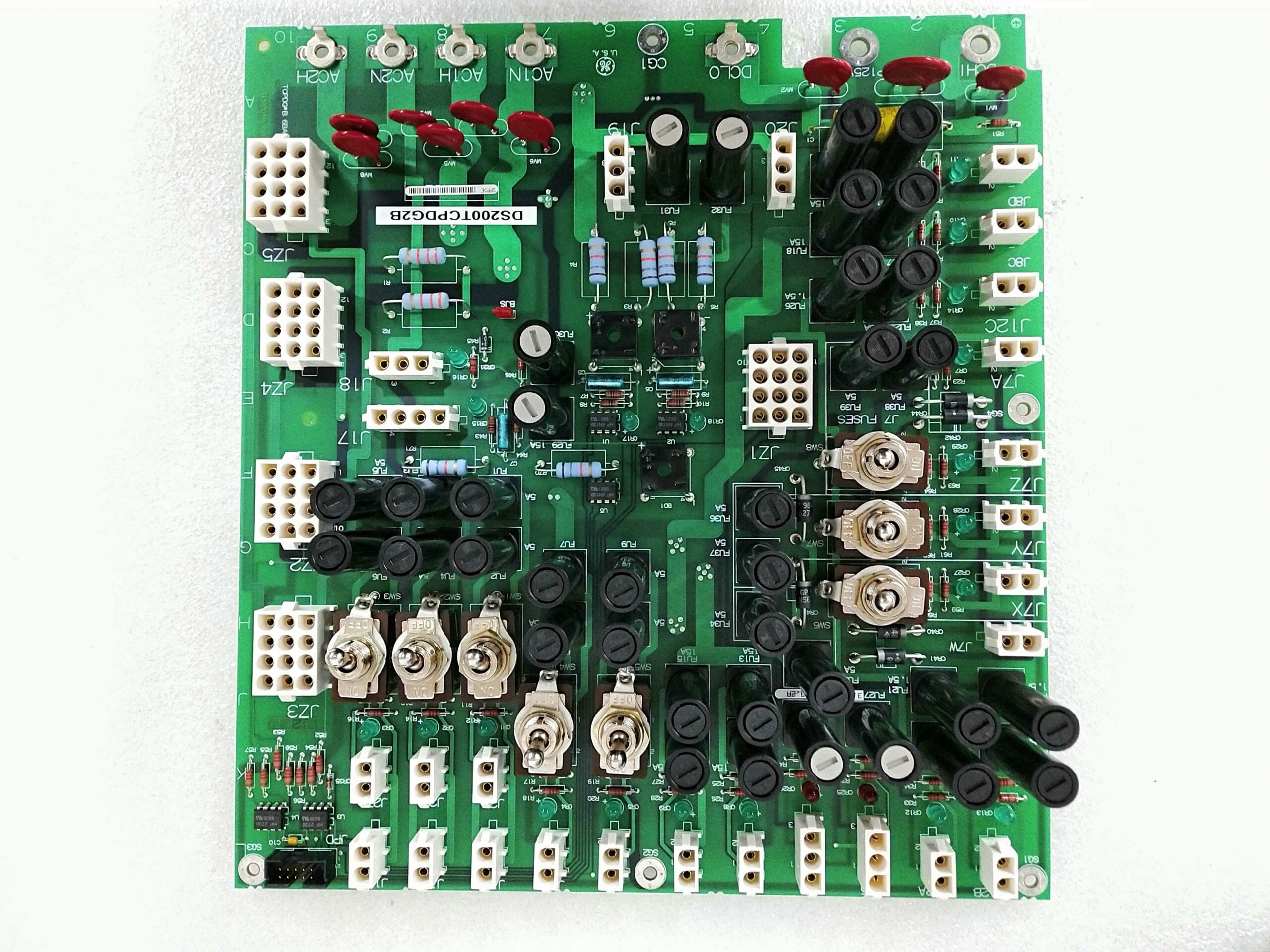

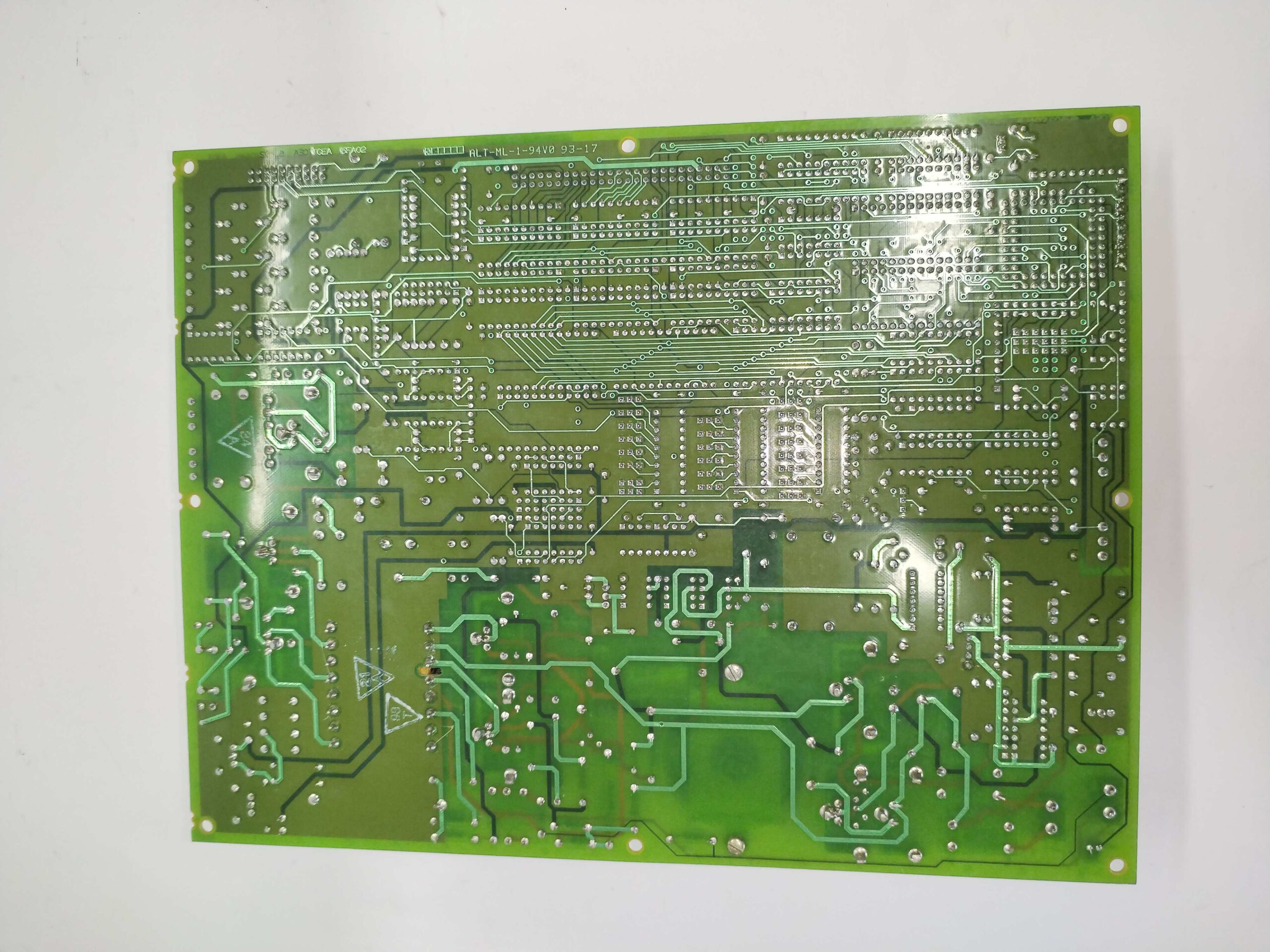

DS200TCCAG1ACA is a

common analog I/O board developed by

General Electric (GE) for its

Mark V turbine control systems. This model, the

DS200TCCAG1ACA, serves as a critical interface for processing analog signals in high-voltage industrial applications, including gas and steam turbine control systems. Its primary role is to manage 4-20mA inputs/outputs, RTD/thermocouple readings, and shaft voltage/current monitoring, ensuring precise data acquisition and control in safety-critical environments.

Key features of the DS200TCCAG1ACA include an 80196 microprocessor, three configurable hardware jumpers (JP1/JP2/JP3), and 50-pin connectors (JCC/JDD) for modular connectivity. It supports artwork revision C (enhanced circuit protection) and functional revision A (optimized signal processing), aligning with GE’s advanced control architectures.

| Parameter |

Specification |

| Manufacturer |

General Electric (GE) |

| Series |

Mark V DS200 |

| Input Voltage |

24V DC (Typical for Mark V systems) |

| Processor |

80196 microprocessor |

| Connector Types |

2×50-pin (JCC/JDD), 2×2-pin (2PL/3PL) |

| Signal Types |

4-20mA, RTD, thermocouple, shaft voltage/current |

| Mounting |

Rack-mounted in turbine control systems |

| Compatibility |

GE Mark V systems, CTBA/TBCA terminal boards |

| Dimensions |

190 mm × 150 mm × 60 mm (Estimated) |

| Weight |

2.1 kg (Estimated) |

- High Precision: Supports ±0.1% accuracy for analog signal conditioning, ensuring reliable data transmission.

- Modular Design: Three hardware jumpers (JP1/JP2/JP3) enable configurable RS232 port activation, oscillator disable, and factory testing.

- Self-Diagnostic: Monitors signal integrity and microprocessor health, reducing unplanned downtime.

- Robust Construction: Normal PCB coating protects against environmental contaminants.

- Energy: Gas and steam turbine control systems in power plants.

- Industrial Automation: Process monitoring in chemical and petrochemical facilities.

- Oil and Gas: Shaft voltage/current monitoring in rotating machinery.

Case Study: A U.S. power plant integrated the DS200TCCAG1ACA into its Mark V system, achieving a 25% improvement in turbine efficiency through precise RTD temperature compensation.

Compared to similar analog I/O boards, the DS200TCCAG1ACA offers:

- Faster Processing: 10ms signal latency for real-time control.

- Enhanced Flexibility: Configurable jumpers for customizing communication protocols.

- Extended Lifespan: 150,000+ hours MTBF in high-temperature environments.

- System Compatibility: Verify integration with GE Mark V systems and terminal boards (CTBA/TBCA).

- Signal Requirements: Ensure support for required analog types (e.g., Type K thermocouples).

- Environmental Conditions: Confirm temperature ratings (0–50°C) match operational needs.

- Installation: Follow GE’s ESD protection guidelines and ensure proper grounding.

- Cooling: Maintain adequate airflow to prevent microprocessor overheating.

- Connector Handling: Avoid bending pins when mating JCC/JDD connectors.

- Software Configuration: Use GE’s HMI tools to program I/O constants for thermocouples and RTDs.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for

DS200TCCAG1ACA and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide